Effect of Injection Frequency on Actual Fuel Injection Rate of Piezoelectric Diesel Fuel Injector

Main Article Content

Abstract

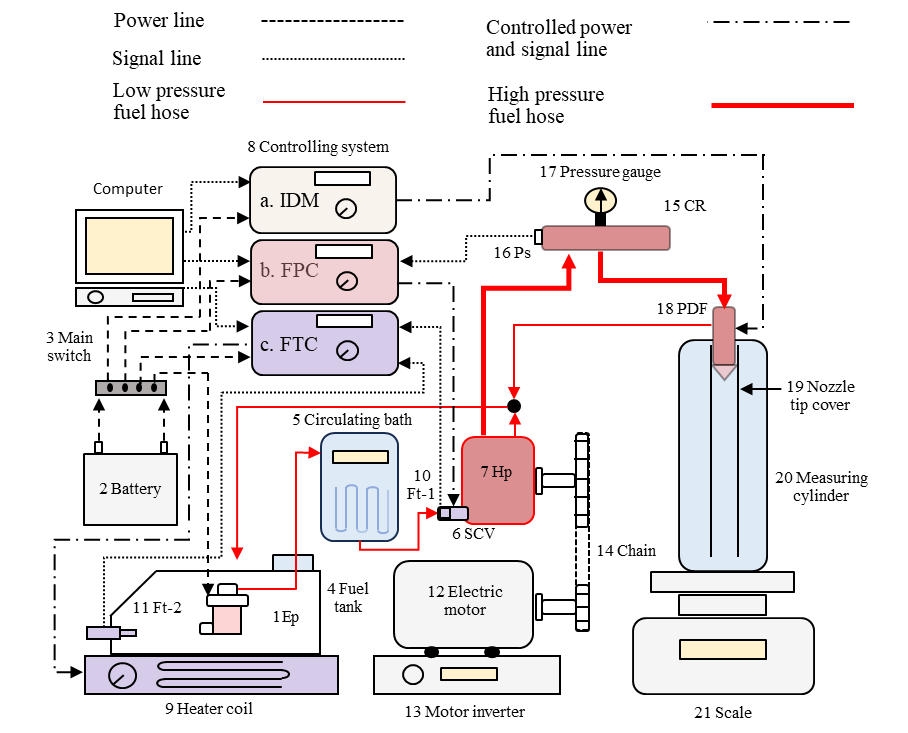

The objectives of this research was to investigate the effect of injection frequencies (IF) on the actual fuel injection rate (Act.FI) and discrepancy between Act.FI and ideal fuel injection rate (Ideal.FI) of a piezoelectric diesel fuel injector (PDF). IF and duty-times (Dt) of injector control signal (ICS) were varied from 8.33 Hz to 33.33 Hz and 200 μs to 2,000 μs respectively. Moreover, difference pressure (Dp) and fuel temperature (Ft) were varied from 800 bar to 1,600 bar and 25 oC to 45 oC respectively. It was found that when the IF increased, the Act.FI proportionally increased with a higher gradient compared with an increase of the Ideal fuel injection rate (Ideal.FI) at a certain Dt. The minimum Act.FI was shown at lowest IF equaled to 12.9 g/min appearing at Dp and Ft of 800 bar and 45°C. The maximum Act.FI was shown at highest IF equaled to 190 g/min appearing at Dp and Ft of 1,600 bar and 25°C. The discrepancy was directly proportional to the IF which demonstrated the maximum value of 7.7 g/min or equaled to 4.07% compared to Ideal.FI at IF of 33.32 Hz appearing at Dt, Dp and Ft of 2,000 μs, 1,600 bar and 45°C. These were affected by nozzle closure delay which was consequently influenced by the movement of an injector needle. The benefits obtained from this research could be utilized by compensating the Act.FI to be close to the Ideal.FI in the actual operation of a common rail direct injection diesel engines.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

References

Wang X, Ge Y, Yu L, Feng X. Comparison of combustion characteristics and brake thermal efficiency of a heavy-duty diesel engine fueled with diesel and biodiesel at high altitude. Fuel. 2013;107:852-858.

Yu X, Wu B, Su W. Experimental study on the approach for improved brake thermal efficiency on a two-stage turbocharged heavy-duty diesel engine. Fuel. 2021;305:1-11.

Krogerus T, Hyvönen M, Huhtala K. Analysis of common rail pressure signal of dual-fuel large industrial engine for identification of injection duration of pilot diesel injectors. Fuel. 2018;216:1-9.

EL-Seesy AI, Kayatas Z, Takayama R, He Z, Kandasamy S, Kosaka H. Combustion and emission characteristics of RCEM and common rail diesel engine working with diesel fuel and ethanol/hydrous ethanol injected in the intake and exhaust port: assessment and comparison. Energy Convers Manag. 2020;205:1-19.

