Vision-based automatic leak detection for short pipes in waterworks industry

Main Article Content

Abstract

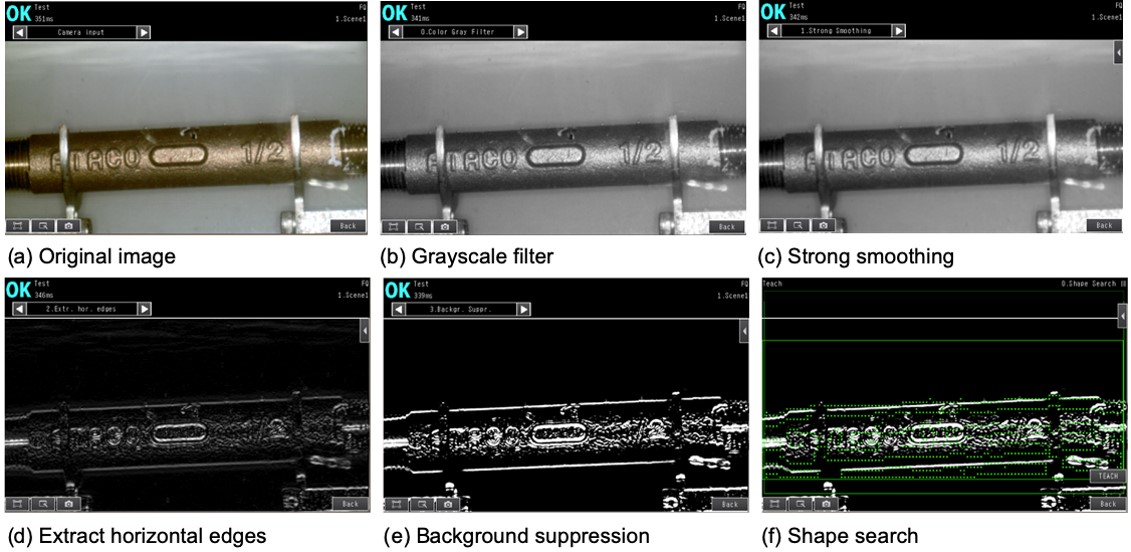

One of the most common and widely used products in waterworks solution are short pipes. A number of manufacturing processes are involved in the production phase of these workpieces. Defection can be found in various forms in regard to the manufacturing processes, from the material forming to machining process. One of the most common defection found is related to the material porosity which leads to the leak problem. In this research, automatic leak detection system is designed and developed in order to inspect short pipes. The workpieces are submerged under water and bubbles will be detected by the vision-based detection algorithm to justify the leak. From the experiments, the inspection process took 15 seconds. The detection exhibited 0% false positive and 10% false negative. In addition, the production line has been transformed to a continuous line so that the the number of operators is reduced from 3 to 1.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

References

SciLution Co., Ltd. Leak Tester Automatic Machine TL Series, URL: https://www.scilution.co.th/product/leak-tester-tl, accessed on 03/12/2020, 2020.

General Vacuum & Flow Co., Ltd. Helium Leak Detection, URL: https://www.vacuumthai.com/Helium_Leak_Detection, accessed on 03/12/2020, 2017.

Li, B., Hou, D., Wang, X., Ba, D. Study on the influence of the position of precise detection port on the performance of helium mass spectrometer leak detector, Chinese Journal of Scientific Instrument, Vol. (11), 2020, pp. 58-65.

Schnaidman, A. Leak detection using helium as a tracer gas and the primus line solution for pipe rehabilitation, paper presented in 37th International NO-DIG Conference and Exhibition, 2019, Florence, Italy.

Vinogradov, M.L., Kostrin, D.K., Karganov, M.V., Tiskovich, V.Y. How to choose a leak detection method, paper presented in 2016 IEEE NW Russia Young Researchers in Electrical and Electronic Engineering Conference (EIConRusNW), 2016, Petersburg, Russia.

Shin, Y.H., Hong, S.S., Lim, I.T., Chung, K.H. The effect of the operational conditions on the quantitative leak rate of leak detectors, Key Engineering Materials, Vol. 321-323, 2006, pp. 1560-1563.

Shu, X., Li, H., Qin, Z., Liu, L., Deng, M., Zhang, D. Leak detection by testing vapor in tank foundation, paper presented in 2014 IEEE Far East Forum on Nondestructive Evaluation/Testing, 2014, Chengdu, China.

Garcia, A., Ferrando, J.L., Arbelaiz, A., Oregui, X., Bilbao, A., Etxegoien, Z. Soft computing analysis of pressure decay leak test detection, paper presented in 15th International Conference on Soft Computing Models in Industrial and Environmental Applications (SOCO 2020), 2020, Burgos, Spain.

Gao, F., Lin, J., Ge, Y., Lu, S., Zhang, Y. A mechanism and method of leak detection for pressure vessel: whether, when, and how, IEEE Transactions on Instrumentation and Measurement, Vol. 69(9), 2020, pp. 6004-6015.

Wu, C.L., Pan, H.F., Xia, Y.M. Air-tightness detection system based on optical flow method, Journal of Electrical and Electronics Engineering, Vol. 30(8), 2013, pp. 947-951.

Gan, J.W., Qin, F.J., Cao, B. Design of FPGA image processing system for the bubble edge detection, Chinese Journal of Mechanical Engineering, Vol. 36(2), 2015, pp. 293-296.

Gualtiero, F., Santochi, M., Dini, G., Tracht, K., Scholz-Reiter, B., Fleischer, J., et al. Grasping devices and methods in automated production processes, CIRP Annals, Vol. 63(2), 2014, pp. 679-701.

OMRON Electronics Co., Ltd. Smart Camera FQ2-S/CH Series, URL: https://assets.omron.eu/downloads/manual/en/v4/z337_fq2-s_ch_smart_camera_users_manual_en.pdf, accessed on 03/12/2020, 2017.

Vongbunyong, S., Archeewawanich, P., Akaratham, P., Martchan, C., Thamrongaphichartkul, K. Automatic handling for valves trimming system, IOP Conference Series: Materials Science and Engineering, Vol. 501, 2019, pp. 1-7.