การเชื่อมโดยการแพร่ของทองเหลือง เกรด C3064 กับอะลูมิเนียมหล่อกึ่งของแข็ง เกรด 356 ที่ส่งผลต่อสมบัติทางกลและโครงสร้างทางโลหะวิทยา

Main Article Content

บทคัดย่อ

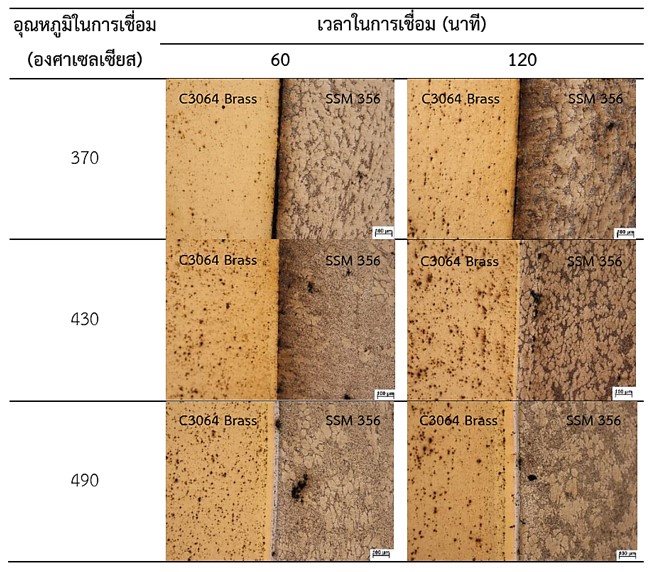

งานวิจัยนี้มีวัตถุประสงค์เพื่อศึกษาลักษณะของโครงสร้างทางโลหะวิทยาและสมบัติทางกลบริเวณรอยต่อของชิ้นงานจากกรรมวิธีการเชื่อมโดยการแพร่ต่างวัสดุระหว่างทองเหลือง เกรด C3064 กับอะลูมิเนียมหล่อกึ่งแข็ง เกรด 356 ชิ้นงานทดลองเชื่อม ขนาด 10×15×3 มิลลิเมตร กำหนดปัจจัยในกระบวนการเชื่อมโดยการแพร่ คือ เวลากดแช่ 60 นาที และ 120 นาที อุณหภูมิในการเชื่อม 370 430 และ 490 องศาเซลเซียส แรงกดที่ 4 MPa ใช้แก๊สอาร์กอนปกคลุม 4 ลิตรต่อนาที ในขณะเชื่อม หลังจากการเชื่อมโดยแพร่ วิเคราะห์ผลการตรวจสอบโครงสร้างทางโลหะวิทยาและการทดสอบสมบัติทางกลของชิ้นงาน จากผลการตรวจสอบพบว่ากรรมวิธีการเชื่อมโดยการแพร่ที่อุณหภูมิ 490 องศาเซลเซียส เวลากดแช่ 120 นาที ให้มีค่าความต้านทานแรงเฉือนมากที่สุดที่ 14.25 MPa ในทางตรงกันข้ามอุณหภูมิ 370 องศาเซลเซียส เวลากดแช่ 60 นาที ผลความต้านทานแรงเฉือนเฉลี่ยต่ำสุดที่ 8.42 MPa และพบว่าค่าความแข็งบริเวณใกล้รอยต่อมีค่าความแข็งสูงสุดอยู่ที่ 135.45 HV ที่อุณหภูมิ 370 องศาเซลเซียส เวลากดแช่ 120 นาที โครงสร้างจุลภาคหลังการเชื่อมพบว่าขนาดของเกรนเกิดการเปลี่ยนแปลงจากโครงสร้างเดิม โดยมีขนาดเกรนที่โตขึ้นจากอุณหภูมิในขณะเชื่อม นอกจากนั้นยังมีการแพร่ของธาตุผสมที่มีความเข้มข้นสูงไปยังบริเวณที่มีความเข้มข้นต่ำด้วยเช่นกัน เมื่อวิเคราะห์เชิงสถิติ พบว่าค่าสัมประสิทธิ์การตัดสินใจร้อยละ 92.95 สามารถควบคุมได้ ในทางตรงกันข้ามร้อยละ 7.05 เกิดจากปัจจัยที่ไม่สามารถควบคุมได้

Article Details

อนุญาตภายใต้เงื่อนไข Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

บทความที่ได้รับการตีพิมพ์ในวารสารฯ ท้ังในรูปแบบของรูปเล่มและอิเล็กทรอนิกส์เป็นลิขสิทธิ์ของวารสารฯ

เอกสารอ้างอิง

G. Mahendran, V. Balasubramanian and T. Senthilvelan, “Influences of diffusion bonding process parameters on bond characteristics of Mg-Cu dissimilar joints,” Transactions of Nonferrous Metals Society of China, vol. 20, no. 6, pp. 997–1005, Jun. 2010, doi: https://doi.org/10.1016/s1003-6326(09)60248-x.

S. Zeng, G. You, F. Yao, J. Luo and X. Tong, “Effect of bonding temperature on the microstructure and mechanical properties of the diffusion-bonded joints of Zr705 alloy,” Materials Science and Engineering: A, vol. 804, pp. 140782, Feb. 2021, doi: https://doi.org/10.1016/j.msea.2021.140782.

F. Zhu, H. Peng, X. Li, and J. Chen, “Dissimilar diffusion bonding behavior of hydrogenated Ti2AlNb-based and Ti-6Al-4V alloys,” Materials & Design, vol. 159, pp. 68–78, Dec. 2018, doi: https://doi.org/10.1016/j.matdes.2018.08.034.

Z. Wang, C. Li, J. Qi, J. Feng and J. Cao, “Characterization of hydrogenated niobium interlayer and its application in TiAl/Ti2AlNb diffusion bonding,” International Journal of Hydrogen Energy, vol. 44, no. 13, pp. 6929–6937, Mar. 2019, doi: https://doi.org/10.1016/j.ijhydene.2019.01.133.

Adhesive Lap Joint Shear Testing of Metals, ASTM D1002, ASTM International, West Conshohocken, 2001.

T. P. Ryan, Modern Engineering Statistics, Hoboken, NJ, USA: Wiley-Interscience, 2007.

G. E. P. Box and N. R. Draper, Empirical Model-Building and Response Surfaces, New York, NY, USA: John Wiley & Sons, 1987.

D. C. Montgomery, Design and Analysis of Experiments, 8th ed. Hoboken, NJ, USA: Wiley Global Education, 2012.

S. Habisch, M. Böhme, S. Peter, T. Grund and P. Mayr, “The Effect of Interlayer Materials on the Joint Properties of Diffusion-Bonded Aluminium and Magnesium,” Metals, vol. 8, no. 2, pp. 138, Feb. 2018, doi: https://doi.org/10.3390/met8020138.

C. Meengam, Y. Dunyakul, D. Maunkhaw and S. Chainarong, “Transient Liquid Phase Bonding of Semi-Solid Metal 7075 Aluminum Alloy using ZA27 Zinc Alloy Interlayer,” Metals, vol. 8, no. 8, pp. 637, Aug. 2018, doi: https://doi.org/10.3390/met8080637.

T. Lin et al., “An investigation on diffusion bonding of Cu/Cu using various grain size of Ni interlayers at low temperature,” Materialia, vol. 14, pp. 100882, Dec. 2020, doi: https://doi.org/10.1016/j.mtla.2020.100882.