Fluid selection and optimal operating conditions of an ORC, and trilateral Rankine cycle power plant for a heat source temperature of 210°C - 250°C

Main Article Content

Abstract

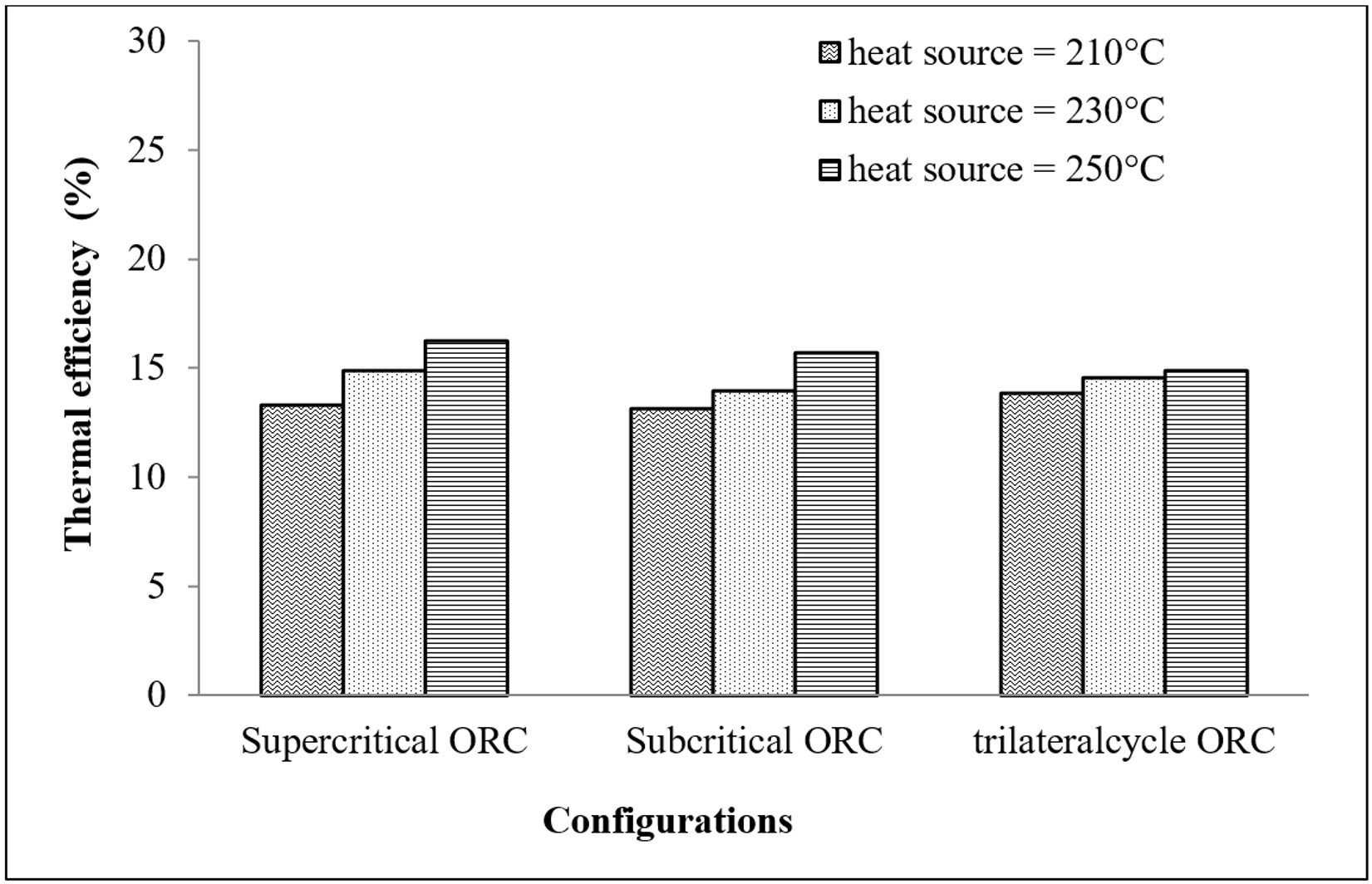

A selection of an appropriate working fluid for electricity production using a heat source of 210°C - 250°C was conducted. Three types of power plants were examined. They are a subcritical ORC (organic Rankine cycle), supercritical ORC, and trilateral Rankine cycle (TLC) power plants. An optimal operating condition for each working fluid and each power plant type was searched by using the golden section search method. A MATLAB code was developed and used in this simulation. The thermodynamic properties of the working fluids were calculated by using NIST REFPROP program. The justification of the code was validated with a result taken from the literature. The maximum net output was obtained when using the supercritical ORC plant with R141b as its working fluid and the heat source temperature is at 250°C. That plant produces a power of 141.72 kW and the cycle efficiency is 16.25%. The maximum net power output of 133.40 kW and cycle efficiency of 15.70% are obtained from the subcritical plant with pentane as its working fluid and is used as the working fluid and the heat source temperature is also at 250°C. Moreover, the net power outputs of 133.82 kW and cycle efficiency of 14.90% are obtained when using R141b as the working fluid in the TLC power plant. According to the off-design simulations, an appropriate adjustment of the working fluid flow rate can regulate the net power output.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

