Effect of Welding and Heat Treatment on Hardness of High Chromium Cast Iron

Main Article Content

Abstract

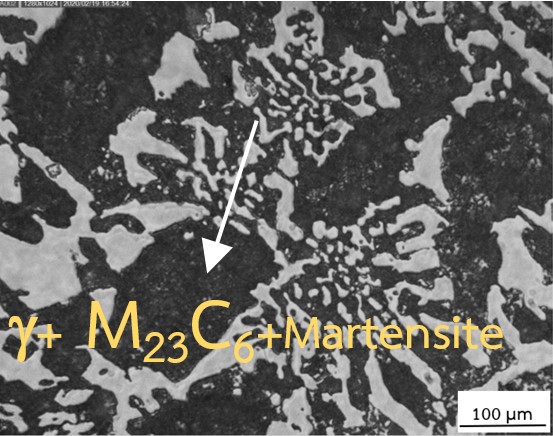

High chromium cast iron is used under conditions of high wear and fractures. This damage affects the cost of production, and repair welding can reduce production costs. Welding requires appropriate welding parameters to achieve functional properties. This research studies the effect of welding, hardening, and tempering on high chromium cast iron hardness as a guide for repair welding. The factors in the study were welding, quenching, and tempering. The specimens were annealed at 950°C for 5 hours. Then, the specimens were welded by Ni 98 welding electrode. After that, the welded specimens were heated to 1,050 °C for 1 hour and 30 minutes, followed by oil quenching. The quenched specimens were tempered at 525 °C for 1 hour. The hardness of specimens was measured using a Rockwell hardness tester at three locations: welded metal heat-affected zone (HAZ), and base metal. Based on statistical data analysis, the results showed that the three processes had no difference in hardness. As a result of the quenching and tempering process, HAZ and base metal zone have higher hardness than welded zone. The base metal zone has a maximum hardness of 63 HRC. Statistical analysis showed a statistically significant difference in hardness values of 0.05. High chromium cast iron welding and heat treatment processing increase hardness in the base metal because of the secondary carbide and martensite. In choosing welding electrode Ni 98, the high nickel in the electrode affects high austenite stability and reduces martensite formation. Therefore, the welded zone hardness is lower than the base metal zone.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Articles published in Journal of Industrial Technology Ubon Ratchathani Rajabhat University both hard copy and electronically are belonged to the Journal.

References

P. Kosasu and S. Inthidech, “Effect of silicon on hardness during heat treatment of 16%Cr cast iron with 2%Mo,” in the 13th Mahasarakham University Research Conference, P. Prathepha, Ed. Mahasarakham, Thailand, Sep. 7-8, 2017, pp. 90-95. (in Thai)

M. Filipovic, Ž. Kamberovic, M. Korac and B. Jordovic, “Effect of Niobium and Vanadium additions on the As-Cast microstructure and properties of hypoeutectic Fe-Cr-C Alloy,” ISIJ International, vol. 53, no. 12, pp. 2160-2166, Jan. 2013.

C. Scandian, C. Boher, J. D. B. de Mello and F. Rézaï-Aria, “Effect of molybdenum and chromium contents in sliding wear of high-chromium white cast iron: The relationship between microstructure and wear,” Wear, vol. 267, no. 1-4, pp. 401-408, Jun. 2009

P. Sokawe, S. Inthidech and K. Sriprateep, “Effect of cryogenic treatment on variation of hardness during subcritical heat treatment of 16 wt% Cr-2 wt% Mo cast iron with Vanadium,” Journal of Science and Technology Mahasarakham University, vol. 33, no. 1, pp. 13-18. Feb. 2014. (in Thai)

S. Inthidech, K. Boonmak, P. Sricharoenchai, N. Sasaguri and Y. Matsubara, “Effect of repeated tempering on hardness and retained austenite of high Chromium cast iron containing Molybdenum,” Materials Transactions, vol. 51, no. 7, pp. 1264-1271, Jun. 2010.

P. Kosasu, S. Inthidech, P. Sricharoenchai and Y. Matsubara, “Effect of Silicon on subcritical heat treatment behavior and wear resistance of 16 wt% Cr Cast Iron with 2 wt% M,” Journal of Metals, Materials and Minerals, vol. 22, no. 2, pp. 89-95, 2012.

R. K. Bhatnagar and G. Gupta, “A review on weldability of cast iron,” International Journal of Scientific & Engineering Research, vol. 7, no. 5, pp. 126-131, May. 2016.

T. Teker and E. M. Karakurt, “Friction welding of high chromium white cast iron and AISI1030 steel couple with nickel interlayer,” in UDCS' Fourth International Iron and Steel Symposium, M. Yasar, Ed. Karabuk, Turkey, Apr. 4-6, 2019, pp. 26-28.

P. Batkhuu, G. Omoontsoo, B. Lygdenov, and A. Guriev, “Laser processing of high chromium white iron,” Journal of physics: Conference series, vol. 2131, no. 5, Dec. 2021.

A. Cruz-Crespo, R. Fernández-Fuentes, A. V. Ferraressi, R. A. Gonçalves and A. Scotti, “Microstructure and abrasion resistance of Fe-Cr-C and Fe-Cr-C-Nb hardfacing alloys deposited by S-FCAW and cold solid wires,” Soldagem & Inspeção, vol. 21, no. 3, pp. 342–353, Sep. 2016.

H. Wang and S. Yu, “Influence of heat treatment on microstructure and sliding wear resistance of high chromium cast iron electroslag hardfacing layer,” Surface and Coatings Technology, vol. 319, pp. 182–190, Jun. 2017.

A O’Brien and C. Guzman, Welding Handbook, Volume 4: Material and Application, Part 1, 9th ed. Miami, FL, USA: American Welding Society, 2011.

M. Sangsuriyan and P. Surin, “Study of microstructure and creep resistance of electrical welding process in spheroidal graphite cast-iron,” EAU Heritage Journal Science and Technology, vol. 13, no. 1, pp. 197-208. Apr. 2019. (in Thai)

S. Noyming, W. Homjabok and N. Thammachot, “Analysis of factors affecting the case depth hardness of hardened surface in low carbon steel by design of experiments using limestone as an energizer in pack carburizing process,” Journal of Industrial Technology Ubon Ratchathani Rajabhat University, vol. 11, no. 2, pp. 67-80. Dec. 2020. (in Thai)

E. S. V. Marques, F. J. G. Silva, O. C. Paiva and A. B. Pereira, “Improving the mechanical strength of ductile cast iron welded joints using different heat treatments,” Materials, vol. 12, no. 14, Jul. 2019, Art. no. 2263.

Z. Guo, F. Xiao, S. Lu, H. Li and B. Liao, “Effects of heat-treatment on the microstructure and wear resistance of a High-chromium cast iron for rolls,” Advances in Materials Science and Engineering, vol. 2016, Oct. 2016, Art. no. 9807685.

S. Inthidech, P. Sricharoenchai and Y. Matsubara, “Effect of alloying elements on heat treatment behavior of hypoeutectic high Chromium cast iron,” Materials Transactions, vol. 47, no. 1, pp. 72–81, Jan. 2006.