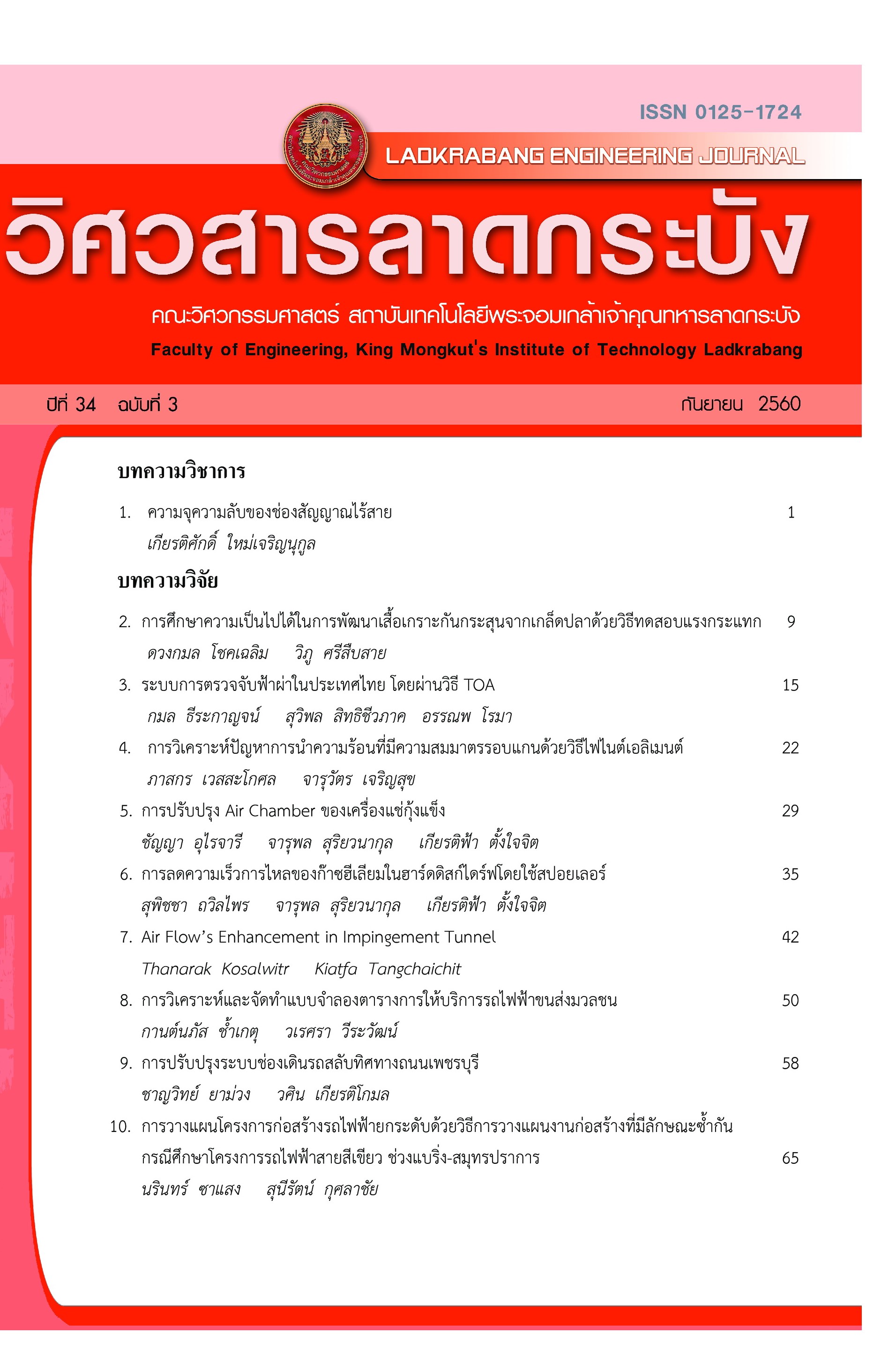

Air Flow’s Enhancement in Impingement Tunnel

Keywords:

Impingement freezer, Computational Fluid Dynamic (CFD), SST, Pressured chamber, Impingement nozzle, Exit velocity, Vortexes.Abstract

The air impingement technology has been used in frozen food industry for decades to achieve rapid freezing that can freeze the food with better texture than conventional freezing. In the freezing process the determined freezing time must be selected from the longest time that frozen food temperature is reached -18°C. To minimize the freezing time variation from different locations along the conveyor belt’s width, the pressured chamber was investigated using computational fluid dynamics. The SST, k-ω turbulence model was used in this study. Changing the geometry in the pressured chamber with baffle plates impacted the exit velocity from impingement nozzles, which can deliver better average exit velocity and variation. The mixed model of existing with 2 of P532.5 for 3 chambers impingement tunnel freezer gives a 22.2% better minimum exit velocity than the existing model, and a variation of exit velocity 2.53 times better than the existing model.

References

[2] A. Delgado, L. Zheng, D. W. Sun, “Influence of ultrasound on freezing rate of immersion-frozen apples”, Food and Bioprocess Technology, Vol. 2, 263-270, 2009.

