Improvement of a micromanipulation system by using a functional surface with a groove structure

Main Article Content

Abstract

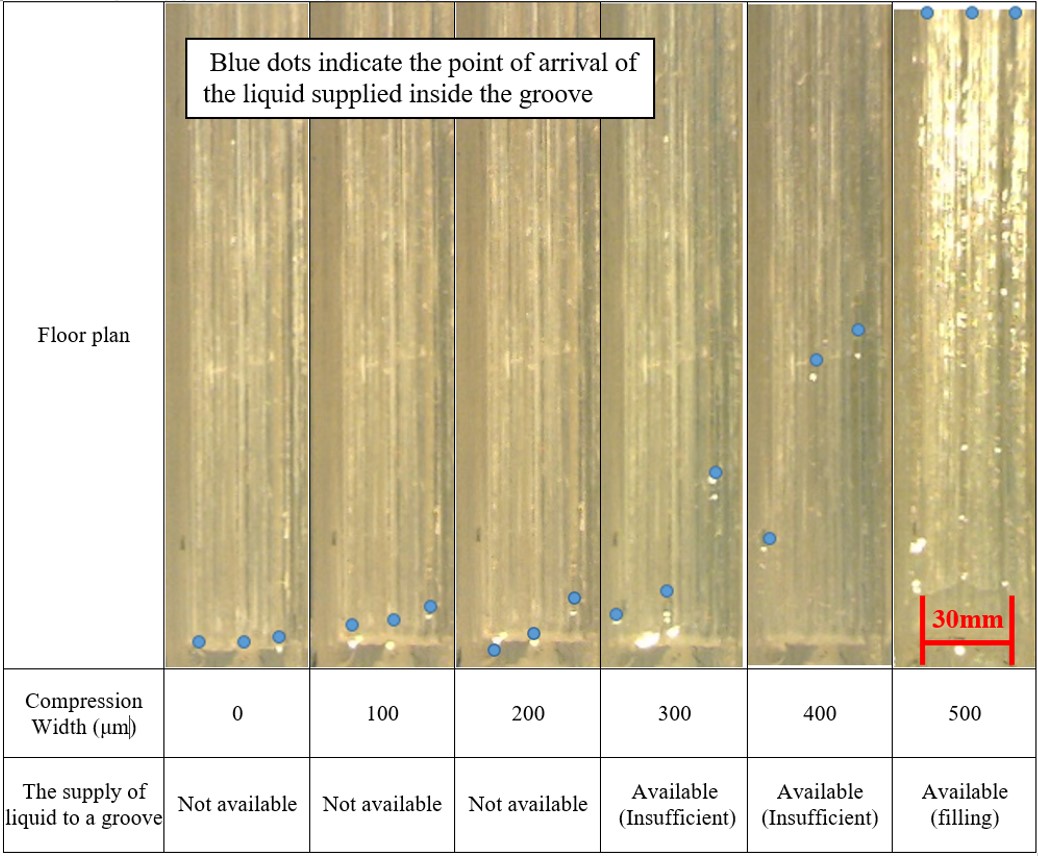

The demand for micro parts like a micro electron mechanical system has increased in recent times. With that, the improvement in the functions of micromanipulation equipment operating the minute object is required. Physical phenomena at the microscale differ from those of the normal scale due to the “scale effect”. In micromanipulation task, when the grasped object is placed at an arbitrary position, the natural fall of the object by gravity cannot be expected. This is because it is difficult to arrange an object at an arbitrary position. In this study, a method to place an object at an arbitrary position by generating a force between the floor and the object is proposed. The floor of functional surface has a fine groove into which enough liquid is injected to generate a liquid bridging force between the floor surface and a small object. The width of the groove can is reduced by applying an area load to the floor which generates a liquid cross-linking force corresponding to the size of the object. As the grooves become finer, the capillary phenomenon occurs. Therefore, the liquid can be supplied to the groove regardless of the attitude of the floor surface. By using the proposed floor surface, the speed and stability of the work in which the object in the micro manipulation work is placed on the floor surface is improved, and contributes to the development of the micro manipulation function.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

References

Sonia, L. and Aurelio, S. Design of an electro-thermally actuated cell microgripper, Microsystem Technologies, Vol. 20, 2014, pp. 869-877.

Shigeki, S., Hideo, H. and Kunio, T. Electrostatic detachment of an adhering particle from a micromanipulated probe, Journal of Applied Physics, Vol. 93, 2003, pp. 2219-2224.

Shoiti, N., Hemthavy, Pa., Kunio, T. and Shigeki, S. Micromanipulation of liquid bridging force under scanning electron microscopy, The Japan Society for Precision Engineering, 2015, pp. 803-804.

Kishan, D., Peter, R. and Min, G. Optical micromanipulation, The Royal Society of Chemistry, Vol. 37, 2008, pp. 42-55.

Chen, T., Wang, Y., Yang, Z., Liu, H., Liu, J. and Sun, L. A PZT actuated triple-finger gripper for multi-target micromanipulation, Micromachines, Vol. 8, 2017, pp. 33.

Daigo, M., Ryuhei, K., Satoshi, N. and Shigeomi, K. Use of AR/VR in micro manipulation support system for recognition of monocular microscopic images, International Journal of Automation Technology, Vol. 5, 2011, pp. 886-874.

Daigo, M., Syuhei, Y. and Kyuhei T. Fabricating the active functional surface for micromanipulation, paper presented in the Proceeding of the 8th International Conference on Positioning Technology, 2018, Kaohsiung, Taiwan.

Kaiji, S., Kentaro, I., Seiichi, H. and Akira, S. Self-alignment of microparts using liquid surface tension-behavior of micropart and alignment characteristics, Precision Engineering, Vol. 27, 2003, pp. 42-50.

Katsuo, M., Shungo, A. Naoki, T., Tomoya, I. and Tohru, N. Electrowetting on dielectric (EWOD) device with dimple structures for highly accurate droplet manipulation, Applied Science, Vol. 9, 2019, pp. 1-9.

Nobuyuki, M. Surface function based on microstructure, 2011, Morikita Publishing, Japan.

Shu, O. Surface tension, 1980, Iitate Publishing, Japan.

Yoshiyuki, E., Yasuo, K. and Yasunobu, N. Analysis of liquid bridging adhesion between two particles, The Society of Chemical Engineers, Japan, Vol. 19, 1993, pp. 55-61.