Investigation on Yield of Natural Rubber to Bio-Crude Oil from Hydrothermal Liquefaction Process

Main Article Content

Abstract

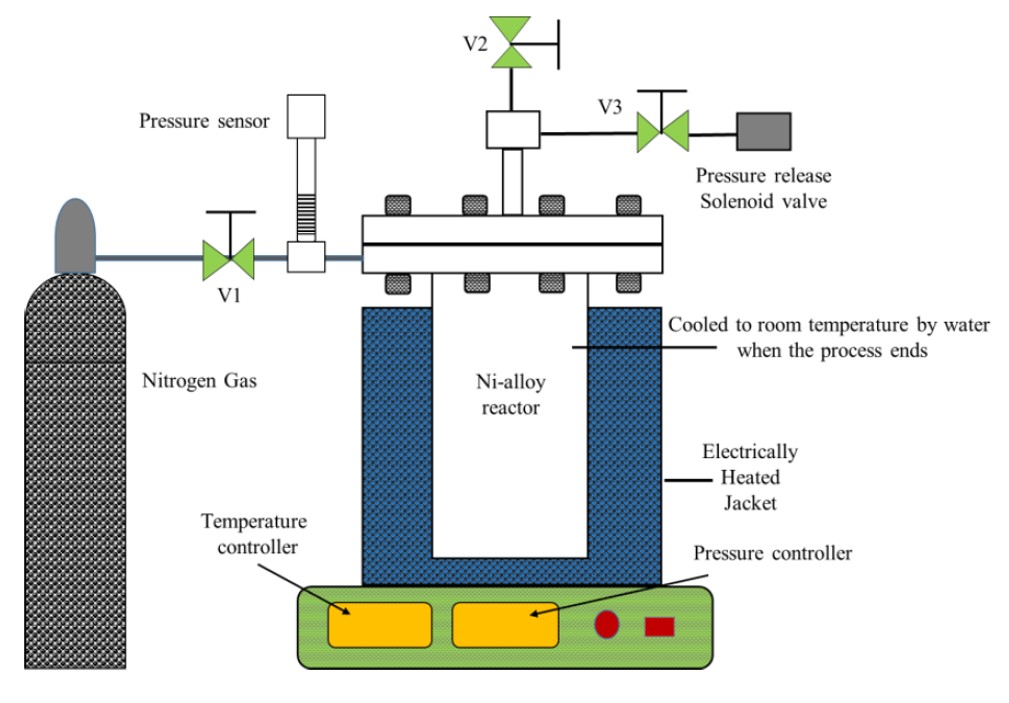

Hydrothermal liquefaction (HTL) requires the presence of water and potentially some catalyst to convert biomass straight to bio-crude oil. In this study, the raw natural rubber is converted to bio-crude oil by the hydrothermal liquefaction process. Experiments are conducted in the autoclave reactor sized of 100 mL at various temperatures ranged between 325-400 °C, with water to natural rubber mass ratios of 1:1 to 5:1, and reacting times of 30-75 minutes. From the investigation, it was found that the highest bio-crude oil yield of 71.4 wt% can be obtained at temperatures of 350 °C, water to natural rubber mass ratios of 4:1, and reacting time of 60 minutes. From the Fourier transform infrared spectroscopy analysis, the major components of the bio-crude oil compound contain high carbon and hydrogen contents which are similar to fossil crude oil in generals. Therefore, it is suggested the synthesis of liquid fuel by the liquefaction process of natural rubber in Thailand is feasible and could be one of the energy potential in the near future.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

References

Gollakota ARK, Kishore N, Gu S. A review on hydrothermal liquefaction of biomass. Renew Sustain Energy Rev. 2018;81:1378-1392.

Xue Y, Chen H, Zhao W, Yang C, Ma P, Han S. A review on the operating conditions of producing bio‐oil from hydrothermal liquefaction of biomass. Int J Energy Res. 2016;40:865-877.

Kruse A, Dahmen N. Water–A magic solvent for biomass conversion. J Supercrit Fluids. 2015;96:36-45.

Usman M, Cheng S, Boonyubol S, Cross JS. From biomass to biocrude: Innovations in hydrothermal liquefaction and upgrading. Energy Convers Manag. 2024;302:118093.

Basu P. Biomass gasification and pyrolysis: practical design and theory. Burlington: Academic press; 2010.

Larsen JW, Hu J. Kerogen chemistry. 8. Hydrous pyrolysis of rundle kerogen: source of the oxygen in CO2 and mineral catalysis. Energy Fuels. 2006;20(1):278-280.

Haider MS, Castello D, Rosendahl LA. Two-stage catalytic hydrotreatment of highly nitrogenous biocrude from continuous hydrothermal liquefaction: a rational design of the stabilization stage. Biomass Bioenergy. 2020;139:105658.

Sandquist J, Tschentscher R, del Alamo Serrano G. Hydrothermal liquefaction of organic resources in biotechnology: how does it work and what can be achieved. Appl Microbiol Biotechnol. 2019;103(2):673-684.

Ocampo E, Beltrán VV, Gómez EA, Ríos LA, Ocampo D. Hydrothermal liquefaction process: review and trends. Curr Res Green Sustain Chem. 2023;7:100382.

Castello D, Pedersen TH, Rosendahl LA. Continuous hydrothermal liquefaction of biomass: a critical review. Energies. 2018;11(11):3165.

Elehinafe FB, Adisa HA, Adesina A, Okedere OB, Unen UE. Economic potentials of pyro bio-oil production from sawdust generated by southwest, Nigeria - a simulation-based approach. Case Stud Chem Environ Eng. 2024;9:100590.

Basu AK. Tyres in mining and allied sectors: status and outlook. Dhanbad: Allied Publishers; 2009.

Wang L, Wang X, Yu J. A comparative study of the pyrolysis and hydrolysis conversion of tire. J Hazard Mater. 2024;468:133724.

Zhang L, Zhou B, Duan P, Wang F, Xu Y. Hydrothermal conversion of scrap tire to liquid fuel. Chem Eng J. 2016;285:157-163.

Sinha S, Agarwal AK, Garg S. Biodiesel development from rice bran oil: transesterification process optimization and fuel characterization. Energy Convers Manag. 2008;49(5):1248-1257.

Morton M. Rubber technology. 3rd ed. New York: Springer; 1999.

Rubber Division, Department of Agriculture, Ministry of Agriculture and Cooperatives. Thailand Rubber Statistics (Vol. 54 No. 4). Bangkok: Rubber Division; 2022.

Nonchana T, Pianthong K. Bio-oil synthesis from cassava pulp via hydrothermal liquefaction: effects of catalysts and operating conditions. Int J Renew Energy Dev. 2020;9(3):329-337.

Ahmad N, Abnisa F, Daud WMAW. Liquefaction of natural rubber to liquid fuels via hydrous pyrolysis. Fuel. 2018;218:227-235.

Chen DT, Perman CA, Riechert ME, Hoven J. Depolymerization of tire and natural rubber using supercritical fluids. J Hazard Mater. 1995;44(1):53-60.

Shah Z, Cataluña Veses R, da Silva R. GC-MS and FTIR analysis of bio-oil obtained from freshwater algae (spirogyra) collected from Freshwater. Int J Environ Agric Res. 2016;2(2):134-141.