Redesign of the Mini Hydro Turbine Structure Using Finite Element Analysis (FEA) to Solve Resonance Problem

Main Article Content

Abstract

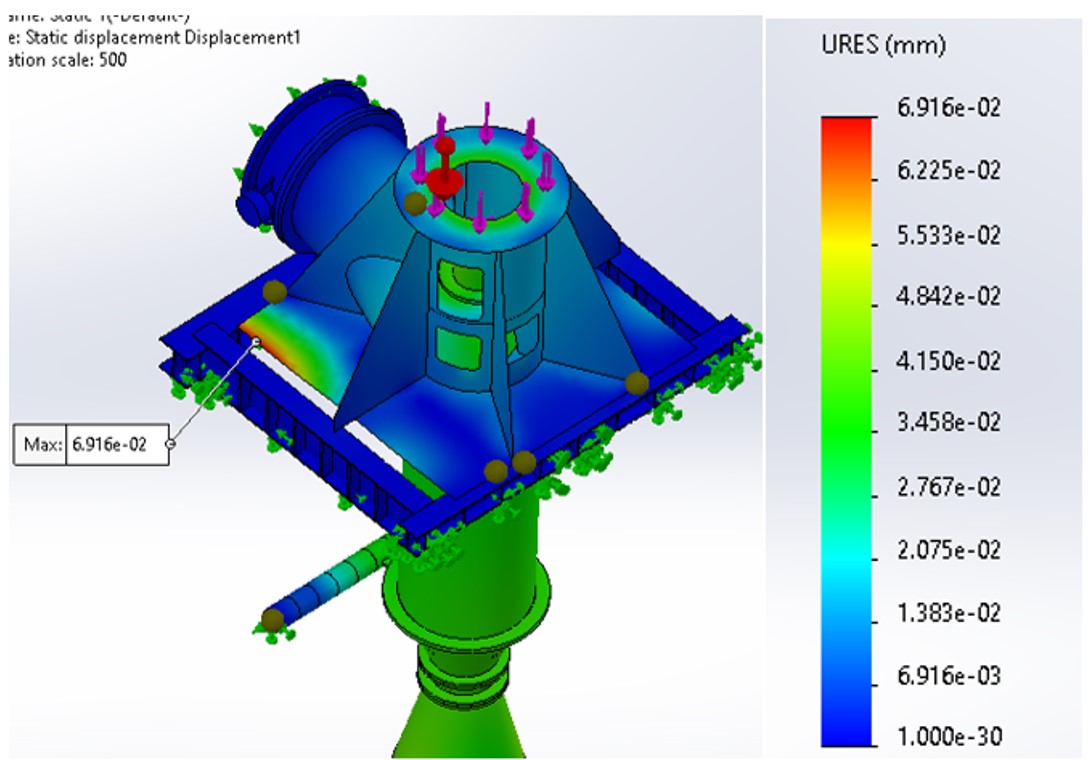

This study investigates the structural redesign of a mini hydro turbine system in an effort to solve the turbine shaft resonance problem. The original design of the turbine shaft support is examined to identify the root causes of the problem, which result in the failure of the turbine bearings. In order to approximate the natural frequencies, finite element analysis (FEA) models are developed and verified through comparison with experimental data, which may consist of modal analysis, coast-down testing, and deflection tests. Experimental results deviate from the FEA analysis of mode 1 frequency by 6.81%. Analysis of the linear dynamic response reveals that the amplitude of the shaft coupling's vibrations during system start-up and shutdown exceeds the allowable design parameters; this is the primary cause of bearing damage. FEA is used to redesign the shaft structural support in order to eliminate the natural frequencies. Modes 1 and 2 exhibit frequency shifts of 14.57 to 38.16 Hz and 11.36 to 37.57 Hz, respectively. These values are double the frequency at which a typical generator operates. The maximum shaft support deflection is reduced from 0.25–0.39 mm to 0.01 mm, according to the FEA results. Utilizing the redesign parameters, a new shaft support will be constructed. To confirm the FEA results, it is possible to monitor and recheck the data.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

References

Hydro power plant part maintenance and manufacturing section EGAT. Installation Maintenance and commissioning of EGAT irrigation Lam-rang Mini hydro power plant. Nonthaburi: EGAT; 2016.

Finley WR, Sauer BJ, Loutfi M. Motor vibration problems: how to diagnose and correct vibration errors. IEEE Ind Appl Mag. 2015;21(6):14-28.

Queen R, Chatlos G. Coast-downs and run-ups: understanding vibration responses. 2018 IEEE Petroleum and Chemical Industry Technical Conference (PCIC); 2018 Sep 24-26; Cincinnati, USA. USA: IEEE; 2018. p. 289-96.

Mohamad Faizul Aslam MI. A study of correlation between finite element analysis and experimental modal analysis in structural dynamic analysis. Pahang: Faculty of Mechanical Engineering, University Malaysia Pahang (UMP); 2018.

Srinivas K. Verifications and validations in finite element analysis (FEA). Ahmedabad: Advanced Scientific and Engineering Services (AdvanSES); 2020.

Gautam A. Structural analysis of Kaplan turbine shaft using ANSYS. Haryana: Department of Mechanical Engineering, National Institute of Technology Kurukshetra; 2013.

El-Shaikh SAA. Experimental investigation and finite element analysis for solving vertical pumps structural weakness. Eur J Mech Eng Res. 2016;3(2):50-63.

Thongsiri G. Mechanical vibration of water turbine in Sirikit hydro power plant unit. Chiang Mai: Department of Mechanical Engineering, Faculty of Engineering, Chiang Mai University; 2012.

Gustavsson R, Nässelqvist M, Österud J. Radial dampers impact on shaft vibration at resonance. IOP Conf Ser: Earth Environ Sci. 2019;240:022011.

Valentín D, Presas A, Egusquiza E, Valero C, Bossio M. Dynamic response of the MICA runner. Experiment and simulation. J Phys: Conf Ser. 2017;813:012036.

Xie J, Huang B, Fu L. Reinforcement and resonance control of head cover of Francis turbine by finite element analysis and modal testing. IOP Conf Ser: Earth Environ Sci. 2020;560:012051.

Promwungkwa A. ME422: Introduction to finite element method. Department of Mechanical Engineering, Faculty of Engineering, Chiang Mai University; 2021.

Allemang RJ, Brown DL. Chapter 21 Experimental modal analysis. In: Piersol AG, Paez TL, editor. Harris’ Shock and Vibration Handbook. 6th ed. NewYork: McGraw-Hill; 2010. p. 21.

Bliss Services Thailand. Modal analysis Me’scope training for EGAT 2022. Nonthaburi: EGAT; 2022.

Eisenmann Sr RC, Eisenmann Jr RC. Machinery malfunction diagnosis and correction. Menlo Park: Hewlett-Packard effective; 2005.

Wilcox Ed. Vibration analysis for turbomachinery. The 45th Turbomachinery and the 32nd Pump symposia; 2016 Sep 12-15; Houston, USA. p. 1-50.

Loeser S, Neto MM. Design methodology for vertical centrifugal pumps. 2011 International Nuclear Atlantic Conference – INAC2011; 2011 Oct 24-28; Belo Horizonte, Brazil. p. 1-10.

El-Gazzar DM. Finite element analysis for structural modification and control resonance of a vertical pump. Alexandria Eng J. 2017;56(4):695-707.