Influence of rapid annealing temperature on the mechanical properties of TiCN thin film as prepared by cathodic arc

DOI:

https://doi.org/10.55674/cs.v17i2.260691Keywords:

TiCN, Cathodic arc deposition, Thin films, RTA, NanoindentationAbstract

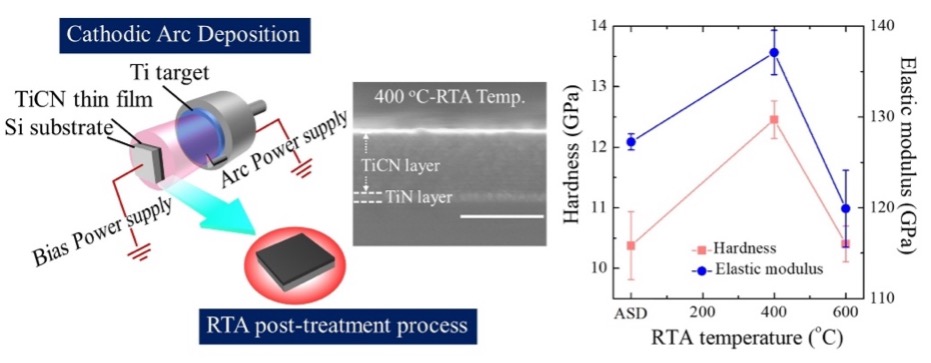

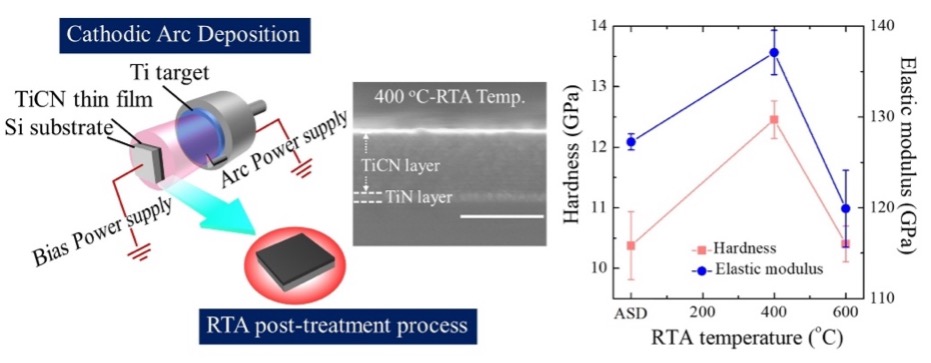

In this study, titanium carbonitride (TiCN) thin films were deposited using cathodic arc deposition techniques. The as-deposited TiCN thin films were subsequently subjected to annealing treatment by rapid thermal annealing (RTA) technique at a temperature range from 400 to 600 °C. The effect of RTA temperature on the crystallinity, morphology, chemical composition, and mechanical properties of the TiCN thin films was investigated. The grazing incident X-ray diffraction (GIXRD) analysis confirmed the presence of a dominant face-centered cubic TiCN phase. Cross-sectional field-emission scanning electron microscopy (FE-SEM) images revealed a compact and homogeneous morphology, which became more pronounced with increasing RTA temperatures. The X-ray photoelectron spectroscopy (XPS) indicated the atomic concentration of the primary element (Ti, C, and N) remained relatively stable throughout the annealing process. Furthermore, the hardness of the TiCN thin films improved at 400 °C-RTA temperature.

GRAPHICAL ABSTRACT

HIGHLIGHTS

- Crystalline TiCN thin films were successfully deposited via cathodic arc deposition.

- RTA treatment improved the TiCN thin film, resulting in a highly compact morphology.

- The harness of TiCN showed enhancement at 400 oC-RTA temperature.