References

Neshumayev, D., Rummel, L., Konist, A., Ots, A. and Parve, T. Power plant fuel consumption rate during load cycling, Applied Energy, Vol. 224, 2018, pp. 124-135.

Rewlay-Ngoen, C., Papong, S. and Sampattagul, S. The NPP and social asset impacts of acidification from coal-fired power plant in Thailand, Energy Procedia, Vol. 52, 2014, pp. 234-241.

Sinha, S. and Nag, P. Air pollution from solid fuels, Encyclopedia of Environmental Health, Vol. 118, 2011, pp. 46-52.

Palagi, L., Pesyridis, A., Sciubba, E. and Tocci, L. Machine learning for the prediction of the dynamic behavior of a small scale ORC system, Energy, Vol. 166, 2019, pp. 72-82.

Hoang, A.T. Waste heat recovery from dieselengines based on Organic Rankine Cycle, Applied Energy, Vol. 234, 2018, pp. 138-166.

Department of Alternative Energy Development and Energy Conservation, Ministry of Energy, Thailand. Renewable Energy Report, URL: http://www.dede.go.th, accessed on 27/03/2019.

Firth, A., Zhang, B. and Yang, A. Quantification of global waste heat and its environmental effects, Applied Energy, Vol. 235, 2019, pp.1314-1334.

Yalı, H., Koç, Y., Koç, A., Görgülü, A. and Tandirolu, A. Parametric optimization and exergetic analysis comparison of subcritical and supercritical organic rankine cycle (ORC) for biogas fuelled combined heat and power (CHP) engine exhaust gas waste heat, Energy, Vol. 111, 2016, pp.923-932.

Xu, G., Song, G., Zhu, X., Gao, W., Li, H. and Quan, Y. Performance evaluation of a direct vapor generation supercritical ORC system driven by linear Fresnel reflector solar concentrator, Applied Thermal Engineering, Vol. 80, 2015, pp. 196-204.

Li, J., Liu, Q., Ge, Z., Duan, Y. and Yang, Z. Thermodynamic performance analyses and optimization of subcritical and transcritical organic rankine cycles using R1234ze(E) for 100–200 °C heat sources, Energy Conversion and Management, Vol. 149, 2017, pp. 140-154.

Pantaleo, A., Fordham, J., Oyewunmi, O. and Markides, C. Intermittent waste heat recovery via ORC in coffee torrefaction, Energy Procedia, Vol. 142, 2017, pp. 1714-1720.

Cipollone, R., Battista, D.D. and Bettoja, F. Performances of an ORC power unit for waste heat recovery on heavy duty engine, Energy Procedia, Vol. 129, 2017, pp. 770-777.

Yari, M., Mehr, A., Zare, V., Mahmoudi, S. and Rosen, M. Exergoeconomic comparison of TLC (trilateral Rankine cycle), ORC (organic Rankine cycle) and Kalina cycle using a low grade heat source, Energy, Vol. 83, 2015, pp. 712-722.

Benato, A., Stoppato, A., Mirandola, A. and Medico, M.D. Design and off-design analysis of an ORC coupled with a micro-gas turbine, Energy Procedia, Vol. 129, 2017, pp. 551-558.

Cao, Y. and Dai, Y. Comparative analysis on off-design performance of a gas turbine and ORC combined cycle under different operation approaches, Energy Conversion and Management, Vol. 135, 2017, pp. 84-100.

Hærvig, J., Sørensen, K. and Condra, T. Guidelines for optimal selection of working fluid for an organic Rankine cycle in relation to wastes heat recovery, Energy, Vol. 96, 2016, pp. 592-602.

He, C., Liu, C., Gao, H., Xie, H., Li, Y., Wu, S., et al. The optimal evaporation temperature and working fluids for subcritical organic rankine cycle, Energy, Vol. 38, 2012, pp. 136-143.

Radulovic, J. and Castaneda, N. I. On the potential of zeotropic mixtures in supercritical ORC powered by geothermal energy source, Energy Conversion and Management, Vol. 88, 2014, pp. 365-371.

Fischer, J. Comparison of trilateral cycles and organic rankine cycles, Energy, Vol. 36, 2011, pp. 6208-6219.