Design of Rice Post-Harvest Moisture Reduction Machine: A Case Study of Ban Ek Community, Yaa Plao Subdistrict, Mueang District, Sisaket Province

Main Article Content

Abstract

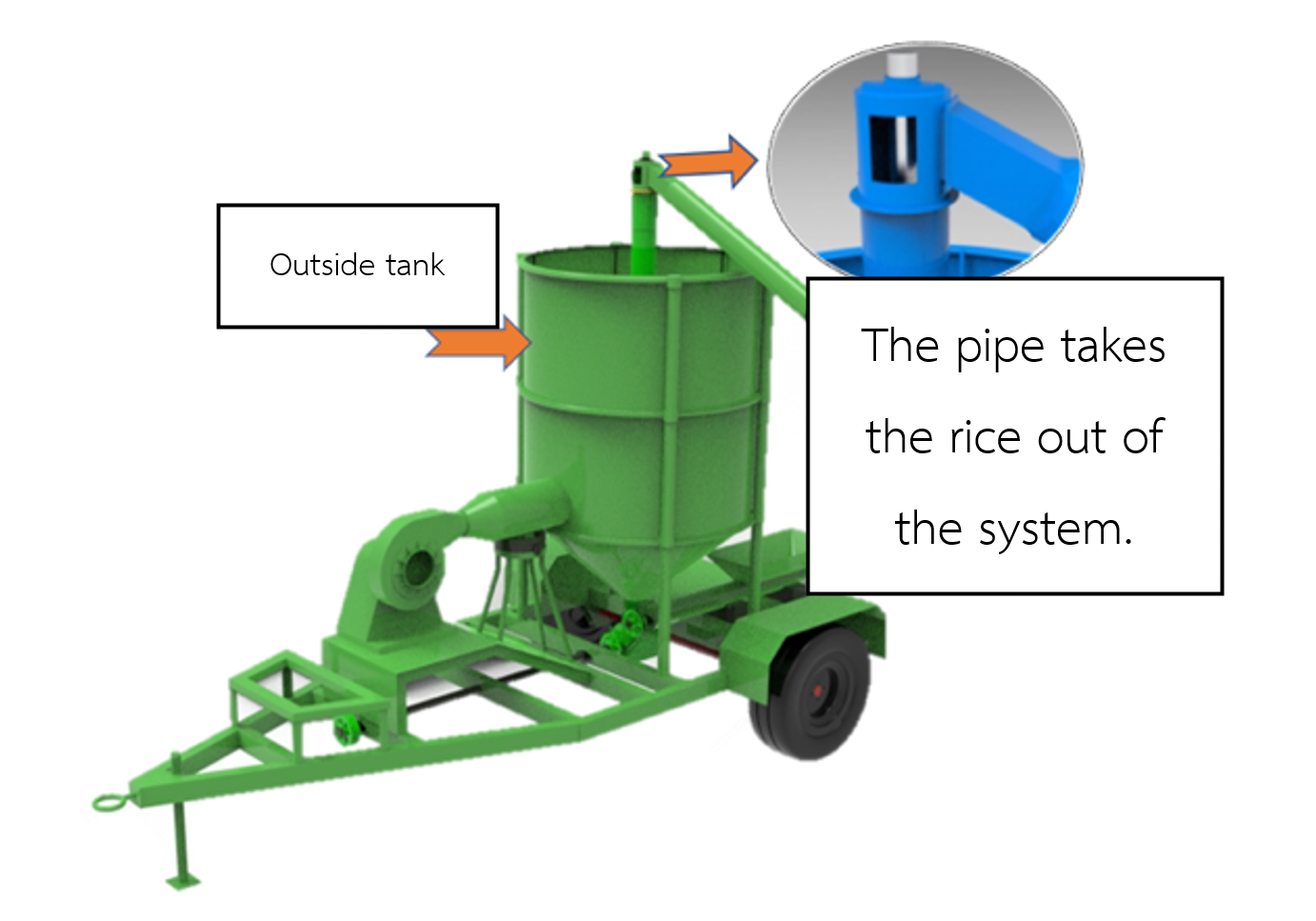

This research aims to 1) design and construct a paddy dryer to reduce the moisture content to 14 percent after harvesting and 2) to evaluate the efficiency of the paddy dryer after harvesting. The research procedure is divided into two steps: 1) study and develop a paddy dryer, design and construct an innovation for reducing the moisture content of paddy after harvesting. Use a 11.5 horsepower walk-behind tractor engine as the power source. The main components are a conical cylindrical temperature control tank, a set of paddy conveying screws, a set of hot air supply, a set of paddy outlet direction control, the amount of paddy for testing is 200 kilograms, and evaluate the efficiency. 2) Disseminate the innovation by transferring knowledge to farmers. The research results showed that it was possible to reduce the moisture content of paddy after harvesting to an average moisture content of 14 percent within an average time of 210 minutes. The average gas consumption was 900 grams per hour. The average oil consumption was 1.2 liters per hour. The total energy cost was 65 baht per hour. The energy cost per production cycle was 227.5 baht. When compared to the traditional method, it was found that the efficiency of moisture reduction using the moisture reduction innovation could reduce the moisture reduction time better than the traditional method. The target group's evaluation results in terms of design, satisfaction score 4.55, standard deviation 0.46, usability, satisfaction score 4.19, standard deviation 0.39, structure, satisfaction score 4.55, standard deviation 0.37, and overall evaluation results in all aspects, satisfaction score 4.43, standard deviation 0.41. The satisfaction level is statistically significant.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Articles published in Journal of Industrial Technology Ubon Ratchathani Rajabhat University both hard copy and electronically are belonged to the Journal.