References

S. Jena, A. Madhuri, M. Gupta, B.P. Swain, Comparative assessment and experimental analysis of atomic coordination and mechanical properties of sputter deposited Ti-rich TiN, TiC, and TiCN thin films, J. Alloys Compd. 1002 (2024) 175217.10.1016/j.jallcom.2024.175217

S.E. Shakib, A. Babakhani, M.K.Torbati, Nanomechanical assessment of tribological behavior of TiN/TiCN multi-layer hard coatings deposited by physical vapor deposition, J. Mater. Res. Technol. 25 (2023) 1344 – 1354.10.1016/j.jmrt.2023.05.243

Z. Su, X. Jie, W. Li, Z. Liao, Y. Li, W. Zhu, Effect of C2H2 flow rate and a Ti/TiN/TiCN interlayer on the structure, mechanical and tribological properties of a-C:H films deposited using a hybrid PVD/PECVD process with an anode-layer ion source, Vacuum. 209 (2023) 111753.10.1016/j.vacuum.2022.111753

G. Xian, J. Xiong, H. Fan, F. Jiang, H. Zhao, L. Xian, Z. Qin, Mechanical and wear properties of TiN films on differently pretreated TiCN-based cermets, Appl. Surf. Sci. 570 (2021) 151180.10.1016/j.apsusc.2021.151180

M.B. Hassine, H.O. Andrén, A.H.S. Iyer, O. Bäcke, D. Stiens, W. Janssen, J. Kümmel, M. Halvarsson, Growth of a hard, novel CVD multilayer coating: Ti(C,N) on (Ti,Al)N on TiN, Int. J. Refract. Met. Hard Mater. 127 (2025) 106966.10.1016/j.ijrmhm.2024.106966

G. Baravian, G. Sultan, E. Damond, H. Detour, C. Hayaud, P. Jacquot, Optical emission spectroscopy of active species in a TiCN PVD arc discharge, Surf. Coat. Technol. 76–77 (1995) 687-693.10.1016/0257-8972(96)80007-7

T. Polcar, R. Novák, P. Široký, The tribological characteristics of TiCN coating at elevated temperatures, Wear. 260(1–2) (2006) 40-49.10.1016/j.wear.2004.12.031

Z. Zeng, H. Xiao, X. Jie, Y. Zhang, Friction and wear behaviors of TiCN coating based on electrical discharge coating, Trans. Nonferrous Met. Soc. China. 25(11) (2015) 3716-3722.10.1016/S1003-6326(15)64013-4

N.S. Mansoor, A. Fattah-alhosseini, H. Elmkhah, A. Shishehian, Comparison of the mechanical properties and electrochemical behavior of TiN and CrN single-layer and CrN/TiN multi-layer coatings deposited by PVD method on a dental alloy, Mater. Res. Express. 6 (2019) 126433.10.1088/2053-1591/ab640d

N.S. Mansoor, A. Fattah-alhosseini, H. Elmkhah, A. Shishehian, Electrochemical behavior of TiN, CrN and TiN/CrN nanostructured coatings on the nickel-chromium alloy used in dental fixed prosthesis, J. Asian Ceram. Soc. 8(3) (2020) 694–710.10.1080/21870764.2020.1776915

R.A. Antunes, A.C.D. Rodas, N.B. Lima, O.Z. Higa, I. Costa, Study of the corrosion resistance and in vitro biocompatibility of PVD TiCN-coated AISI 316L austenitic stainless steel for orthopedic applications, Surf. Coat. Technol. 205(7) (2010) 2074 – 2081.10.1016/j.surfcoat.2010.08.101

J.C. Sánchez-López, M.D. Abad, I. Carvalho, R. Escobar Galindo, N. Benito, S. Ribeiro, M. Henriques, A. Cavaleiro, S. Carvalho, Influence of silver content on the tribomechanical behavior on Ag-TiCN bioactive coatings, Surf. Coat. Technol. 206(8–9) (2012) 2192 – 2198.10.1016/j.surfcoat.2011.09.059

R. Chen, J.P. Tu, D.G. Liu, Y.J. Mai, C.D. Gu, Microstructure, mechanical and tribological properties of TiCN nanocomposite films deposited by DC magnetron sputtering, Surf. Coat. Technol. 205(21–22) (2011) 5228 – 5234.10.1016/j.surfcoat.2011.05.034

T. Kimura, R. Yoshida, K. Azuma, S. Nakao, Preparation of titanium carbon nitride films by reactive high power pulsed sputtering Penning discharges, Vacuum. 157 (2018) 192 – 201.10.1016/j.vacuum.2018.08.043

