Weldability and thickness study of electroless nickel coating on aluminium conductor for Li-ion battery pack

Main Article Content

Abstract

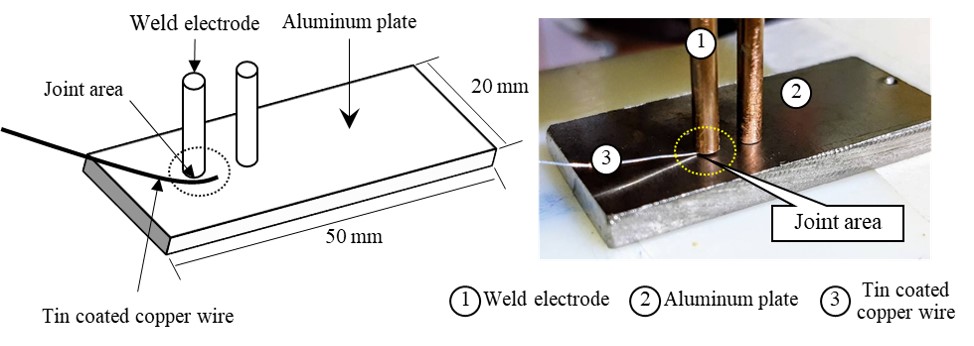

Aluminium (Al) is used as an electrical conductor for battery modules to reduce the cost of battery modules but still provides high performance. An electroless nickel (EN) coating is applied to the surface of the Al conductors to meet the mentioned requirements, as it is well known in the automotive industry for its hardness and wear resistance. This paper presents a novel study on the influences of EN thickness on the weldability between the EN coated Al conductors and the tin coated copper wires using resistance spot welding (RSW). The two main parameters of this study are nickel (Ni) thickness and Al thickness. A total of twelve thickness conditions of the material are used. It consists of three differences in the thickness of Al; 2, 3 and 4 mm, that their surfaces are coated by four different thicknesses of Ni; uncoated, 10 µm, 20 µm and 30 µm. The electrical conductivity, the pull force and the peel force are measured after the specimens are welded with the tin coated copper wires. Poor and good weldabilities are studied to discover the cause of the behaviours. This study assists the primary purpose of using Al as the electrical conductor for battery modules, reducing the cost of battery modules but still offering high performance.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

References

Bal Seal Engineering Inc. Electroless nickel plating: A general description of electroless nickel plating and its effect on Bal Seal spring-energized seal performance in reciprocating and rotary service, 2015, Bal Seal Engineering, USA.

Zwicker, M.F.R., Moghadam, M., Zhang, W., Nielsen, C.V. Automotive battery pack manufacturing – A review of battery to tab joining, Journal of Advanced Joining Processes, Vol. 1, 2020, pp. 100017.

Warner, J.T. The Handbook of Lithium-ion battery pack design: Chemistry, components, types and terminology, 2015, Elsevier, Miami.

Rothgang, S., Baumhöfer, T., van Hoek, H., Lange, T., De Doncker, R.W., Sauer, D.U. Modular battery design for reliable, flexible and multi-technology energy storage systems, Applied Energy, Vol. 137, 2015, pp. 931-937.

Lee, S.S., Kim, T.H., Hu, S.J., Arbor, A., Cai, W.W., Abell, J.A. Joining technologies for automotive Li-ion battery manufacturing – A review, paper presented in Proceedings of the ASME 2010 International Manufacturing Science and Engineering Conference, 2010, ASME, Pennsylvania.

Brand, M.J., Schmidt, P.A., Zaeh, M.F., Jossen, A. Welding techniques for battery cells and resulting electrical contact resistances, Journal of Energy Storage, Vol. 1, 2015, pp. 7-14.

Masomtob, M., Sukondhasingha, R., Becker, J., Sauer, D.U. Parametric study of spot welding between Li-ion battery cells and sheet metal connectors, Engineering Journal, Vol. 21, 2017, pp. 457-473.

Gaines, L. and Cuenca, R. Costs of Lithium-ion batteries for vehicles, Energy, Vol. 48, 2000, pp. 73.

Kirkpatrick, L. Aluminum electrical conductor handbook, 1982, Aluminum Association, Washington.

NDT Education Resource Center. Conductivity and Resistivity values for aluminum & alloys, 2002, NDT Education, USA.

NDT Education Resource Center. Conductivity and Resistivity values for copper & alloys, 2007, NDT Education, USA.

Lewchalermwong, N., Masomtob, M., Lailuck, V., Charoenphonphanich, C. Material selection and assembly method of battery pack for compact electric vehicle, IOP Conference Series: Materials Science and Engineering, Vol. 297, 2018, pp.1-11.

Parkinson, R. Properties and applications of electroless nickel, 1997, Nickel Development Institute, USA.

McKeown, M. Interconnecting Li-ion cells options: Wire bonding, ribbon bonding, smart welding, and thermosonic smart welding, 2020, CHARED EVs, USA.

Allmann, C., Schussler, M., Landgraf, J. Forschungsprojekt e performance, 2014, Cuvillier Verlag, Göttingen.

Tesla battery Module Controller, EVTV Monitor / Controller For Tesla Model S Battery Modules 3, 2017, Tesla, USA.

Ambasankaran, C. and Sarojini, K.A. Electroless Nickel plating and its applications, IETE Journal of Research, Vol. 9, 1963, pp. 309-315.

Manladan, S.M., Yusof, F., Ramesh, S., Fadzil, M., Luo, Z., Ao, S. A review on resistance spot welding of aluminum alloys, The International Journal of Advanced Manufacturing Technology, Vol. 90, 2017, pp. 605-634.

Zhou, Y., Gorman, P., Tan, W., Ely. K.J. Weldability of thin sheet metals during small-scale resistance spot welding using an alternating-current power supply, Journal of Electronic Materials, Vol. 29, 2000, pp. 1090-1099.

Atílio, I., Braga, V., de Siqueira, R.H.M,, de Carvalho, S.M. de Lima, M.S.F. Comparing the weldability of AA6013-T4 aluminium alloy on DP600 dual-phase steel with laser welding and resistance spot welding, Journal of the Brazilian Society of Mechanical Sciences and Engineering, Vol. 42, 2020, pp. 1-12.

Weman, E. Welding processes handbook: Woodhead publishing series in welding and other joining technologies, 2nd edition, 2012, Woodhead Publishing, UK.

Habashi, F. Nickel, physical and chemical properties BT - Encyclopedia of Metalloproteins, 2013, Springer, New York.

Hall, D. and Lutsey, N. Effects of battery manufacturing on electric vehicle life-cycle greenhouse gas emissions, ICCT Brief, Vol. 12, 2018, pp. 1-12.