Experimental Investigation of Optimal Pressure Achieved through Rubber Foam Extension in the Curing Process

Main Article Content

Abstract

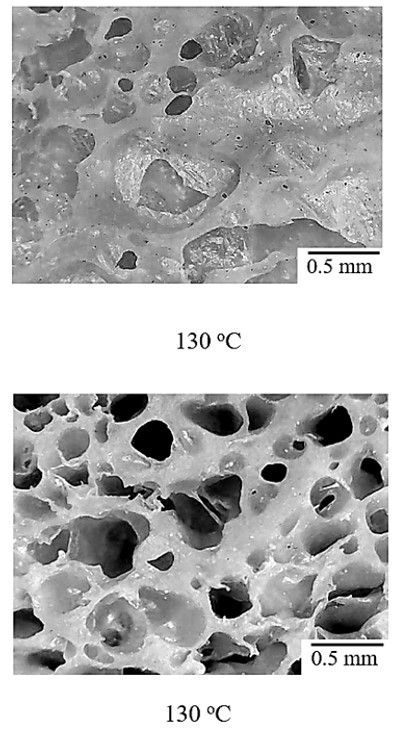

The aim is to determine the optimal expansion pressure of the rubber foam in the mold to determine the curing time that ensures good mechanical properties. In the experiment, the temperature was examined in three levels: 130, 140, and 150°C, for 20 min. Additionally, 8 compounds were examined with either DPT or ADC blowing agents. The experiment results indicated that the compressive stress and absorbed energy showed a similar trend, which was directly changed by both temperature and blowing agent. The appropriate compounds were compound 4 with 12 phr ADC and compound 5 with 3 phr DPT with the optimal pressure of 0.22 bar and 0.17 bar, respectively. Both ensured the high absorbed energy and high compression set. By determining the optimal internal pressure, the energy consumption of the NR foaming process can be calculated. In addition, the energy consumption was significantly changed by the area ratio.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

References

Rostami-Tapeh-Esmaeil E, Rodrigue D. Morphological, mechanical and thermal properties of rubber foams: a review based on recent investigations. Materials. 2023;16(5):1934.

Rostami-Tapeh-Esmaeil E, Vahidifar A, Esmizadeh E, Rodrigue D. Chemistry, processing, properties, and applications of rubber foams. Polymers. 2021;13(10):1565.

Pechuraia W, Muansupan T, Seawlee P. Effect of foaming temperature and blowing agent content on cure characteristics, mechanical and morphological properties of natural rubber foams. Adv Mater Res. 2014;844:454-457.

Oliveira-Salmazo L, Lopez-Gil A, Silva-Bellucci F, Job AE, Rodriguez-Perez MA. Natural rubber foams with anisotropic cellular structures: mechanical properties and modeling. Ind Crops Prod. 2016;80:26-35.

Zhang X, Zhang J, Cheng Z. Application of response surface methodology to optimize the preparation of rubber foam composite as sound-absorbing material using scrap rubber powder. J Wuhan Univ Technol Mat Sci Edit. 2019;34:1376-1383.

Petdee T, Naemsai T, Pianhanuruk E, Boonchouytan W, Homkhiew C. Effects of blowing agents and curing temperatures on physical and mechanical properties of natural rubber foam for laminated floor tiles. Polym Polym Compos. 2022;30:1-12.

Berger T, Kaliske M. A thermo-mechanical material model for rubber curing and tire manufacturing simulation. Comput Mech. 2020;66:513-535.

Lin L, Zheng Z, Li X, Park S, Zhang W, Diao G, et al. Design strategy for porous carbon nanomaterials from rational utilization of natural rubber latex foam scraps. Ind Crops Prod. 2023;192:116036.

ASTM. ASTM D395-03: Standard test methods for rubber property—compression set (Test method B). West Conshohocken: ASTM international; 2002.

ASTM. ASTM D3575-00: Standard test methods for flexible cellular materials made from olefin polymers. West Conshohocken: ASTM International; 2000.

ASTM. ASTM D575-91: Standard test methods for rubber properties in compression. West Conshohocken: ASTM international; 2001.

Thinakul N. NRI-TS500-50 Universal Mechanical Testing Machine [Internet]. 2020 [cited 2023 Apr 24]. Available from: http://www.narin.co.th/NRI-TS/NRI-TS500-50.html. (In Thai)

Zhai W, Jiang J, Park CB. A review on physical foaming of thermoplastic and vulcanized elastomers. Polym Rev. 2022;62(1):95-141.