N. Saoula, N. Madaoui, R. Tadjine, R.M. Erasmus, S. Shrivastava, J.D. Comins, Influence of substrate bias on the structure and properties of TiCN films deposited by radio-frequency magnetron sputtering, Thin Solid Films. 616 (2016) 521 – 529.10.1016/j.tsf.2016.08.047

M.R. Figueiredo, J. Neidhardt, R. Kaindl, A. Reiter, R. Tessadri, C. Mitterer, Formation Mechanisms of Low-Friction Tribo-layers on Arc-Evaporated TiC1−xNx Hard Coatings, Wear. 265 (2008) 525 – 532.10.1016/j.wear.2007.11.020

L. Escobar-Alarcon, V. Medina, E. Camps, S. Romero, M. Fernandez, D. Solis-Casados, Microstructural characterization of Ti–C–N thin films prepared by reactive crossed beam pulsed laser deposition, Appl. Surf. Sci. 257(21) (2011) 9033 – 9037.10.1016/j.apsusc.2011.05.094

E. Bemporad, C. Pecchio, S.D. Rossi, F. Carassiti, Characterization and hardness modelling of alternate TIN/TICN multilayer cathodic arc PVD coating on tool steel, Surf. Coat. Technol. 146–147 (2001) 363 – 370.10.1016/S0257-8972(01)01416-5

T. Bakalova, L. Svobodová, N. Petkov, H. Bahchedzhiev, M. Švec, P. Kejzlar, P. Šutta, K. Daďourek, The effect of the process gas mixture ratio on the structure and composition of TiC and TiCN thin layers prepared by cathodic arc deposition on tool steel, J. Manuf. Process. 93 (2023) 90 – 100.10.1016/j.jmapro.2023.02.067

Q. Chen, D. Liang, E. Zhang, L. Yang, Q. Zhou, B. Huang, S. Han, Influence of C2H2/N2 flow ratio on the microstructure, mechanical properties, and electrochemical behavior of TiCN composite coatings, Vacuum. 216 (2023) 112349.10.1016/j.vacuum.2023.112349

H. Nakajima, W. Phae-ngam, S. Chaiyakun, V. Tapanwong, T. Wongpinij, T. Lertvanithphol, M. Horprathum, Spectroscopic analysis of color origins in titanium-based thin films deposited by cathodic arc deposition, Appl. Surf. Sci. 673 (2024) 160900.10.1016/j.apsusc.2024.160900

D. Zhu, S. Zhao, C. Zheng, D. Chen, Z. He, Annealing effect of thermal spike in MgO thin film prepared by cathodic vacuum arc deposition, Mater. Chem. Phys. 143(1) (2013) 209-212.10.1016/j.matchemphys.2013.08.053.

K. Jokar, H. Elmkhah, A. Fattah-alhosseini, K. Babaei, A. Zolriasatein, Comparison of the wear and corrosion behavior between CrN and AlCrN coatings deposited by Arc-PVD method, Mater. Res. Express. 6 (2019) 116426.10.1088/2053-1591/ab4645

E. Lotfi-khojasteh, M. Sahebazamani, H. Elmkhah, M. Nouri, O. Imantalab, A. Fattah-alhosseini, A study of the electrochemical and tribological properties of TiN/CrN nano-layer coating deposited on carburized-H13 hot-work steel by Arc-PVD technique. J. Asian Ceram. Soc. 9(1) (2021) 270–282.10.1080/21870764.2020.1863577

H. Elmkhah, F. Attarzadeh, A. Fattah-alhosseini, K.H. Kim, Microstructural and electrochemical comparison between TiN coatings deposited through HIPIMS and DCMS techniques, J. Alloys Compd. 735 (2018), 422-429.10.1016/j.jallcom.2017.11.162

E. Kaya, M. Ulutan, Tribomechanical and microstructural properties of cathodic arc-deposited ternary nitride coatings, Ceram. Int. 48(15) (2022) 21305 – 21316.10.1016/j.ceramint.2022.04.097

