An Application of Six Sigma to Reduce Defects from the Precast Concreate Processing: a Case Study of Company A

Main Article Content

Abstract

Precast concretes are widely used in construction because it can reduce production costs and construction time. However, factories have encountered with the defects resulting from the production of precast concrete process. This research aims to reduce the defects resulting from the precast concrete processing through action research methodology. It includes four phases

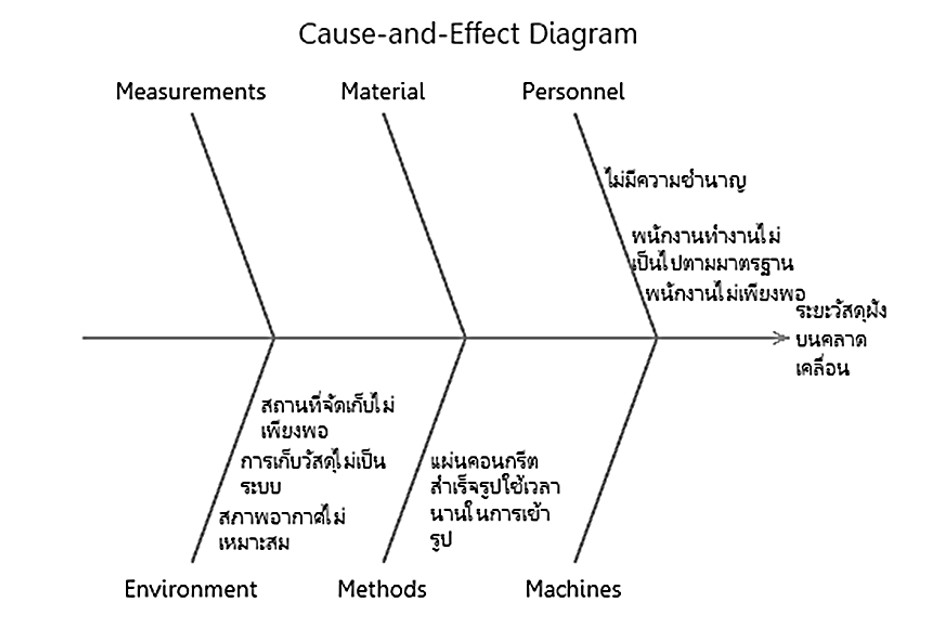

1) problem identification 2) action planning 3) tacking action and 4) evaluation. In taking action phase, six sigma methodology was implemented through the collocation between researcher and participants. Six sigma methodology consists of five steps: define, measure, analyze, improve and control (DMAIC). The results showed that before the improvements the sigma level of precast concrete processing was 3.3, after the improvements by developing work standard procedures for precast concrete production and training of staff about purchasing of materials. The number of defects were reduced from 9 to 7 from per 36 pieces of production which accounted for 22.22 percent and the sigma level after the improvements was 3.5. The results of the research shown that the application of Six Sigma as a quality management tool can reduce defects from the precast production process. This research will be useful to plant managers or head of production who want to reduce defects in the production process and reduce production costs.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Articles published in Journal of Industrial Technology Ubon Ratchathani Rajabhat University both hard copy and electronically are belonged to the Journal.

References

T. Mahattanalai, “Industry Outlook 2021-2023: Construction Contractor.” Krungsri Research. Accessed: Aug. 21, 2022. [Online]. Available: https://www.krungsri.com/th/research/industry/industry-outlook/Construction-Construction-Materials/Construction-Contractors/IO/io-Construction-Contractors-21 (in Thai)

J. Antony. “Six Sigma vs Lean: Some perspectives from leading academics and practitioners,” Internatinal Jornal of Productivity and Performance Management, vol. 60, no.2, pp. 185–190, Jan. 2011.

P. Tanasanskulwong and U. Purintrapiban, “Application of Lean Six Sigma in wine glass manufacturing industry,” TNI Journal of Engineering and Technology, vol. 7, no. 1, pp. 22-31, Jun. 2019. (in Thai)

F. Ullah, M. J. Thaheem, S. Q. Siddiqui and M. B. Khurshid, “Influence of Six Sigma on project success in construction industry of Pakistan,” The TQM Journal, vol. 29, no. 2, pp. 276-309, Mar. 2017.

H. U. Rehman, M. Asif, M. A. Saeed, M. A. Akbar and M. U. Awan, “Application of Six Sigma at cell site construction: a case study,” Asian Journal on Quality, vol. 13, no. 3, pp. 212–233, Nov. 2012.

K. Urwongse, “Focus group discussion: effective qualitative data collection technique,” STOU Education Journal, vol. 12, no. 1, pp. 17-30. Jul. 2019. (in Thai)

J. Collis and R. Hussey, Business Research : a Practical Guide for Undergraduate & Postgraduate Students, 4th ed. Basingstoke, United Kingdom: Palgrave Macmillan, 2014.

L. Marakanon, J. Pilaket, N. Sakkongka and A. Ratana, “Waste reduction for precast concrete manufacturing process by using DMAIC technique,” Journal of Industrial Technology. vol. 14, no. 1, pp. 53-59. Jun. 2019. (in Thai)

W. Innupat, “Improvement of flocking process for automotive window frame rubber manufacturers based on Six Sigma principle,” M.S. independent study, Department of Business Engineering Management, Rajamangala University of Technology Thanyaburi, Pathum Thani, Thailand, 2017. (in Thai)