Variations in acoustic emission characteristics across different deformation stages of various materials

Main Article Content

Abstract

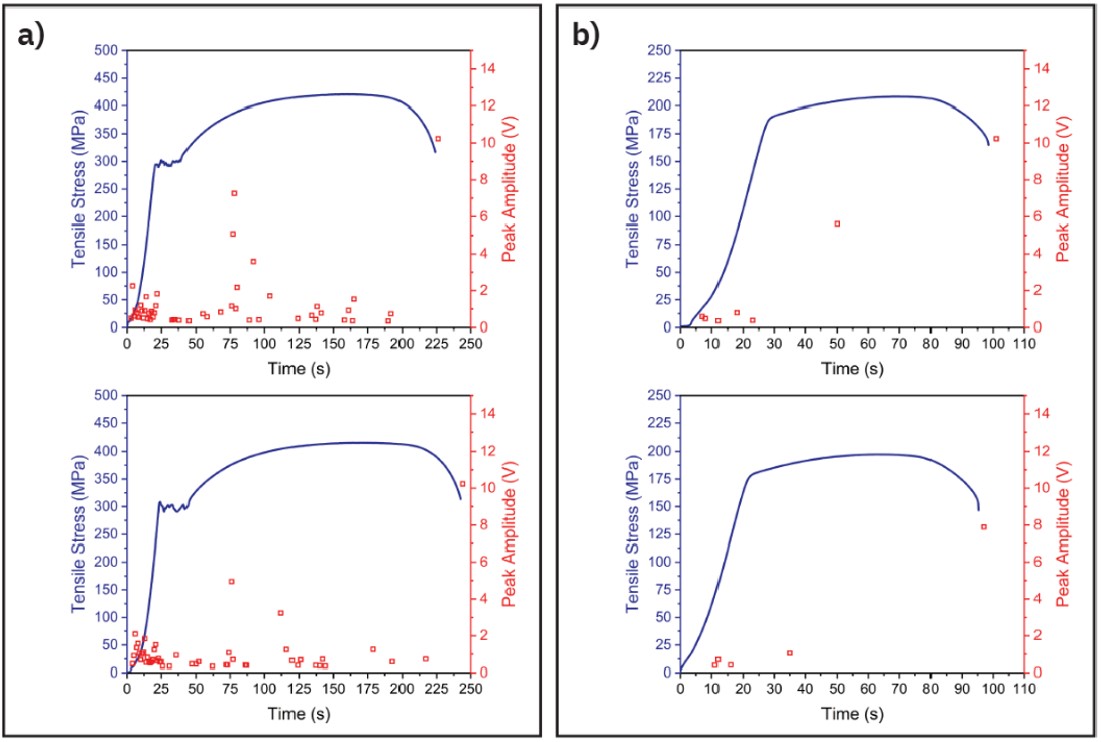

Integration of acoustic emission (AE) monitoring with traditional mechanical testing presents an attractive methodology for the prediction and assessment of material failure processes. While AE monitoring during mechanical testing has been extensively applied to study deformation and fracture in individual materials, conducting a comparative analysis across various monolithic materials using a single AE system provides valuable insights. This approach helps identify material-specific signal characteristics and behaviors that are essential for predicting failure in complex, multi-material structures. In this study, uniaxial testing with AE monitoring was conducted for evaluating failure behaviors of four different materials, namely low-carbon steel, aluminum alloy, acrylic and white Portland cement (WPC). The AE patterns obtained from tensile testing of ductile metallic materials, low‑carbon steel and aluminum alloy clearly indicated the regions of elastic, plastic and fracture by difference of peak amplitude intensity of AE signals. AE signals obtained from brittle materials, PMMA acrylic and WPC specimens showed fluctuated AE peak amplitude intensities throughout the linear deformation region until specimen fracture. The AE signals and their corresponding Fast Fourier Transform spectra provide data indicating failure of different materials, as well as failure behaviors, i.e., elastic, plastic and fracture, of ductile metallic materials.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

Calabrese L, Proverbio E. A review on the applications of acoustic emission technique in the study of stress corrosion cracking. Corros Mater Degrad. 2020;2(1):1-30.

Kongpuang M, Culwick R, Cheputeh N, Marsh A, Jantara Junior VL, Vallely P, et al. Quantitative analysis of the structural health of railway turnouts using the acoustic emission technique. Insight Non-Destr Test Cond Monit. 2022;64(7):398-403.

Topolář L, Kocáb D, Pazdera L, Vymazal T. Analysis of acoustic emission signals recorded during freeze-thaw cycling of concrete. Materials. 2021;14(5):1230.

Shanbhag VV, Pereira PM, Rolfe FB, Arunachalam N. Time series analysis of tool wear in sheet metal stamping using acoustic emission. J Phys: Conf Ser. 2017;896:012030.

