Comparison of Disc Brake Squeal between Ordinary and Drilled Brake Discs Using Finite Element Method

Main Article Content

Abstract

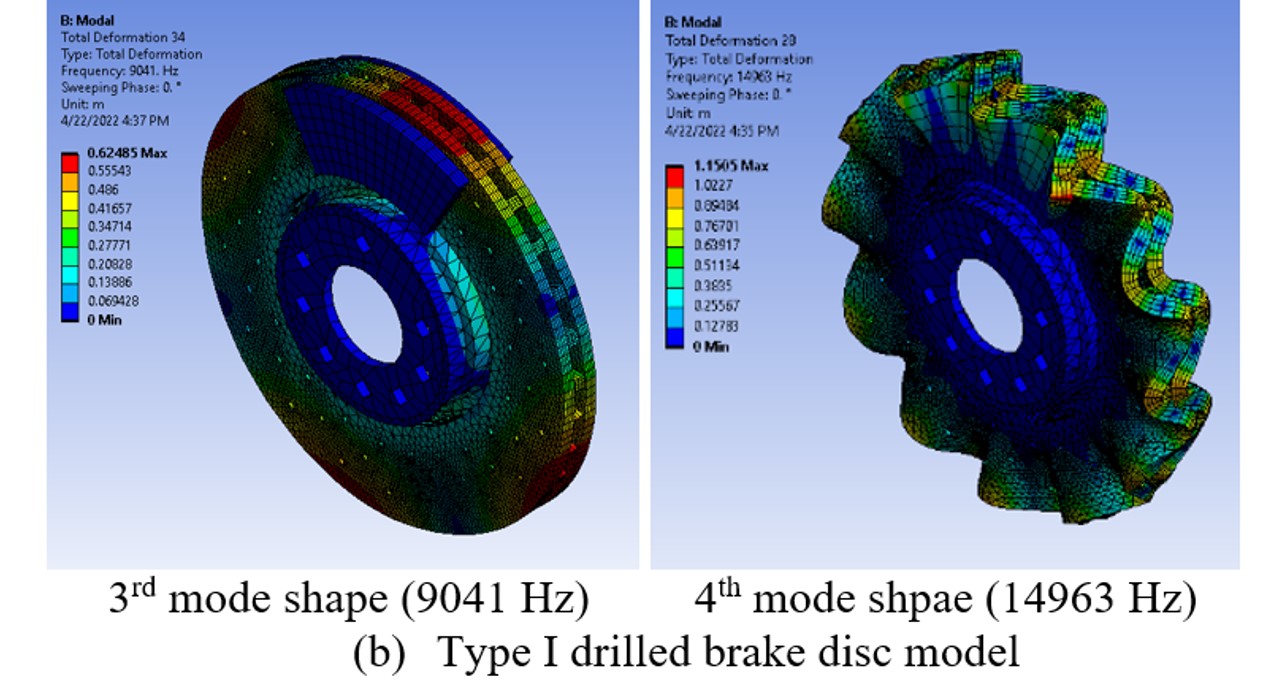

During the braking of the automobile, the brake squeal is a direct concern for the driver. Sometimes, the automaker loses revenue from the customer's warranty claims. The automaker needs to solve or alleviate the squealing noise during the brake action. The study aimed to compare the disc brake squeal of general and drilled brake discs. The disc brake squeal is an instability of the disc brake system. One popular theory used in the analysis is Complex Eigenvalue Analysis and simulation using Finite Element Technique. In this work, three models of brake discs were compared: an ordinary brake disc and two drilled brake discs. For drilled brake discs, the first and second models had 30 and 60 holes on the disc, respectively. The study revealed that a more stiffness structure generates higher frequencies than a flexible structure. Each model generated a different amount of unstable frequency modes.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

References

Hu S, Liu Y. Disc brake vibration model based on stribeck effect and its characteristics under different braking conditions. Math Probl Eng. 2017;2017:6023809.

Belhocine A, Ghazaly NM. Effects of young's modulus on disc brake squeal using finite element analysis. Int J Acoust Vib. 2016;21(3):292-300.

Musil M, Suchal A, Úradníček J, Kraus P. The complex eigenvalue analysis of brake squeal using finite element method. 22nd International Conference Engineering Mechanics; 2016 May 9-12; Svratka, Czech Republic. p. 437-440.

Savant RD, Gajjal SY. Finite element modelling and analysis of brake squeal. Int J Res Sci Innov 2014;I(VIII): 363-369.

Wu Y. Mechanism analysis of a low-frequency disc brake squeal based on an energy feed-in method for a dual coupling subsystem. Shock Vib. 2020;2020:8887529.

Gu Y, Liu Y, Lu C, Hu S, Song X. Effect of compressive strain of brake pads on brake noise. Shock Vib. 2020;2020:8832363.

Kinkaid NM, O'Reilly OM, Papadopoulos P. Automotive disc brake squeal. J Sound Vib. 2003;267(1):105-166.

Filip P, Weiss Z, Rafaja D. On friction layer formation in polymer matrix composite materials for brake applications. Wear. 2002;252(3-4):189-198.

Hassan MZ, Brooks P, Barton D. Thermo-mechanical contact analysis of car disc brake squeal. SAE Int J Passeng Cars - Mech Syst. 2009;1(1):1230-1239.

Ouyang H, Nack W, Yuan Y, Chen F. Numerical analysis of automotive disc brake squeal: a review. Int J Veh Noise Vib. 2005;1(3-4):207-231.

Xie MS, Zhang GR, Li JH, Fritsch R. Brake pad taper wear on brake moan noise. Int J Automot Technol. 2014;15(4):565-571.

Lü H, Yu D. Brake squeal reduction of vehicle disc brake system with interval parameters by uncertain optimization. J Sound Vib. 2014;333(26):7313-7325.

Benaroya H, Nagurka M, Han S. Mechanical vibration: analysis, uncertainties, and control. 4th ed. London: CRC Press; 2017.

Brembo. Brake disc 09.9177.10 [Internet]. Bergamo: Brembo S.p.A.; 2022 [cited 2022 Jan 25]. Available from: https://www.bremboparts.com/asiapacific/en/catalogue/disc/09-9177-10.

FEA Tips. How to verify mesh quality in ansys workbench [Internet]. 2022 [cited 2022 Jan 25]. Available from: https://featips.com/2021/05/07/how-to-verify-mesh-quality-in-ansys-workbench/.

FEA Tips. Lecture 7: Mesh quality & advance topics (introduction to ansys meshing) [Internet]. Ansys inc; 2015 [cited 2022 Jan 25]. Available from: https://featips.com/wp-content/uploads/2021/05/Mesh-Intro_16.0 _L07_Mesh_Quality_and_Advanced_Topics.pdf.