Semi-Automatic system for setup process of forging machine

Main Article Content

Abstract

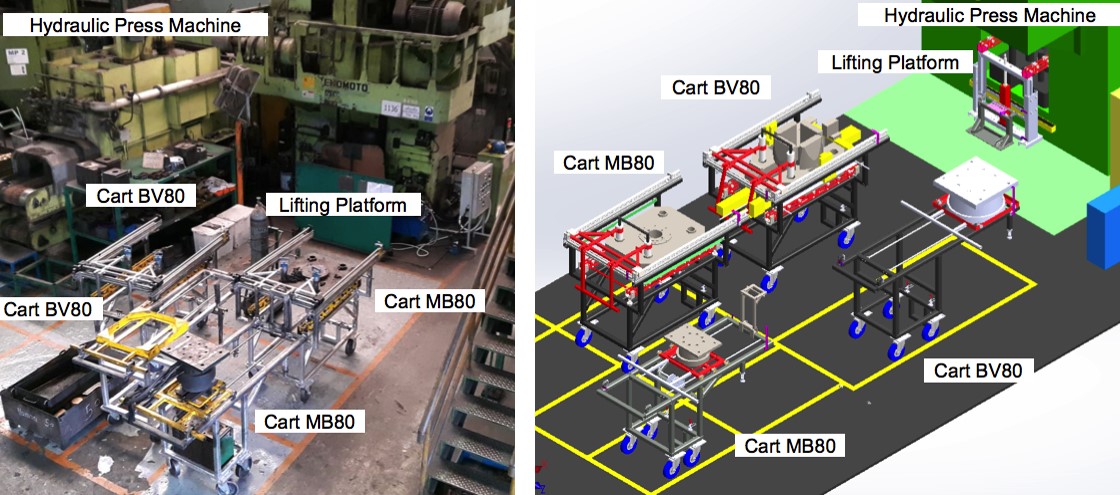

Forging is one of the important techniques for bulk metal deformation processes for producing high-strength parts. Metal workpieces are inserted into the cavity between die pieces to form particular shape. The workpiece can be produced with a short cycle time with a hydraulic press. However, the setup process for forging machines takes time due to numerous complicated steps. In this research, a semi-automatic system is developed to improve the machine setup process in regard to positioning of large dies and components. Toyota Production System (TPS) is used to improve the process. The system consists of movable carts integrated with sensors and actuators in order to facilitate the operation. In this case, the prototype system can reduce the setup time by 65% and the operators can work more safely and effectively.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

References

Groover, M.P. Bulk deformation processes in metal working, in Fundamentals of Modern Manufacturing: Materials, Processes, and Systems, 2010, John Wiley & Sons, USA, p. 405-420.

Vongbunyong, S., Archeewawanich, P., Akaratham, P., Martchan, C. and Thamrongaphichartkul, K. Automatic handling for valves trimming system. IOP Conference Series: Materials Science and Engineering, Vol. 501, 2019, pp. 1-7.

Andrade, F.d. Machine Set Up Definition. URL: https://www.academia.edu/10073499/Machine_Set_Up_

Definition, accessed on 2019.

Shingo, S. A revolution in manufacturing: The SMED system, 1985, Productivity Press, New York .

Kušar, J., Berlec, T., Žefran, F. and Starbek M. Reduction of machine setup time. Strojniski Vestnik/Journal of Mechanical Engineering, Vol. 56(12), 2010, pp. 833-845.

Kosmek. Quick die change systems for press machines, 2017, Japan, URL: http://www.kosmek.co.jp/english/products/qdcs/, accessed on 2019.

Akshay Bule, A., Kalpande, S.D., Deore, A., Joshi, P. and Gosavi, S. Implementation of hydraulic quick die clamping system, International Journal of Advance Research Ideas and Innovations in Technology, Vol. 3(2), 2017, pp. 723-726.

Dimeco. Tool Changeover System for Lean Manufacturing, 2018, Oiartzun, Spain, URL: http://www.dimeco.com/dimeco-solutions/quick-die-change-rotobloc/, accessed on 2019.

Dimeco. Quick Die Change - Die/tool loading/handling equipment - Rotobloc-PSP Dimeco, 2011, URL: https://www.youtube.com/watch?v=iDoHxzCiX3I, accessed on 2019.

Art of Lean. Toyota production system basic handbook, 2019, Art of Lean, California.