Evaluation for Optimal Configuration of Twisted Fiber Bundle Wick Heat Pipe with Top Heat Mode

Main Article Content

Abstract

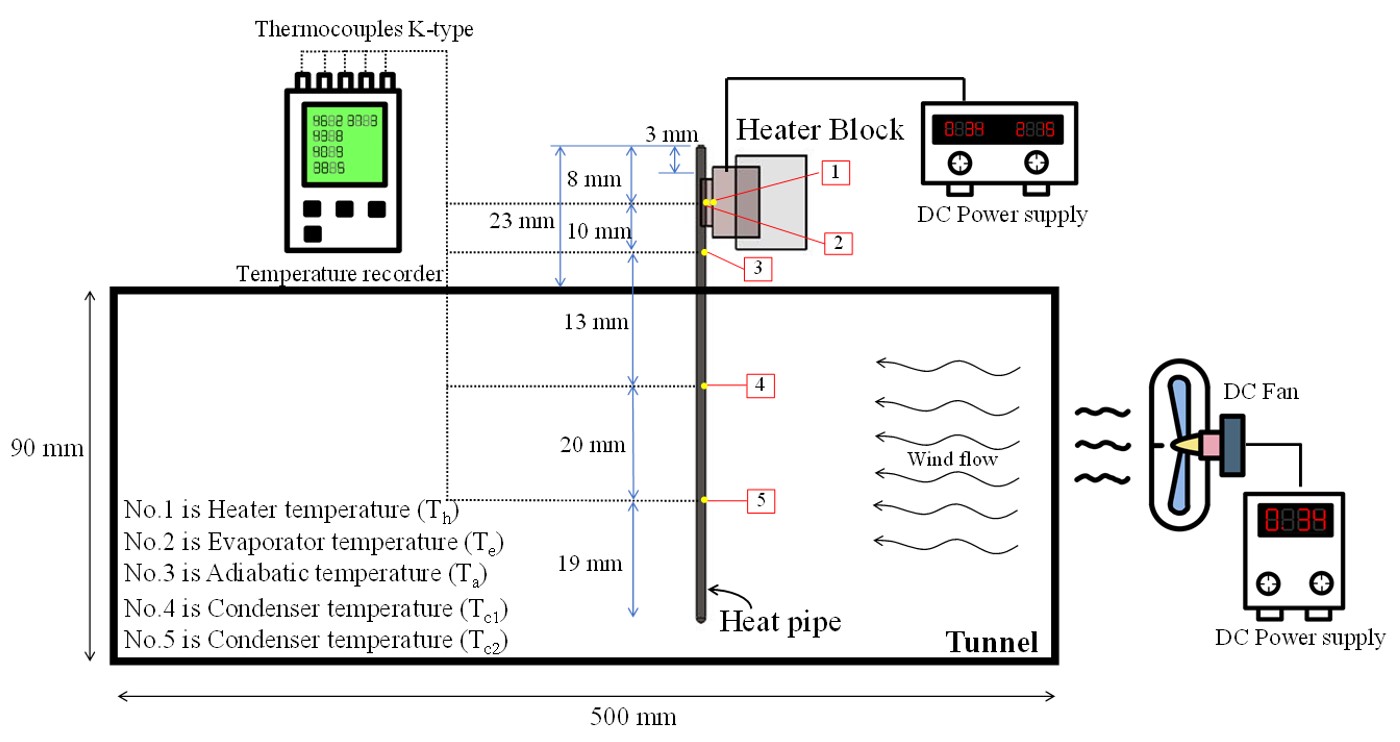

The objective of this research was investigating the thermal resistance of the twisted fiber bundle wick (TFBW) heat pipe. TFBW was made by combining between both size copper fiber of 30 μm and 50 μm. These were arranged as the lengthwise and twist together. The variable parameters of the TFBW were focused on the mixing ratio and twisting pitch length. TFBW heat pipe with outer diameter of 3 mm and length of 70 mm was heated in the top heat mode. Heat input was maintained as constant value at the evaporator section. The condenser section was cooled by air. The outer surface of both sections was measured temperature which were using for calculating the thermal resistance. It was observed that the mixing ratio of 50%:50% demonstrated the lowest thermal resistance for twist pitches of 10 mm and 15 mm. Due to the appropriate pore size of the formed wick, it provided high capillary pressure and high permeability. The decreasing of twist pitch (tighter twisting) caused to increasing of thermal resistance. This was because an excessive twist resulted in very small pore sizes led to lower permeability. The mixing ratio of 50%:50% with a pitch length of 20 mm exhibited an opposite trend because that already had the appropriate pore size. Moreover, the twisting with a smaller pitch had smaller pores leading to a higher capillary pressure. Therefore, the optimal configuration of TFBW providing the lowest thermal resistance was the mixing ratio of 50%:50% with a pitch length of 10 mm.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

References

Hota SK, Lee KL, Leitherer B, Elias G, Hoeschele G, Rokkam S. Pulsating heat pipe and embedded heat pipe heat spreaders for modular electronics cooling. Case Stud Therm Eng. 2023;49:1-14.

Dobre T, Parvulescu OC, Stoica A, Iavorschi G. Characterization of cooling systems based on heat pipe principle to control operation temperature of high-tech electronic components. Appl Therm Eng. 2010;30(16):2435-2441.

