The design and analysis of the screw conveyor blade for the small rice milling machine

Main Article Content

Abstract

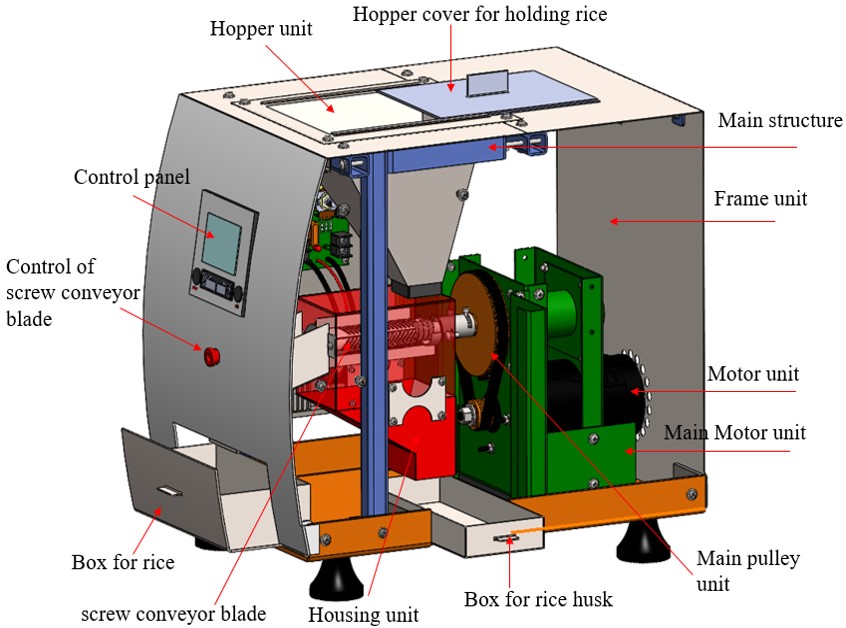

The objective of this study was to design and analyze a screw conveyor blade for a small rice milling machine using Finite Element Analysis. The machine consists of a hopper with a cover, housing, the main structure support and a power transmission unit. The geometry of the machine was developed using Autodesk Inventor software. The model analysis for Finite Element Analysis was analyzed using Stress Analysis. Appropriate materials were selected for the components and design analysis was carried out. The maximum Von Mises stresses on the screw conveyor for the galvanized steel and stainless-steel materials were 1.649 and 1.645 MPa, respectively, and the maximum value of total deformation was 0.001998 and 0.001993 mm when a force of 9 N was applied to the screw conveyor and the main support of the structure. The result of FEA prediction leads to the comparison of the results of the analytical and experimental model.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

References

Ruekkasaem, L. and Sasananan, M. Optimal parameter design of rice milling machine using design of experiment, Materials Science Forum, Vol. 911, 2017, pp. 107-111.

Zareiforoush, H., Minaei, S., Alizadeh, MR., Banakar, A. and Samani, B.H. Design, development and performance evaluation of an automatic control system for rice whitening machine based on computer vision and fuzzy logic, Computers and Electronics in Agriculture, Vol. 124, 2016, pp. 14-22.

Khatri, S. Performance evaluation of Chinese mini combine rice mill cum grind machine, International Journal of Engineering Research and General Science, Vol. 8(4), 2020, pp. 22-34.

Caringal, B.K.M., Dela Rosa, Z.S., Maan, K.V.R. and Camello N.C. Design and development of rice milling and grinding machine, EPH-International Journal of Science and Engineering, Vol. 2(8), 2016, pp. 6-14.

Adegun, I.K., Adepoju, S.A. and Aweda, J.A. A mini rice processing machine for Nigerian farmers, Journal of Agricultural Technology, Vol. 8(4), 2012, pp. 1207-1216.

Khaeso, K., Meekhao, A., Junsiri, C., Sudajan1, S. and Laloon, K. Study and development of small brown rice milling machine for household, Agricultural Science Journal, Vol. 49(S4), 2018, pp. 263-266.

Dhankhar, P. Rice milling, IOSR Journal of Engineering (IOSRJEN), Vol. 4(5), 2014, pp. 34-42.

Odior, A.O. and Oyawale, F.A. Application of time study model in rice milling firm: A case study, Journal of Applied Science and Environmental Management, Vol. 15(3), 2011, pp. 501-505.

Adedeji, K.A., Raji, N.A., Oyetunji, E.O. and Ishola, B. Design and fabrication of a motorized rice hulling machine, Journal of Engineering Research, Vol. 11(1), 2020, pp. 1-10.

Xiangyi, M., Yanlong, H., Fuguo, J., Peiyu, C., Yawen, X., Shigang, B. and Hongwei, Z. Numerical simulation approach to predict the abrasion rate of rice during milling, Biosystems Engineering, Vol. 206, 2021, pp. 175-187.

Anqi, L., Yanlong, H., Fuguo, J., Jincheng, Z., Xiangyi, M., Peiyu, C., Yawen, X. and Hongwei, Z. Examination milling non-uniformity in friction rice mills using by discrete element method and experiment, Biosystems Engineering, Vol. 211, 2021, pp. 247-259.

Rattanawong, K., Fakthong, M., Chuenchomnakjad, S., Chaoumead, A., Chumnumwat, S. and Peopayom, S. The development of a household rice milling machine, Journal of Innovation Technology Research, Vol. 4(1), 2020, pp. 40-46.

Oko, C.O.C, Diemuodeke, E.O. and Akilande, I.S. Design of hoppers using Spreadsheet, Research in Agricultural Engineering, Vol. 56, 2010, pp. 53-58.

Osore, O.A. and Adio, M.A. Design and development of an Ofada rice hulling machine, International Research Journal of Engineering and Technology (IRJET), Vol. 5(11), 2018, pp. 284-291.

Osoro, O.A. and Adio, M.A. Design and development of an Ofada rice hulling machine, International Research Journal of Engineering and Technology, Vol. 5(11), 2018, pp. 284-291.