Optimal boosted framework for fatigue cracking prediction in polyethylene terephthalate pavement

Main Article Content

Abstract

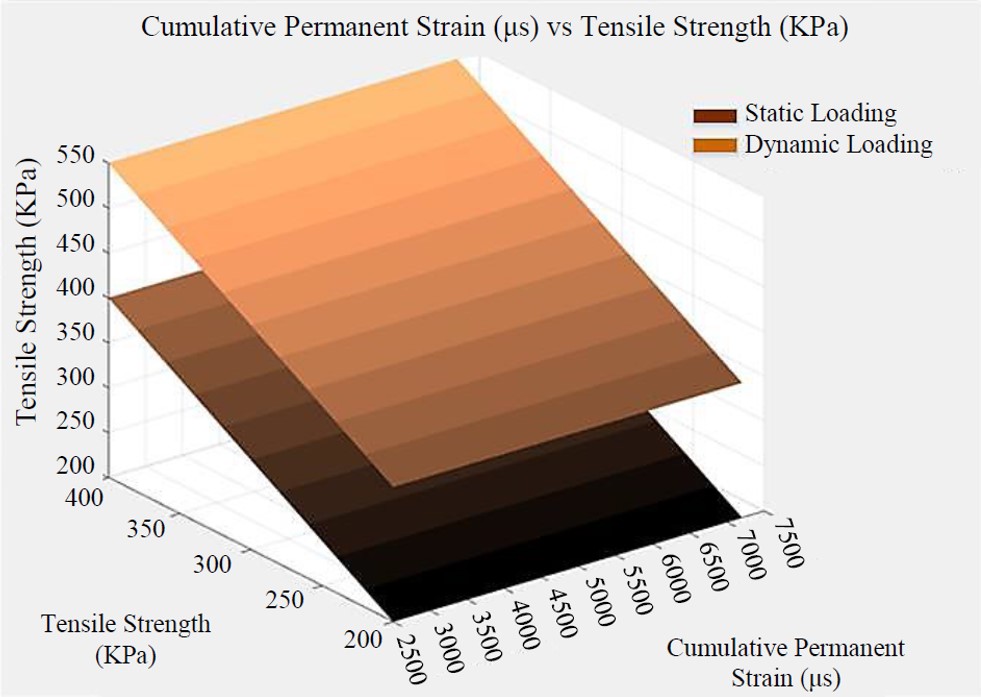

Depleting natural resources for construction purposes and research needs in the field of civil engineering is becoming a dependable process. To minimize this degradation process several techniques are implemented, one such method is using software approaches in research fields. In the consideration of the former investigation works, the focus point of the works is mainly on Crack Prediction on bitumen pavements. Since the bitumen pavement undergoes repeated loading under wheel loads in static conditions during traffic, and is dynamically loaded during the movement of fast moving vehicles. The strength parameters related to the fatigue limit of the bitumen are not analysed. Hence the fatigue limit of the bitumen should also be analysed. To analyze such conditions, deep learning with standardizing features is implemented to estimate the effective Strength parameters and to forecast the essential outcomes. In this study, the Fatigue Cracking Prediction of the Polymer Modified Bitumen (PMB) of grade 40 in Polyethylene Terephthalate (PET) Pavement is carried out. The Suggested Methodology is termed as Hyena based Curriculum Learning (HbCL). It is implemented in the Accuracy Prediction of Fatigue Cracking behaviour of PET pavement at different temperatures in dynamic and static load conditions. The fitness function in the optimization was triggered initially, to determine the ideal strength parameters of the Polymer Modified Bitumen as well as the PET. The tensile strength of the proposed model is 410 KPa in dynamic loading. The compression strength of the proposed model decreases with an increase in temperature. The rutting depth of the proposed model is between 1.7728mm and 1.6870mm. The Marshall Coefficient value gained was 2.7 KN/mm as the maximum for static loading. A value of 1.77mm in maximum is achieved by fatigue crack depth under dynamical load. The mean fatigue crack prediction accuracy estimated was 96.1%.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

Khedaywi T, Haddad M, Bataineh H. Effect of waste plastic polyethylene terephthalate on properties of asphalt cement. Innov Infrastruct Solut. 2023;8:232.

Al-Hadithi AI, Almawla SA, Mohammed MK. Fresh, mechanical and impact properties of self-compacting lightweight concrete containing waste PET fibers. Innov Infrastruct Solut. 2023;8:268.

Dereje B, Rath B, Gatkuoth K, Getachew K, Praveenkumar TR, Garoma S, et al. Thermal stress–strain analysis of CFRP-laminated concrete beam with partial replacement of fine aggregate by PET granules. Innov Infrastruct Solut. 2023;8:249.

Matarneh S, Elghaish F, Rahimian FP, Abdellatef E, Abrishami S. Evaluation and optimisation of pre-trained CNN models for asphalt pavement crack detection and classification. Autom Constr. 2024;160:105297.

