Thermodynamic and economic analyses of power generation from gas turbine exhaust

Main Article Content

Abstract

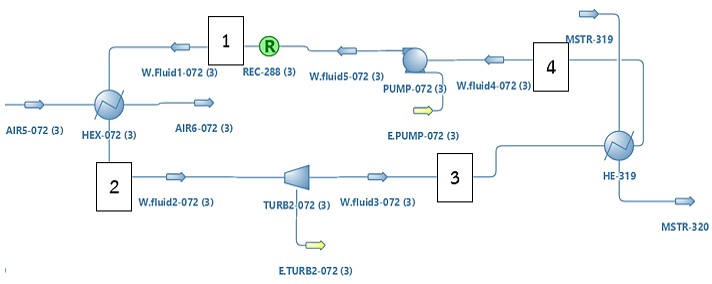

This paper presents the development of a thermodynamic model of natural gas production processes on the offshore platform by applying Organic Rankine Cycle (ORC) technology to the plant. This research considered the thermodynamic performance and economic feasibility of using ORC for electricity production from exhaust gas generated by gas turbine engines which were used as prime movers to drive natural gas compressors. According to the Process & Instrumentation Diagram (P&ID), the process of recovering waste heat from Booster Compression and Sales Gas Compression and Export modules from the entire gas production processes of the plant has been modeled in DWSIM program which is an open-source chemical process simulation. The simulation result showed that the exhaust gas had a temperature at 527 oC at Booster Compression and 504 oC at Sale Gas Compression and Export. The ORC was designed as a simple cycle with no degree of superheating and subcooling due to limited area of the offshore platforms. We have selected the most suitable working fluid for ORC in order to get the highest turbine power and efficiency. From the simulation, Toluene was identified as the most suitable working fluid which provided the highest turbine power and efficiency at 1.9 MW and 24.33%, respectively. So, the installation of 4 cycles of ORC for offshore platform will get total energy at 7.6 MW. To demonstrate the commercial feasibility of this project, a detailed economic analysis has been performed. The results showed that the ORC technology has the net present value (NPV) is 40.141 million Baht, the payback period (PB) is around 16.49 years, the internal rate of return (IRR) is 8.18% per year (from the minimum attractive rate of return or MARR at 8% per year) and the benefit cost ratio (B/C ratio) is 1.10. All indicators show economically favorable results, thus, indicating that this research is economically feasible and worth for the investment.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

References

Quoilin, S., Van Den Broek, M., Declaye, S., Dewallef, P., Lemort, V. Techno-economic survey of Organic Rankine Cycle (ORC) systems, Renewable and Sustainable Energy Reviews, Vol. 22, 2013, pp. 168-186.

Lapchit, P. and Kittijungjit, T. Thermodynamic and economic analyses of power generation from gas turbine exhaust (Bachelor's thesis), 2020, King Mongkut’s University of Technology Thonburi, Bangkok, Thailand.

Thurairaja, K., Wijewardane, A., Jayasekara, S., Ranasinghe, C. Working fluid selection and performance evaluation of ORC, paper presented in The 5th International Conference on Power and Energy Systems Engineering, 2018, Nagoya, Japan.

Nami, H., Ertesvåg, I.S., Agromayor, R., Riboldi, L., Nord, L.O. Gas turbine exhaust gas heat recovery by organic Rankine cycles (ORC) for offshore combined heat and power applications - energy and exergy analysis, Energy, Vol. 165, 2018, pp. 1060-1071.

Khosravi, H., Salehi, G.R., Azad, M.T. Design of structure and optimization of organic Rankine cycle for heat recovery from gas turbine: The use of 4E, advanced exergy and advanced exergoeconomic analysis, Applied Thermal Engineering, Vol. 147, 2017, pp. 272-290.

Mohammadkhani, F., Shokati, N., Mahmoudi, S., Yari, M., Rosen, M. Exergoeconomic assessment and parametric study of a Gas Turbine-Modular Helium Reactor combined with two Organic Rankine Cycles, Energy, Vol. 65, 2014, pp. 533-543.

Tartière, T. and Astolfi, M. A world overview of the organic Rankine cycle market, Energy Procedia, Vol. 129, 2017, pp. 2-9.

Medeiros, D. DWSIM - Chemical Process Simulator, URL: http://dwsim.inforside.com.br/wiki/index.php?title =DWSIM, accessed on 01/09/2020, 2020.

Tangsriwong, K., Lapchit, P., Kittijungjit, T., Klamrassamee, T., Sukjai, Y., Laoonual, Y. Modeling of chemical processes using commercial and open-source software: A comparison between Aspen Plus and DWSIM, IOP Conference Series: Earth and Environmental Science, Vol. 463, 2020, pp. 012057.

Jain, R., Moudgalya, K.M., Fritzson, P., Pop, A. Development of a Thermodynamic Engine in OpenModelica, paper presented in Proceedings of the 12th International Modelica, 2017, Prague, Czech Republic.

Çengel, Y.A. and Boles, M.A. Thermodynamics: An engineering approach, 2008, McGraw-Hill, Bangkok.

Piriyawat, S. Engineering Economics, URL: http://www.surames.com/images/column_1227454933/ chapter%206%20engineering%20economic.pdf, accessed on 08/10/2020, 2020.

Tchanche, B.F., Quoilin, S., Declaye, S., Papadakis, G., Lemort, V. Economic feasibility study of a small scale organic rankine cycle system in waste heat recovery application, paper presented in Engineering Systems Design and Analysis, 2010, Istanbul, Turkey.

Sinnott, R.K., Coulson, J.M., Richardson, J. F. Coulson & Richardson's chemical engineering: Vol. 6, 2005, Elsevier, Oxford.

Campbell, A., Hanania, J., Jenden, J., Stenhouse, K., Donev, J. Barrels of oil equivalent, Energy Education, URL: https://energyeducation.ca/encyclopedia/Barrels_of_oil_equivalent#:~:text=Since%20average%20dome stic%20crude%20oil,5.7%20MTUs%20or%201.7%20MWh, accessed on 15/02/2020, 2018.