Thermal Evaluation of Solar Dryer’s Curve-Front utilized Heat Transfer Analysis

DOI:

https://doi.org/10.69650/rast.2024.257468Keywords:

Renewable Energy , Natural Convection, Laminar Flow, Solar Radiation , Heat Transfer CoefficientsAbstract

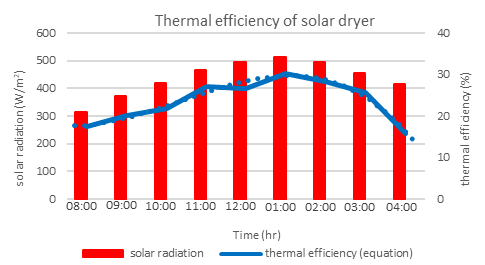

The sun is most sustainable renewable energy, environmentally friendly and utilized for preservation of food and agricultural crops. The main objective of this experiment research work has focused on using renewable energy for evaporated moisture of foods fruit vegetables and herbs by drying system. The heat transfer equation are analyzed to effectively harness the temperature from the sun. Experimental data obtained were used to evaluate the properties of dry air on boundary region condition. Initial, testing was carried out under without load condition, and the result shows that the ambient and dryer’s internal temperature range between 29.3-40.2˚C and 37.4-60.3 ˚C, respectively, in Thailand a latitude of 14°0'48.46" North and longitude of 100°31'49.76" East (recorded average solar radiations and temperature on January 2023 - June 2024), average solar radiations range between 312 W/m2 and 513 W/m2. The indirect natural convection was design and calculated energy base on average temperature not higher than 55˚C, utilized sun daylight at 08:00 a.m. to 04:00 p.m. local time and clear sky or partially cloudy. Second, determination of design parameters; heat energy equation and steam table analysis. Final, utilization of the design under local time, solar radiation and the climatic local conditions and test with ginger slices (represent product in order to examine weight loss). The solar dryer’s curve front shape conduced on without load showed the heat transfer coefficient natural convections range between 3.7 and 4.5 W/m2 ˚C, the energy of dry air analysis range between 54.7 and 155.2 J/s and performance of drying rate range between 0.06 and 0.82 g/s, under increasing and decreasing trends of solar radiations from the time, date and climatic local region condition.

References

Maundu, N. M., Kosgei, S. K. And Nakajo, Y., Design and Analysis of Solar Dryer for Mid-Latitude Region. Energy Procedia. 100(2016) 98 – 110, doi: https://doi.org/10.1016/j.egypro.2016.10.145.

Çengel, Y. A. Heat transfer; A Practical Approach. 2nd edn., McGraw-Hill, 2002.

Toledo, R. T. Fundamentals of Food Process Engineering. 2nd edn., Aspen Publishers, 1999.

Olaoye, O. S. and Ogunleye, A. J., Experimental Study of Drying Parameters of Ginger at Different Temperature and Moisture Content. European Journal of Engineering and Research and Science. 3(9) 2018.

Adelaja, A. O. and Babatope, B. I., Analysis and Testing of a Natural Convection Solar Dryer for the Tropics. Journal of Energy. (2013), doi: https://doi.org/10.1155/2013/479894.

Mehmet, D., Erdem, A. and Ebru, K. A., Numerical and experimental analysis of heat and mass transfer in the drying process of solar drying system. Engineering Science and Technology, an International Journal. 24(1) (2021) 236-246, doi: https://doi.org/10.1016/j.jestch.2020.10.003.

Houghton E. L., Carpenter, P. W., Steven H., Collicott, S. H. and Daniel, V. Aerodynamics for Engineering Students. 6th edn., Butterworth-Heinemann, 2013.

Oko C. O. C. and Diemuodeke, E. O., Analysis of air-conditioning and drying processes using spreadsheet add-in for psychrometric data. Journal of Engineering Science and Technology Review. 3(1) (2010) 7-13, doi: https://doi.org/DOI:%2010.25103/jestr.031.02.

Ji, Y. Y., Hee, J. K., Eun, J. W. and Chan, J. P., On Solar Energy Utilization for Drying Technology. International Journal of Environmental Science and Development. 8(4) 2017, 305-311, doi: https://doi.org/10.18178/ijesd.2017.8.4.968.

Ekechukwu, O. V., Review of solar-energy drying systems I: an overview of drying principles and theory. Energy Conversion and Management. 40(6) (1999) 593-613, doi: https://doi.org/10.1016/S0196-8904(98)00092-2.

Mujumdar, A. S. Handbook of Industrial drying. 4th edn., CRC Press; Taylor and Francis Group, 2007, doi: https://doi.org/10.1201/b17208.

Eshetu, G., Mulugeta, A. D., Nigus, G. H., Solomon, W. F., Petros, D. and Maarten, V., Importance of integrated CFD and product quality modeling of solar dryers for fruits and vegetables: A review. Solar Energy. 220 (2021) 88-110, doi: https://doi.org/10.1016/j.solener.2021.03.049.

Hussein, J. B., Hassan, M. A., Kareem, S. A, Filli, K.B.Design, Construction and Testing of a Hybrid

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 School of Renewable Energy and Smart Grid Technology (SGtech)

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

All copyrights of the above manuscript, including rights to publish in any media, are transferred to the SGtech.

The authors retain the following rights;

1. All proprietary rights other than copyright.

2. Re-use of all or part of the above manuscript in their work.

3. Reproduction of the above manuscript for author’s personal use or for company/institution use provided that

(a) prior permission of SGtech is obtained,

(b) the source and SGtech copyright notice are indicated, and

(c) the copies are not offered for sale.