O. Singh, H.K. Malik, R.P. Dahiya, P. Kumar, Influence of negative bias voltage on structural and mechanical properties of nanocrystalline TiNx thin films treated in hot cathode arc discharge plasma system, Ceram. Int. 42(16) (2016) 18019 – 18024.10.1016/j.ceramint.2016.08.032

S.K. Kim, V.V. Le, Deposition of nanolayered CrN/AlBN thin films by cathodic arc deposition: Influence of cathode arc current and bias voltage on the mechanical properties, Surf. Coat. Technol. 204(24) (2010) 3941 – 3946.10.1016/j.surfcoat.2009.12.011

M. Kuczyk, T. Krülle, M. Zawischa, J. Kaspar, O. Zimmer, M. Leonhardt, C. Leyens, M. Zimmermann, Microstructure and mechanical properties of high entropy alloy nitride coatings deposited via direct current cathodic vacuum arc deposition, Surf. Coat. Technol. 448 (2022) 128916.10.1016/j.surfcoat.2022.128916

R. Akhter, A. Bendavid, P. Munroe, Tailoring the scratch adhesion strength and wear performance of TiNiN nanocomposite coatings by optimising substrate bias voltage during cathodic arc evaporation, Surf. Coat. Technol. 445 (2022) 128707.10.1016/j.surfcoat.2022.128707

H. Curtins, PLATIT: a new industrial approach to cathodic arc coating technology, Surf. Coat. Technol. 76–77 (1995) 632-639.10.1016/0257-8972(95)02552-9

P.H. Wu, I.K. Lin, H.Y. Yan, K.S. Ou, K.S. Chen, X. Zhang, Mechanical property characterization of sputtered and plasma enhanced chemical deposition (PECVD) silicon nitride films after rapid thermal annealing, Sens. Actuators A: Phys. 168(1) (2011) 117 – 126.10.1016/j.sna.2011.03.043

Z.H. Huang, B. Yang, C.S. Liu, L.P. Guo, X.J. Fan, D.J. Fu, Effect of annealing on the composition, structure and mechanical properties of carbon nitride films deposited by middle-frequency magnetron sputtering, Mater. Lett. 61(16) (2007) 3443 – 3445.10.1016/j.matlet.2006.11.127

Z. Song, Y. Liu, S. Jiang, X. Jiang, D.G. Piliptsou, A.V. Rogachev, Effects of post-deposition annealing on structure and mechanical properties of multilayer Ti/DLC films, Diam. Relat. Mater. 147 (2024) 111340.10.1016/j.diamond.2024.111340

M.R. Pallavolu, S.W. Joo, C. Park, Significance of rapid thermal annealing and its ramp rate effect on the properties of monoclinic CTS thin films, Micro and Nanostructures. 166 (2022) 207234.10.1016/j.micrna.2022.207234.

H. Nakajima, S. Chaichuay, P. Sudmuang, S. Rattanasuporn, W. Jenpiyapong, R. Supruangnet, N. Chanlek, P. Songsiriritthigul, Commissioning of the soft x-ray undulator beamline at the Siam Photon Laboratory, AIP Conf. Proc. 1741(1) (2016) 020040. 10.1063/1.4952819

H. Li, S. Rong, P. Sun, Q. Wang, Microstructure, Residual Stress, Corrosion and Wear Resistance of Vacuum Annealed TiCN/TiN/Ti Films Deposited on AZ31, Metals. 7(1) (2017) met7010005.10.3390/met7

T.H. Fang, S.R. Jian, D.S. Chuu, Nanomechanical properties of TiC, TiN and TiCN thin films using scanning probe microscopy and nanoindentation, Appl. Surf. Sci. 228 (1–4) (2004) 365-372.10.1016/j.apsusc.2004.01.053.

Y. Sun, C. Lu, H. Yu, A. K. Tieu, L. Su, Y. Zhao, H. Zhu, C. Kong, Nanomechanical properties of TiCN and TiCN/Ti coatings on Ti prepared by Filtered Arc Deposition, Mater. Sci. Eng. A. 625 (2015) 56-64,10.1016/j.msea.2014.11.093.

Downloads

Published

How to Cite

Issue

Section

Categories

License

Copyright (c) 2025 Creative Science

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.