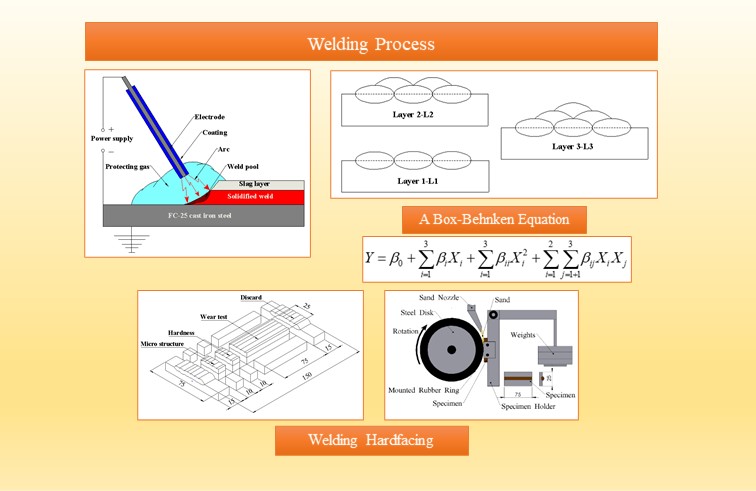

The The optimization of welding hardfacing on wear resistance of FC-25 grey cast iron steel substrate by response surface methodology (RSM)

DOI:

https://doi.org/10.55674/snrujst.v14i2.245154Keywords:

Response surface, Welding hardfacing, FC-25 grey cast ironAbstract

This paper aimed to identify the optimal conditions for welding hardfacing by applying the Response Surface Methodology (RSM). The welding heat input, electrode type, and hardfacing layer on wear resistance of welding hardfacing were all optimized using the Box-Behnken experimental design. The findings revealed that these three variables had an impact on the volume loss of welding hardfacing. Because of the high coefficient of determination, the experimental data obtained were to a quadratic equation (96.90%). The ideal condition was determined using a 3D response surface plot and a contour map produced from mathematical models. The following were the ideal welding conditions: With a welding heat input of 1.58 J, a filler metal type of DFA2-600-B, and a third layer of hardfacing, the lower volume loss of the weld was 1.29 mm3.

References

C. Felix, G.D.L. Hijes, JR. Cartagena, Maintenance strategy based on a multicriteria classification of equipment, Reliable. Eng. Syst. Safe. 91(4) (2006) 444 – 451.

C.S. Sharma, K. Purohit, Design of machine elements, Prentice-Hall of India, 2003.

G.S. Sidhu, S.S. Chatha, Role of shielded metal arc welding consumables on pipe weld joint, Int. j. emerge. technol. adv. Eng. 12(4) (2012) 746 – 750.

J.W. Sowards, J.C. Lippold, D.W. Dickinson, A.J. Ramirez, Characterization of welding fume from SMAW electrodes-Part I, Weld J. 87(4) (2008) 106 – 112.

S.J.S. Chelladura, K. Muragun, A.P. Ray, M. Upadhyaya, V. Narasimharaj, S. Gnanasekaran, Opimization of process parameters using response surface methodology, A review, Materials Today: Proceedings. 37 (2021) 1301 – 1304.

H. Abed, F.M. Ghaini, H.R. Shahverdi, Characterization of Fe49Cr18Mo7B16C4Nb6 high entropy hardfacing layers produced by gas tungsten arc welding (GTAW) process, Surf. Coat. Technol. 352 (2018) 360 – 369.

A. Klimpel, L.A. Dobrzański, A. Lisiecki, D. Janicki, The study of properties of Ni–W2C and Co–W2C powders thermal sprayed deposits, J. Mater. Process. Technol. 164 (2005) 1068 – 1073.

S. Prasomthong, N. Namkaew, The influence of adding aluminium welding wire on mechanical properties and chemical composition of the welding hardfacing welded low carbon steel by gas tungsten arc welding process, J. Ind. Tech. 17(1) (2019) 27 – 36.

S.K. Shihab, Optimization of WEDM process parameters for machining of friction-stir-welded 5754 aluminum alloy using Box–Behnken design of RSM, Arab J Sci Eng. 43(9) (2018) 5017 – 5027.

M.P. Jenarthanan, R. Jeyapaul, Optimisation of machining parameters on milling of GFRP composites by desirability function analysis using Taguchi method, Int. j. Eng. Sci. Technol. 5(4) (2013) 22 – 36.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 SNRU Journal of Science and Technology

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.