Development of Ultra-Low Temperature Cooling System Based on Peltier Module

Main Article Content

Abstract

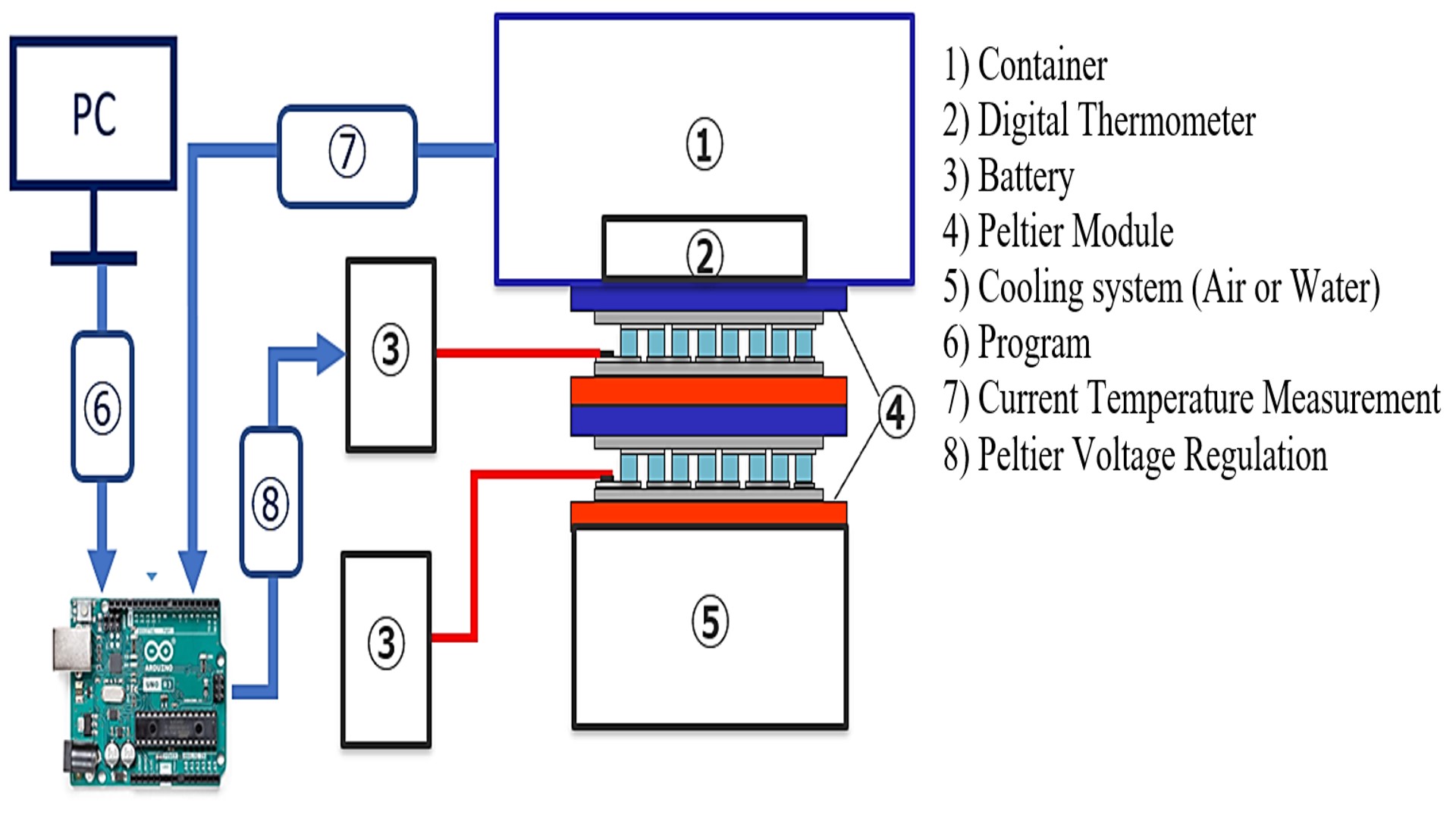

In recent years, with the development of medical methods utilizing genes and cells, the requirement for low-temperature transportation (cold chain) has increased. Also, to transport the corona vaccine, a low temperature environment up to -80℃ is demanded. Nowadays, the commonly used cooling method is the compressor type applied to refrigerators and air conditioners, but they are not suitable for portable transportation. In thermoelectric cooling, Peltier modules, as components applicable to cooling, are very suitable for building cooling systems due to their simple structure, light weight, low noise and most importantly, no refrigerant is required. In this study, a cooling system has been developed based on Peltier modules instead of using the traditional compressor to obtain an environmentally friendly ultra-low temperature environment. The purpose of this research is to fabricate the cooling device that can reach -30℃. In this study, firstly, the calculation has been performed to select the suitable Peltier module. Secondly, a cooling device experimental system was established. Finally, the cooling experiments of was carried out. As a result of the experimentations, in the case of water cooling, it can be confirmed that the minimum temperature of the cooling device could reach -38° C.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

References

Sittiarttakorn V, Boonto S. Temperature control and stabilization of an industrial oven using thermoelectric devices as the stabilize actuator. J Jpn Soc Appl Electromagn Mech. 2019;27(3):366-370.

Murasawa C, Kosugi T. Performance evaluation of Peltier cooler focusing on power consumption. Proceedings of Mechanical Engineering Congress; 2017 Sep 3-6; Saitama, Japan. p. 1-5. (In Japanese)

Zhu N, Koshimizu S, Nozaki T, Taneishi K, Otsuka J, Shirai T, et al. Decrease of thermal expansion of ball screw used for precision positioning device by Peltier module cooling based on feedback method. Int J Autom Technol. 2013;7(5):564-570.

Remeli MF, Bakaruddin NE, Shawal S, Husin H, Othman MF, Singh B. Experimental study of a mini cooler by using Peltier thermoelectric cell. IOP Conf Ser: Mater Sci Eng. 2020;788:012076.

Guras R, Mahdal M. Use of Peltier modules for liquid cooling. 22nd International Carpathian Control Conference (ICCC); 2021 Jun 1 – May 31; Velké Karlovice, Czech Republic. USA: IEEE; 2021. p. 1-4.

Posobkiewicz K, Gorecki K. Influence of selected factors on parameters of a cooling system with a Peltier module and forced air flow. Microelectron Int. 2022;39(4):141-146.

Schmidt R, Brouwer PW. Theory of the low-temperature longitudinal spin Seebeck effect. Phys Rev B. 2021;103:014412.

Fukuda K. Practical use of Peltier modules. J Heat Transf Soc of Jpn. 2005;44(186):18-21. (In Japanese)

He H, Shen L, Chen H, Zhang X, Tu Z. Impact of driving power on refrigeration performance of thermoelectric modules. Refrig Technol. 2018;(2):1-5. (In Chinese)

Tasawa I. Design and manufacture of high accuracy temperature control and comparison calibration system by thermoelectric cooling tank using Peltier device. Japan: TAZAWA R&D Co., Ltd; 2007. (In Japanese)

A Zelazna, J Golebiowska. Life cycle assessment of cooling and heating system based on Peltier module. IOP Conf Ser: Earth Environ Sci. 2019;290:012067.