References

National Agricultural Products Standards Office, "THAI AGRICULTURAL STANDARD," in "Good Agricultural Practices (GAP) for Rice Seeds," Bangkok: Ministry of Agriculture and Cooperatives, 2017, pp. 13-14.

Ya Plong Subdistrict Administrative Organization, Local Development Plan (2023 - 2027), Sisaket: Sisaket Province, 2022.

J. Wanichchang, P. Wanichchang, and A. K. Kittaporn, "Development of Continuous Flow Paddy Drying Machine," Journal of Agricultural Science, vol. 34, no. 4-6, pp. 130-133, 2003.

C. Nimble, "Development and Study of Paddy Dehumidification Process Using a Crossflow Dryer with Hot Air Recirculation System," King Mongkut's University of Technology North Bangkok, Bangkok, 2014.

K. Trongchitt, W. Chudachan, and L. Leoraj, "Easy-to-assemble solar paddy dryer," Elephant Science Journal, vol. 40, no. 2, pp. 76-90, 2018.

S. Ajbumrung, "High-Efficiency Solar Drying Cabinet," Department of Industrial Production Technology, Faculty of Engineering, Mahasarakham Rajabhat University, Mahasarakham Province, 2019.

N. Klaengkaew, "Study on the cost and return from rice cultivation of Tabon Non Thai farmers Nothai District Nakhon Ratchasima," Journal of Pathum Thani University, vol. 13, no. 01, pp. 188-192, 2021.

P. Chatwachirawong, "Cost and Break-Even Analysis from Sugarcane Production," in Feasibility Study Report on Using Technology to Increase Sugarcane Yield, Bangkok, pp. 64-73.

N. Klanwan, "The Development of a Mobile Rice Dryer for Farmers," Master's Thesis, Pibulsongkram Rajabhat University, Phitsanulok Province, 2017.

C. Maneerat, K. Chomchuen, W. Bucha, and S. Wisitsirikul, "Study on moisture content in paddy suitable for processing into milled rice," in The 2nd National Conference, Research and Development Institute Kamphaeng Phet Rajabhat University, Kamphaeng Phet, Thailand,

Dec. 2, 2015, pp. 213 - 219.