Improvement of Process Manufacturing Using Lean Six Sigma Production Techniques: A Case Study in the Food Industry

Main Article Content

Abstract

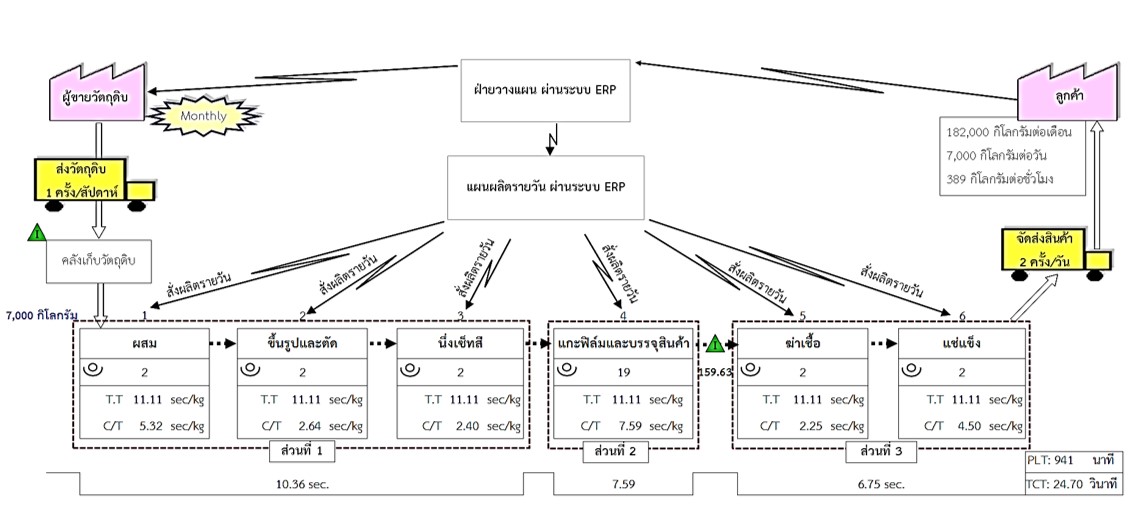

This research aimed to improve the seafood processing process using value stream mapping as a tool for data gathering and data analysis using DMAIC and implementing lean production techniques to increase productivity. A case study of the company can be summarized as follows. (define) productivity is lower than the set target of 4.26 kg/person*hour. (measure) the production line has an average productivity of 85.20%. Bottlenecks film peeling and packing process and inventory of work in process to 2,049 kg. (analyze) There are four root causes of the problem as follows: 1) Skills, 2) Machines, 3) Line balancing, and 4) Working standards (improve) ranking each root cause of the problem to impact more to less the order of importance before improvement as follows: 1) Line balancing: film unpacking and product packaging productivity average to 40.49%. 2) Machines: switch the cut position of a product productivity average to 83.79%. 3) Skills: rotate the packing position productivity average to 40.17 kg/hour. 4) Working standards define the new operating procedure productivity average to 37.68%. These research results are summarized: productivity increased on average to 14.40%. The bottleneck decreased by 70.35%. Productivity per hour increased to 18.14%. Production per person per hour increased to 53.80%. Direct labor costs decreased by 9.50%. Direct labor cost saved 33,410 baht per month.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Articles published in Journal of Industrial Technology Ubon Ratchathani Rajabhat University both hard copy and electronically are belonged to the Journal.

References

M. Prasanna and S. Vinodh, “Lean Six Sigma in SMEs: an exploration through Literature review,” Journal of Engineering, Design and Technology, vol. 11, no. 3, pp. 224-250, Oct. 2013.

J. Lapierre, “Customer-perceived value in industrial contexts,” Journal of Business & Industrial Marketing, vol. 15, no. 2/3, pp. 122-145, Apr. 2000.

M. Assarlind, I. Gremyr and K. Bäckman, “Multi-faceted views on a Lean Six Sigma application,” International Journal of Quality & Reliability Management, vol. 30, no. 4, pp. 387-402, Apr. 2013.

J. Dinis-Carvalho, F. Moreira, S. Bragança, E. Costa, A. Alves and R. J. Sousa, “Waste identification diagrams,” Production Planning & Control, vol. 26, no. 3, pp. 235-247, Jun. 2014.

J. D. Mast and J. Lokkerbol, “An Analysis of the Six Sigma DMAIC Method from the Perspective of Problem Solving,” International Journal of Production Economics, vol. 139, no. 2, pp. 604–614, Oct. 2012

E. V. Gijo, J. Antony, M. Kumar, R. McAdam and J. Hernandez, “An application of Six Sigma methodology for improving the first pass yield of a grinding process,” Journal of Manufacturing Technology Management, vol. 25, no. 1, pp. 125–135, Jan. 2014.

S. Kumar and M. Sosnoski, “Using DMAIC Six Sigma to systematically improve shopfloor production quality and costs,” International Journal of Productivity and Performance Management, vol. 58, no. 3, pp. 254-273, Mar. 2009.

M. Rother and J. Shook, Learning to see: value-stream mapping to create value and eliminate muda, Cambridge, MA, USA: The Lean Enterprise Institute, 2003.

S. S. Kumar and M. P. Kumar, “Cycle time reduction of a truck body assembly in an automobile industry by Lean principles,” Procedia Materials Science, vol. 5, pp. 1853-1862, Jan. 2014.

I. W. Taifa and D. A. Desai, “Quality function deployment integration with Kano model for ergonomic product improvement (Classroom furniture) - a review,” Journal of Multidisciplinary Engineering Science and Technology. vol. 2, no. 9, pp. 2484-91, Sep. 2015.

S. M. Motavallian and H. Settyvari, “Application of value stream mapping in product development,” M.S. thesis, Department of Technology Management & Economics, Chalmers University of Technology, Göteborg, Sweden, 2013.

D. Powell, S. Lundeby, L. Chabada and H. Dreyer, “Lean Six Sigma and environmental sustainability: the case of a Norwegian dairy producer,” International Journal of Lean Six Sigma, vol. 8, no. 1, pp. 53-64, Mar. 2017.

H. C. Hung and M. H. Sung, “Applying six sigma to manufacturing processes in the food industry to reduce quality cost,” Scientific Research and Essays, vol. 6, no. 3, pp. 580-591, Feb. 2011.