Static Bending Test of a Carbon Fiber Posterior Leaf Spring Ankle Foot Orthoses (PLS-AFOs)

Main Article Content

Abstract

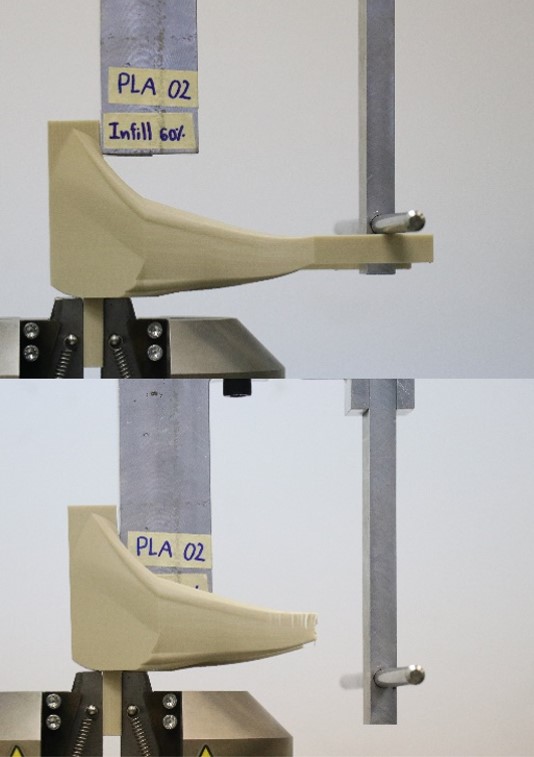

Drop foot is a condition that limits the ability to move the foot upward, which can impair walking. Carbon fiber ankle-foot orthoses (AFOs) are commonly used to assist people with drop foot, but they can be expensive and difficult to obtain. This study investigated the use of 3D printing to create carbon fiber posterior leaf spring AFOs (PLS-AFOs). The foot part or Heel support component of PLS-AFOs were printed using carbon fiber and polylactic acid (PLA) filaments. The strength, weight, and load-displacement relationship of the PLS-AFOs were compared. The results showed that PLS-AFOs made from carbon fiber were stronger, and had a better load-displacement relationship than those made from PLA. This suggests that 3D printing can be used to create affordable and accessible carbon fiber PLS-AFOs. The findings of this study will be used to design a new generation of PLS-AFOs that are stronger, and more affordable than traditional AFOs, making them more accessible to people with drop foot.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

References

International Committee of the Red Cross. Manufacturing guidelines: ankle-foot orthosis. Geneva: ICRC; 2010.

Khaing MS, Samala M, Guerra G, Wisessint A. Design and mechanical testing of an adjustable posterior leaf spring ankle-foot orthosis for patients with drop foot. Prothet Orthot Int. 2024;48(1):39-45.

Jin Y, He Y, Shih A. Process planning for the fuse deposition modeling of ankle-foot-orthoses. Procedia CIRP. 2016;42:760-765.

Hollaway LC. Key issues in the use of fibre reinforced polymer (FRP) composites in the rehabilitation and retrofitting of concrete structures. In: Karbhari VM, Lee LS, editors. Service Life Estimation and Extension of Civil Engineering Structures. Cambridge: Woodhead Publishing; 2011. p. 3-74.

Gregor-Svetec D. Polymers in printing filaments. In: Izdebska-Podsiadły J, editor. Polymers for 3D Printing. Oxford: William Andrew; 2022. p. 155-269.

Gao F, Bedard GG. Effects of materials, reinforcement, and heat treatment on thermoplastic solid ankle-foot orthosis mechanical properties. J Prosthet Orthot. 2013;25(3):143-150.

Ansari AA, Kamil M. Effect of print speed and extrusion temperature on properties of 3D printed PLA using fused deposition modeling process. Mater Today Proc. 2021;45:5462-5468.

Makarian K, Taghvaei M, Tu J, Alvarez NJ, Palmese GR. Design, manufacturing, and elastic analysis of digital light processing 3D printed fiber reinforced sandwich beams with thermosetting polymer matrix. Compos Struct. 2023;318:117108.

Ali MH, Smagulov Z, Otepbergenov T. Finite element analysis of the CFRP-based 3D printed ankle-foot orthosis. Procedia Comput Sci. 2021;179:55-62.

Popescu D, Zapciu A, Amza C, Baciu F, Marinescu R. FDM process parameters influence over the mechanical properties of polymer specimens. Polym Test. 2018;69:157-166.

Krivic G, Slavič J. Simultaneous non-contact identification of the elastic modulus, damping and coefficient of thermal expansion in 3D-printed structures. Polym Test. 2023;125:108131.