[3] F. Streit, G. Corrieu, B. C. eal, “Effect of centrifugation conditions on the cryotolerance of lactobacillus bulgaricus cfl1”, Food and Bioprocess Technology, Vol. 3, 36-42, 2010.

[4] V. Soto, R. Borquez.,“Impinge ment jet freezing of bio material”, Food Control, Vol. 12, 515-522, 2001.

[5] T. H. Jackson, A. Ungan, J. K. Critser, and D. Y. Gao, “Novel microwave technology for cryo- preservation of biomaterials by suppression of apparent ice formation”, Cryobiology, Vol. 34, 363-372, 1997.

[6] T. Inada, X. Zhang, A. Yabe, and Y. Kozawa, “Active control of phase change from super cooled water to ice by ultrasonic vibration 1. Control of freezing temperature”, International Journal of Heat and Mass Transfer, Vol. 44, 4523-4531. 2001.

[7] M. Saclier, R. Peczalski, J. Andrieu, “Effect of ultra sonically induced nucleation on ice crystals’ size and shape during freezing in vials”, Chemical Engineering Science, Vol. 65, 3064-3071, 2010.

[8] R. Chow, R. Blindt, R. Chivers, and M. Povey, “The sono crystallisation of ice in sucrose solutions:primary & secondary nucleation”, Ultrasonics, Vol. 41,595-604, 2003.

[9] R. Chow, R. Blindt, A. Kamp, P. Grocutt, and R. Chivers, “The microscopic visualisation of the sonocrystallisation of ice using a novel ultrasonic cold stage”, Ultrasonics Sonochemistry, Vol. 11, 245-250, 2004.

[10] G. Ruecroft, D. Hipkiss, T. Ly, N. Maxted, and P. W. Cains, “Sonocrystallization: the use of ultrasound for improved industrial crystallization”, Organic Process Research & Development, Vol. 9, 923-932, 2005.

[11] L. Zheng, D. W. Sun, “Ultra sonic assistance of food freezing”, .In D.-W. Sun (Ed.), Emerging technologies for food processing.Amsterdam;London: Elsevier Academic Press, 2005.

[12] Yang Geunyoung, Choi Man soo, Sik Lee Joon, “An experi mental study of slot jet impinge ment cooling on concave surface: effects of the nozzle configuration and curvature”, International Journal of Heat Transfer, Vol. 42, 2199-2209, 1999.

[13] Salvadori O. Viviana, Mascher oni H. Rodolfo, “Analysis of impingement freezers perfor mance”, Journal of Food Engineering, Vol.54, 133–140, 2002.

[14] Anderson A. Brent, Paul Singh R., “Effective heat transfer coefficient measurement during air impingement thawing using an inverse method”, Inter national Journal of Refrig eration, Vol. 29, 281-293, 2006.

[15] Huan Zhongjie, He a Shaoshu, Ma Yitai, “Numerical simulation and analysis for quick-frozen food processing”, Journal of Food Engineering, Vol. 60, 267-273, 2003.

[16] Arnab Sarkar, R.Paul Singh, “Air Impingement technology for food processing: visual ization studies”, Lebensm.Wiss. u.Technol, Vol. 37, 873-879, 2004.

[17] A. Sarkar, N. Nitin, M. V. Karwe, and R. P. Singh, “Fluid Flow and Heat Transfer in Air Jet Impingement in Food Processing”, Journal of food science, Vol. 69, No. 4, 113-122, 2004.

[18] N. K. Chougule, G. V. Parishwad, P. R. Gore, S. Pagnis, and S. N. Sapali, “CFD Analysis of Multi-jet Air Impingement on Flat Plate”, Proceeding of the world Congress on Engineering, Vol. 3, ISSN: 2078-0966, 2011.

[19] B. Dahbia, M. Amina, in the Ninth International Conference on Computational Fluid Dynamics (ICCFD9) Istanbul, Turkey, July 11-15, 2016.

[20] T. Kosalwitr, K. Tangchaichit, “Freezing time of the impingement tunnel freezer enhancement”, KKU ENGI NEERING JOURNAL, Vol. 43, No. 3, 409-411, 2016.

[21] D. Prashata, D. Sandip, “Effect of baffle size, perforate and orientation on internal heat transfer enhancement”, Inter national Journal of Heat and Mass Transfer, Vol. 41, 3005-3013, 1998.

[22] E.Mehmet, C. Sinan, Z. Muammer, “Experimental Investigation of Heat transfer in a Rectangular Channel with Perforate Ribs”, The Online Journal of Science and Technology, Vol. 5, Issue 3, 37-44, 2015.

Downloads

Published

How to Cite

Issue

Section

License

The published articles are copyrighted by the School of Engineering, King Mongkut's Institute of Technology Ladkrabang.

The statements contained in each article in this academic journal are the personal opinions of each author and are not related to King Mongkut's Institute of Technology Ladkrabang and other faculty members in the institute.

Responsibility for all elements of each article belongs to each author; If there are any mistakes, each author is solely responsible for his own articles.