Multi-Objective Optimization of Lightweight Inboard Bearing Design for High-Speed Railway Axle

Main Article Content

Abstract

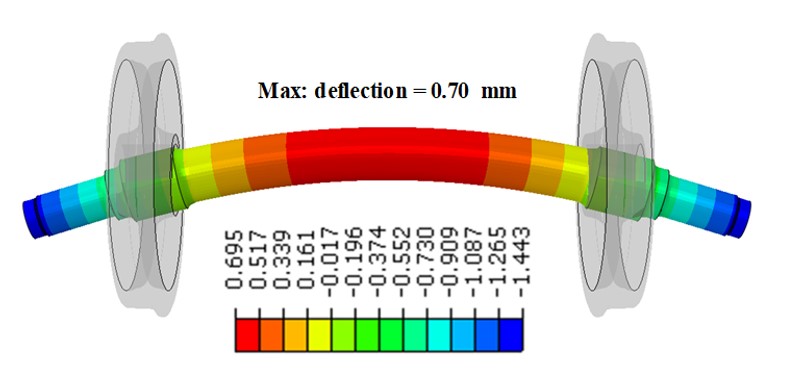

This research delves into the intricate balance between reducing axle weight and maintaining structural integrity in high-speed rail transportation. Focusing on the critical factor of weight reduction in high-speed axle design, the study employs finite element simulations and standard calculations to systematically explore inboard and outboard bearing wheelsets. Particularly noteworthy is the examination of inboard bearing axles, revealing advantages in mass reduction, deflection, and stress mitigation, with an 8% lower weight than outboard bearing axles. Utilizing multi-objective optimization, the research achieves a remarkable 4% reduction in mass and an associated 4% decrease in stress, resulting in a 12% mass reduction compared to traditional axles. The study also enhances fatigue resistance, demonstrated through radial fatigue reverse factor (FRF) analysis. With a detailed methodology involving ABAQUS modeling, Python scripting, and optimization using the Pointer algorithm in Isight, this research adeptly navigates the trade-off, significantly contributing to the advancement of railway transportation systems.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

References

Bracciali A, Megna G. Inside frame bogies & air wheelset : a winning marriage. Proceedings of the 10th International Conference on Railway Bogies and Running Gears “Bogie ’16”; 2016 Sep 12-15; Budapest, Hungary. p. 12-15.

Bracciali A. Railway wheelsets: history, research and developments. Int J Railw Technol. 2016;5(1):23-52.

Carruthers JJ, Calomfirescu M, Ghys P, Prockat J. The application of a systematic approach to material selection for the lightweighting of metro vehicles. Proc Inst Mech Eng Part F J Rail Rapid Transit. 2009;223(5):427-437.

Johnson MS, Evans R, Mistry PJ, Li S, Bruni S, Bernasconi A, et al. Structural analysis for the design of a lightweight composite railway axle. Compos Struct. 2022;290:115544.

Mistry PJ, Johnson MS, Li S, Bruni S, Bernasconi A. Parametric sizing study for the design of a lightweight composite railway axle. Compos Struct. 2021;267:113851.

Wu SC, Liu YX, Li CH, Kang GZ, Liang SL. On the fatigue performance and residual life of intercity railway axles with inside axle boxes. Eng Fract Mech. 2018;197:176-191.

Dassault Systèmes Simulia Corp. Isight 4.0 getting started guide. United States: Dassault Systèmes; 2009.

Abaqus. Abaqus analysis user’s manual. Vol. 5. United States: Abaqus; 2013.

European Committee for Standardization. BS EN 13260:2020: Railway applications, wheelsets and bogies, wheelsets, product requirements. London: BSI; 2020.

der Velden AV, Koch P. Isight design optimization methodologies. United States: Simulia; 2019.

Simulia. Fatigue theory reference. United States: Dassault Systèmes Simulia Corp; 2018.

Simulia. Fe - safe user guide. United States: Dassault Systèmes Simulia Corp; 2020.

European Committee for Standardization. BS EN 13104:2009+A2:2012: Railway applications, wheelsets and bogies, powered axles, design method. London: BSI; 2012.

European Committee for Standardization. BS EN 13103-1:2017: Railway applications - wheelsets and bogies - part 1: design method for axles with external journals. London: BSI; 2011.

British Standards. BSI 8535:2011: Railway applications – wheelsets and bogies – powered and non-powered axles with inboard bearings – Design method. London: BSI; 2011.