Damage of punch/die tools in steel wire rod shear cutting

Main Article Content

Abstract

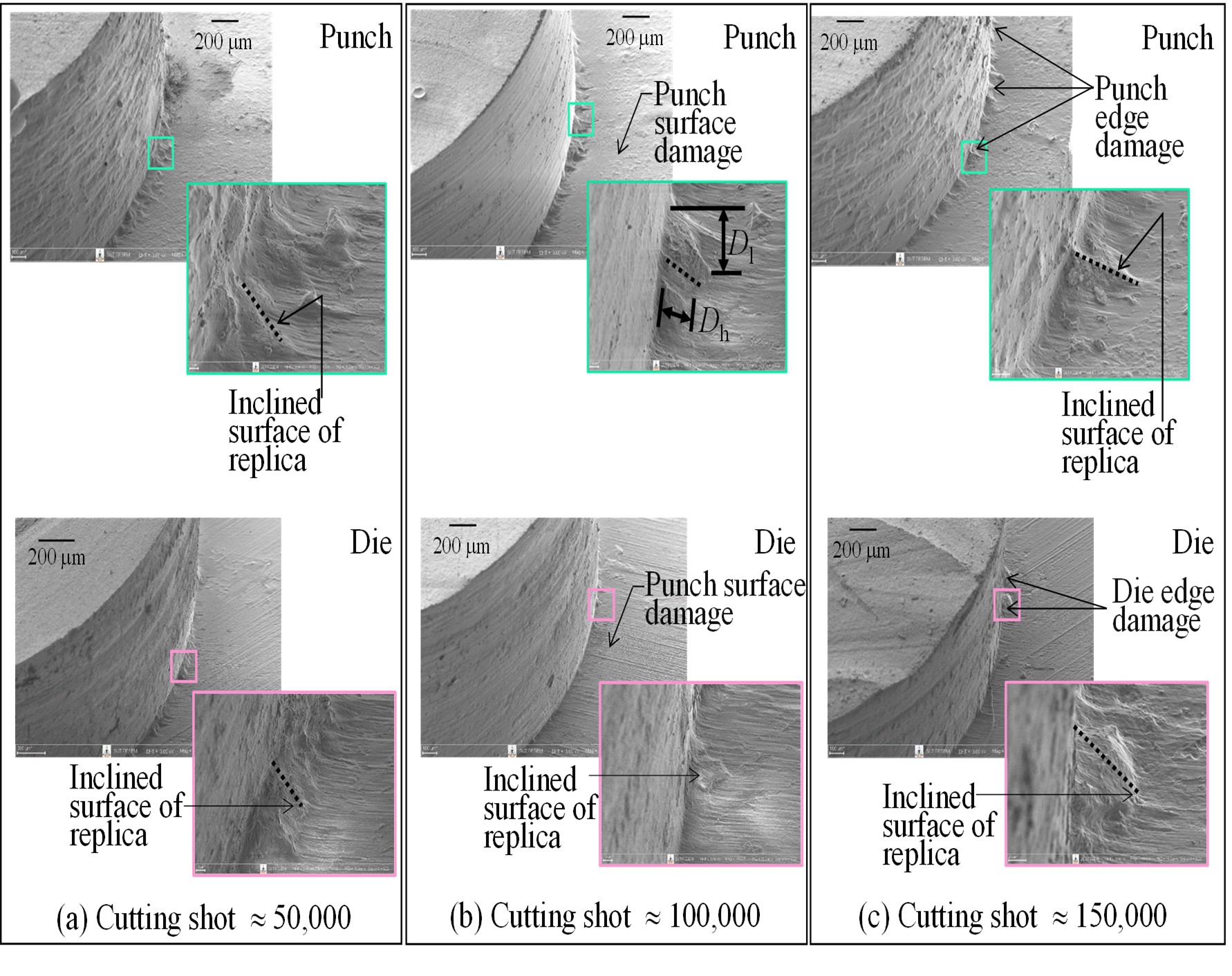

In this research work, damage of punch/die tools in a steel wire rod shear cutting was investigated. The tools (punch and die) used in a steel wire rod (JIS SCM420) cutting ranging from 50,000 to 150,000 cutting shots were collected for the investigation. Experimental results showed that the main damage of the tools at the sheared zone was tool edge chipping. The edge of the die was chipped severely when passing 150,000 cutting shots. To investigate the cutting characteristics of the wire rod by the damaged tools, the tools were applied for a shear cutting test using a developed shear cutting tool holder. It was found that the damage of the tools did not remarkably affect the cutting load resistance of the wire rod. However, when cutting the wire rod with the higher-cutting-shot tools, the quality of the sheared edge deteriorated. Namely, the sizes of the rollover and the burr at the sheared edges of the wire rod tended to increase.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

References

Basily, B.B. and Das, M.K. Factors affecting stress cracking in cold/warm cropping of steel billets, Journal of Mechanical Working Technology, Vol. 2, 1987, pp. 217-239.

Natpukkana, P., Mitsomwang, P., Borrisutthekul, R., Panuwannakorn, R., Khao-phong, L. Effects of cutting parameters on edge features of steel rod cut by punch/die shearing, International Journal of Mechanical and Production Engineering, Vol. 6(5), 2018, pp. 39-45.

Cui, Z., Bhattacharya, S., Green, D.E., Alpas, A.T. Mechanisms of die wear and wear-induced damaged at the trimmed edge of high strength steel sheet, Wear, Vol. 426-427, 2019, pp. 1635-1645.

Sontamino, A. and Ihipprakmas, S. Shearing clearance and shaving allowance to minimize die-roll formation in shaving process, Procedia Engineering, Vol. 29, 2019, pp. 361-368.

Li, H., Wu, X., Li, G., Zhou, D. Chipping damage of die for trimming advanced high-strength steel sheet: evaluation and analysis, Journal of Materials Processing Technology, Vol. 285, 2020, pp. 1-11.

Lee, K.O., Kim, J.M., Chin, M.H., Kang, S.S. A study on the mechanical properties for developing a computer simulation model for heat treatment process, Journal of Materials Processing Technology, Vol. 182, 2007, pp. 65-72.