Reay DA, Kew AP, McGlen RJ. Heat pipe. 6th ed. Oxford: Elsevier; 2014.

Kawahara Y, Mochizuki M, Saito Y, Horiuchi Y, Ahamed M. One-millimeter heat pipe and application to cooling module for electronic devices. Fujikura Tech Rev. 2011;40:34-38.

Lin YJ, Hwang KS. Effect of particle size and particle size distribution on heat dissipation of heat pipes with sintered porous wicks. Metall Mater Trans A. 2009;40(9):2071-2078.

Mochizuki M, Saito Y, Nguyen T, Mashiko K, Kumthonkittkun V, Kuriyama H, et al. The development of composite wick heat pipe. 1st International seminar on heat pipe and heat recovery system; 2004 Dec 8-9; Kuala Lumpur, Malaysia. p. 158-163.

Sauciuc I, Mochizuki M, Mashiko K, Saito Y, Nguyen T. The design and testing of the super fiber heat pipes for electronics cooling applications. Sixteenth Annual IEEE Semiconductor Thermal Measurement and Management Symposium; 2000 Mar 23; San Jose, USA. USA: IEEE; 2000. p. 27-32.

De Schampheleire S, De Kerpel K, Deruyter T, De Jaeger P, De Paepe M. Experimental study of small diameter fibres as wick material for capillary-driven heat pipes. Appl Therm Eng. 2015;78:258-267.

Grason GM. Geometry and optimal packing of twisted columns and filaments. Rev Mod Phys. 2015;87(2):401-419.

Loh CK, Harris E, Chou DJ. Comparative study of heat pipes performances in different orientations. Semiconductor Thermal Measurement and Management IEEE Twenty First Annual IEEE Symposium; 2005 Mar 15-17; San Jose, USA. USA: IEEE; 2005. p. 191-195.

Xiang J, Chen XB, Huang J, Zhang C, Zhou C, Zheng H. Thermal performances of anti-gravity heat pipe with tapering phase-change chamber. Energies, 2020;13(19):1-10.

Mueller GE. Numerical packing spheres in cylindrical. Powder Technol. 2005;159(2):105-110.

Mueller GE. Numerical simulation of packed beds with monosized spheres in cylindrical containers. Powder Technol.1997;92(2):179-183.

Thuchayapong N. Void fraction simulation of sintered wicks used in heat pipe [thesis]. Chiang Mai: Chiang Mai University; 2008.