Waste heat recovery power plant for a heat source temperature of 130 - 150°C

Main Article Content

Abstract

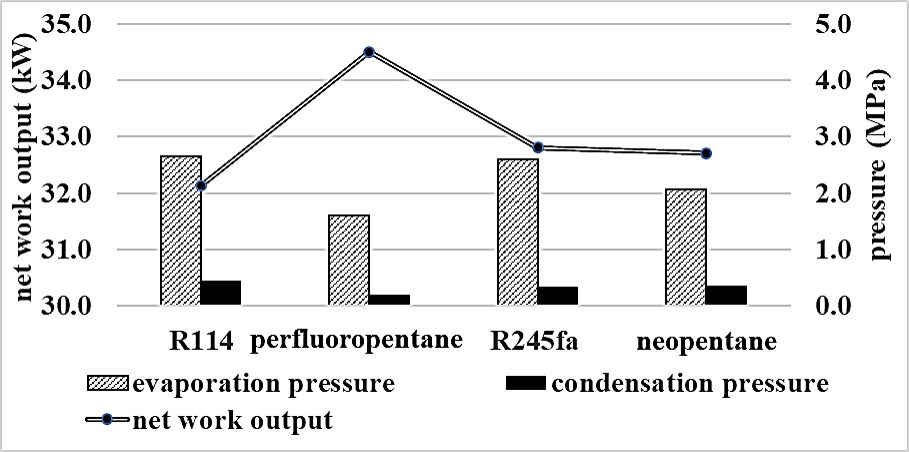

Organic Rankine cycle (ORC) is a promising technology for power generation that uses low-temperature heat from various sources including renewable energy and waste heat. The objective of this study is to design thermodynamically a subcritical ORC, supercritical ORC, and trilateral Rankine cycle (TLC) power plants that can provide the highest net power output when the heat source temperature is 130 - 150°C. A numerical model was developed using MATLAB. The thermophysical properties of the working fluids studied are calculated by NIST REFPROP program. The simulations show that the subcritical plant with RC318 as its working fluid provides the highest net power when the heat source temperatures are at 130°C and 140°C. The corresponding net powers are 15.6 kW and 23.08 kW, respectively. While one with perfluoropentane as it working fluid provides the highest net power when the heat source temperatures is at 150°C and the net power is 26.3 kW. The supercritical plant with R1216 as its working fluid provides the highest net power of 17.1 kW when the heat source temperatures is at 130°C. Meanwhile the plant with RC318 as its working fluid provides the highest net power of 24.2 and 31.5 kW when the heat source temperatures are at 140°C and 150°C, respectively. On the other hand, the TLC power plant with perfluoropentane as its working fluid provides the highest power output over the whole range of the heat source temperature studied. Its corresponding power output are 21 kW, 27.2 kW, and 34.5 kW, respectively. Additionally, the off-design simulations when the heat source temperatures were varied in the range of 125 - 155°C were conducted and it was found that a proper adaptation of the operating conditions (evaporation and condensation pressures, working fluid flow rate) can maintain a constant power output.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

References

Department of Alternative Energy Development and Efficiency. Thailand alternative energy situation, URL: https://www.dede.go.th, accessed on 2019 27/03/2019, 2017.

Kajurek, J. Influence of working fluid properties on the performance of organic rankine cycle, 2016, Instytut Techniki Cieplnej, Poland.

Kajurek, J., Rusowicz, A. and Grzebielec, A. The influence of stack position and acoustic frequency on the performance of thermoacoustic refrigerator with the standing wave, Archives of Thermodynamics, Vol. 38(4), 2017, pp. 89-107.

Yu, C., Xu, J. and Sun, Y. Transcritical pressure Organic Rankine Cycle (ORC) analysis based on the integrated-average temperature difference in evaporators, Applied Thermal Engineering, Vol. 88, 2015, pp. 2-13.

Chen, Q., Xu, J. and Chen, H. A new design method for Organic Rankine Cycles with constraint of inlet and outlet heat carrier fluid temperatures coupling with the heat source, Applied Energy, Vol. 98, 2012, pp. 562-573.

Li, Z., Lu, Y., Huang, Y., Qian, G., Chen, F., Yu, X., et al. Comparison study of trilateral rankine cycle, organic flash cycle and basic organic rankine cycle for low grade heat recovery, Energy Procedia, Vol. 142, 2017, pp. 1441-1447.

Roy, J.P., Mishra, M.K. and Misra, A. Parametric optimization and performance analysis of a waste heat recovery system using Organic Rankine Cycle, Energy, Vol. 35(12), 2010, pp. 5049-5062.

Hettiarachchi, H.M., Golubovic, M., Worek, W.M. and Ikegami, Y. Optimum design criteria for an organic Rankine cycle using low-temperature geothermal heat sources, Energy, Vol. 32(9), 2007, pp. 1698-1706.

Li, M., Wang, J., He, W., Gao, L., Wang, B., Ma, S., et al. Construction and preliminary test of a low-temperature regenerative Organic Rankine Cycle (ORC) using R123, Renewable energy, Vol. 57, 2013,

pp. 216-222.

Dai, X., Shi, L., An, Q. and Qian, W. Thermal stability of some hydrofluorocarbons as supercritical ORCs working fluids, Applied Thermal Engineering, Vol. 128, 2018, pp. 1095-1101.

Yari, M., Mehr, A.S., Zare, V., Mahmoudi, S.M.S. and Rosen, M.A. Exergoeconomic comparison of TLC (trilateral Rankine cycle), ORC (organic Rankine cycle) and Kalina cycle using a low grade heat source, Energy, Vol. 83, 2015, pp. 712-722.

Fischer, J. Comparison of trilateral cycles and organic Rankine cycles, Energy, Vol. 36(10), 2011, pp. 6208-6219.

Lemmon, E.W., Huber, M.L. and McLinden, M.O. NIST Standard Reference Database 23: Reference Fluid Thermodynamic and Transport Properties-REFPROP, Version 9.1, National Institute of Standards and Technology, 2013.

Hærvig, J., Sørensen, K. and Condra, T.J. Guidelines for optimal selection of working fluid for an organic Rankine cycle in relation to waste heat recovery, Energy, Vol. 96, 2016, pp. 592-602.