Skåre T, Krantz F. Wear and frictional behaviour of high strength steel in stamping monitored by acoustic emission technique. Wear. 2003;255(7-12):1471-9.

Laonapakul T, Nimkerdphol AR, Otsuka Y, Mutoh Y. Failure behavior of plasma-sprayed HAp coating on commercially pure titanium substrate in simulated body fluid (SBF) under bending load. J Mech Behav Biomed Mater. 2012;15:153-66.

Jayakumar T, Mukhopadhyay CK, Venugopal S, Mannan SL, Raj B. A review of the application of acoustic emission techniques for monitoring forming and grinding processes. J Mater Process Technol. 2005;159(1):48-61.

Abo-El-Ezz AE. Acoustic emission detection of micro-cracks initiation and growth in polymeric materials. In: Hassan MF, Megahed SM, editors. Current Advances in Mechanical Design and Production VII. Oxford: Elsevier; 2000. p. 253-60.

Guo TY, Wong LNY. Cracking mechanisms of a medium-grained granite under mixed-mode I-II loading illuminated by acoustic emission. Int J Rock Mech Min Sci. 2021;145:104852.

Ríos-Soberanis CR, Wakayama S, Sakai T, Cervantes-Uc JM, May-Pat A. Evaluation of mechanical behaviour of bone cements by using acoustic emission technique. Adv Mater Res. 2014;856:246-50.

Roques A, Browne M, Thompson J, Rowland C, Taylor A. Investigation of fatigue crack growth in acrylic bone cement using the acoustic emission technique. Biomaterials. 2004;25(5):769-78.

Xu Y, Mellor BG. Characterization of acoustic emission signals from particulate filled thermoset and thermoplastic polymeric coatings in four point bend tests. Mater Lett. 2011;65(23-24):3609-11.

Loanapakul T, Otsuka Y, Mutoh Y. Fatigue and acoustic emission behavior of plasma sprayed HAp top coat and HAp/Ti bond coat with HAp top coat on commercially pure titanium. Key Eng Mater. 2011;452-453:857-60.

Laonapakul T, Otsuka Y, Nimkerdphol AR, Mutoh Y. Acoustic emission and fatigue damage induced in plasma-sprayed hydroxyapatite coating layers. J Mech Behav Biomed Mater. 2012;8:123-33.

Kongpuang M. Reliability-base monitoring and maintenance of urban railway turnout using acoustic emission [dissertation]. Birmingham: University of Birmingham; 2022.

Zhao Y, Zhang Y, Xu J, Zhang M, Yu P, Zhao Q. Frequency domain analysis of mechanical properties and failure modes of PVDF at high strain rate. Constr Build Mater. 2020;235:117506.

Vetrone J, Obregon JE, Indacochea EJ, Ozevin D. The characterization of deformation stage of metals using acoustic emission combined with nonlinear ultrasonics. Measurement. 2021;178:109407.

Behrens BA, Hübner S, Wölki K. Acoustic emissions during tensile test of DC06 and HCT600X. Mater Sci Eng Technol. 2019;50(7):796-809.

Pattnaik AB, Das S, Jha BB, Prasanth N. Effect of Al–5Ti–1B grain refiner on the microstructure, mechanical properties and acoustic emission characteristics of Al5052 aluminium alloy. J Mater Res Technol. 2015;4(2):171-9.

Vanniamparambil PA, Guclu U, Kontsos A. Identification of crack initiation in aluminum alloys using acoustic emission. Exp Mech. 2015;55:837-50.

Anay R, Soltangharaei V, Assi L, DeVol T, Ziehl P. Identification of damage mechanisms in cement paste based on acoustic emission. Constr Build Mater. 2018;164:286-96.

Gu Q, Ma Q, Tan Y, Jia Z, Zhao Z, Huang D. Acoustic emission characteristics and damage model of cement mortar under uniaxial compression. Constr Build Mater. 2019;213:377-85.

Japanese Industrial Standard. JIS Z 2201:1998 Test pieces for tensile test for metallic materials. Tokyo: JIS; 1998.

Ono K. Application of acoustic emission for structure diagnosis. Diagnostyka. 2011;2(58):3-18.

Hase A, Mishina H, Wada M. Correlation between features of acoustic emission signals and mechanical wear mechanisms. Wear. 2012;292-293:144-50.

Mlikota M, Schmauder S. On the critical resolved shear stress and its importance in the fatigue performance of steels and other metals with different crystallographic structures. Metals. 2018;8(11):883.

Guo Y, Paramatmuni C, Avcu E. Void nucleation and growth from heterophases and the exploitation of new toughening mechanisms in metals. Crystals. 2023;13(6):860.

Naznin H, Mallik AK, Hossain KS, Shahruzzaman MD, Haque P, Rahman MM. Enhancement of thermal and mechanical properties of PMMA composites by incorporating mesoporous micro-silica and GO. Results Mater. 2021;11:100203.