Choi M, Park S. Optimization of multiple-stage fuel injection and optical analysis of the combustion process in a heavy-duty diesel engine. Fuel Process Technol. 2022;228:1-15.

Hariharan D, Krishnan SR, Srinivasan KK, Sohail A. Multiple injection strategies for reducing HC and CO emissions in diesel-methane dual-fuel low temperature combustion. Fuel. 2021;305:1-11.

Mata C, Rojas-Reinoso V, Soriano JA. Experimental determination and modeling of fuel rate of injection: a review. Fuel. 2023;343:1-13.

Plamondon E, Seers P. Development of a simplified dynamic model for a piezoelectric injector using multiple injection strategies with biodiesel/diesel-fuel blends. Appl Energy. 2014;131:411-424.

d'Ambrosio S, Ferrari A. Direct versus indirect acting piezoelectric CR injectors: Comparison of hydraulic performance, pollutant emissions, combustion noise, and fuel consumption. SAE Int J Engines. 2018;11(5):585-612.

Han J, Wang S, Vittori RM, Somers LMT. Experimental study of the combustion and emission characteristics of oxygenated fuels on a heavy-duty diesel engine. Fuel. 2020;268:1-15.

Köhler R, Rinderknecht S. A phenomenological approach to temperature dependent piezo stack actuator modelling. Sens Actuator A Phys. 2013;200:123-132.

Taghavifar H, Shervani-Tabar MT, Abbasalizadeh M. Numerical study of the effects of injector needle movement and the nozzle inclination angle on the internal fluid flow and spray structure of a group-hole nozzle layout. Appl Math Model. 2015;39(23-24):7718-7733.

Ferrari A, Mittica A. FEM modeling of the piezoelectric driving system in the design of direct-acting diesel injectors. Appl Energy. 2012;99:471-483.

Parida L, Moharana S. A comprehensive review on piezo impedance based multi sensing technique. Results Eng. 2023;18:1-11.

Satkoski CA, Ruikar NS, Biggs SD, Shaver GM. Piezoelectric fuel injection: cycle-to-cycle control of tightly spaced injections. Control Eng Pract. 2012;20(11):1175-1182.

Sun P, Xu Z, Jin L, Zhu X. A novel piezo inertia actuator utilizing the transverse motion of two parallel leaf-springs. Micromachines. 2023;14(5):1-13.

Hogg T, Stojanovic S, Tebbs A, Samuel S, Durodola J. A benchmark study on the flow metering systems for the characterisation of fuel injectors for future heavy duty commercial vehicles. Measurement. 2020;153:1-9.

Xu L, Bai XS, Jia M, Qian Y, Qiao X, Li X. Experimental and modeling study of liquid fuel injection and combustion in diesel engines with a common rail injection system. Appl Energy. 2018;230:287-304.

d'Ambrosio S, Ferrari A. Diesel engines equipped with piezoelectric and solenoid injectors: hydraulic performance of the injectors and comparison of the emissions, noise and fuel consumption. Appl Energy. 2018;211:1324-1342.

Bae G, Choi S, Lee S, Moon S, Wang J, Kim K, et al. Experimental investigation of fuel temperature effects on transient needle motion and injection velocity of solenoid type diesel injector. Int J Heat Mass Transf. 2021;181:1-9.

Viera JP, Payri R, Swantek AB, Duke DJ, Sovis N, Kastengren AL, et al. Linking instantaneous rate of injection to X-ray needle lift measurements for a direct-acting piezoelectric injector. Energy Convers Manag. 2016;112:350-358.

Kammuang-lue N, Bhudtiyatanee M. Optimum ratio of compressed biomethane gas as dual fuel in turbocharged common rail diesel engine. J Energy Inst. 2018;91(6):1113-1125.

Nguyen VH, Cavicchi A, Nguyen DX, Nguyen KT, Pham PX, Postrioti L. Hydraulic characterization of a second-generation common rail injector operating under solo and split injection strategies. Flow Meas Instrum. 2022;85:1-14.

Mehlfeldt D, Weckenmann H, Stöhr G. Modeling of piezoelectrically actuated fuel injectors. Mechatronic. 2008;18(5-6):264-272.

Luo F, Sun Y, Moro A, Jin T, Wang C. Measurement and analysis of injection characteristics among each nozzle hole within a heavy-duty diesel engine. Flow Meas Instrum. 2021;79:1-10.

Coppo M, Dongiovanni C, Negri C. A linear optical sensor for measuring needle displacement in common-rail diesel injectors. Sens Actuator A Phys. 2007;134(2):366-373.