Xiong Y, Wang H. Analysis of the grouting fullness and road performance of hot-recycled semi-flexible pavement materials. Case Stud Constr Mater. 2024;20:e02755.

Maljaars J, Leander J, Nussbaumer A, Sørensen JD, Straub D. Models and methods for probabilistic safety assessment of steel structures subject to fatigue. Struct Saf. 2024:102446.

Gu X, Xu X, Zhang Q, Sun L, Zhou Z. Study on the correlation between spatial variability of asphalt mixture material parameters and fracture performance. Case Stud Constr Mater. 2024;20:e02989.

Fletcher DI, Corteen J, Wilby A. Rough surface rolling contact fatigue crack stress intensity factor calculation for modern rail steels. Wear. 2024;540-541:205231.

Vinodhini KA, Sidhaarth KRA. Pothole detection in bituminous road using CNN with transfer learning. Meas: Sens. 2024;31:100940.

Al Ashaibi A, Wang Y, Albayati A, Weekes L, Haynes J. Uni-and tri-axial tests and property characterization for thermomechanical effect on hydrated lime modified asphalt concrete. Constr Build Mater. 2024;418:135307.

Chunping W, Jianfeng L, Liang C, Jian L, Lu W, Yilin L. Creep constitutive model considering nonlinear creep degradation of fractured rock. Int J Min Sci Technol. 2024;34(1):105-16.

Ren S, Liu X, Erkens S. Insight into the critical evaluation indicators for fatigue performance recovery of rejuvenated bitumen under different rejuvenation conditions. Int J Fatigue. 2023;175:107753.

Li X, Fu J, Yang F, Cao HL, Zhang Z, Liu F, et al. Laboratory investigation for the bridge deck pavement performance of conventional asphalt mixtures based on fuzzy comprehensive evaluation method. Case Stud Constr Mater. 2024;20:e02784.

Upadhya A, Thakur MS, Sihag P, Kumar R, Kumar S, Afeeza A, et al. Modelling and prediction of binder content using latest intelligent machine learning algorithms in carbon fiber reinforced asphalt concrete. Alex Eng J. 2023;65:131-49.

Zhu L, Li J, Xiao F. Carbon emission quantification and reduction in pavement use phase: a review. J Traffic Transp Eng. (Engl Ed). 2024;11(1):69-91.

Maha Madakalapuge C, Dutta TT, Kodikara J. Evaluation of climatic effects on moisture variation and performance of unbound pavements with sprayed seals. Acta Geotech. 2024;19:5481-502.

Bhandari S, Luo X, Wang F. Understanding the effects of structural factors and traffic loading on flexible pavement performance. Int J Transp Sci Technol. 2023;12(1):258-72.

Baradaran S, Rahimi J, Ameri M, Maleki A. Mechanical performance of asphalt mixture containing eco-friendly additive by recycling PET. Case Stud Constr Mater. 2024;20:e02740.

Genet MB, Sendekie ZB, Jembere AL. Investigation and optimization of waste LDPE plastic as a modifier of asphalt mix for highway asphalt: case of Ethiopian roads. Case Stud Chem Environ Eng. 2021;4:100150.

Yaro NSA, Sutanto MH, Habib NZ, Napiah M, Usman A, Al-Sabaeei AM, et al. Mixture design-based performance optimization via response surface methodology and moisture durability study for palm oil clinker fine modified bitumen asphalt mixtures. Int J Pavement Res Technol. 2024;17:123-50.

Li N, Zhan H, Yu X, Tang W, Yu H, Dong F. Research on the high temperature performance of asphalt pavement based on field cores with different rutting development levels. Mater Struct. 2021;54:70.

Jwaida Z, Dulaimi A, Bahrami A, Mydin MAO, Özkılıç YO, Jaya RP, et al. Analytical review on potential use of waste engine oil in asphalt and pavement engineering. Case Stud Constr Mater. 2024;20:e02930.

Benedetti M, du Plessis A, Ritchie RO, Dallago M, Razavi N, Berto F. Architected cellular materials: a review on their mechanical properties towards fatigue-tolerant design and fabrication. Mater Sci Eng R: Rep. 2021;144:100606.

Heidarian P, Mokhtari F, Naebe M, Henderson LC, Varley RJ. Reclamation and reformatting of waste carbon fibers: a paradigm shift towards sustainable waste management. Resour Conserv Recycl. 2024;203:107465.

Zhang X, Saba RG, Chen H, Hoff I, Liu J, Wang F. Research on asphalt surface layer performance over service time and establishment of ageing model for in-service bitumen under Norwegian conditions. Case Stud Constr Mater. 2024;20:e02824.

Aldagari S, Kabir SF, Fini EH. Investigating aging properties of bitumen modified with polyethylene-terephthalate waste plastic. Resour Conserv Recycl. 2021;173:105687.

Hossain MT, Shahid MA, Mahmud N, Habib A, Rana MM, Khan SA, et al. Research and application of polypropylene: a review. Discov Nano. 2024;19(1):1-21.

Chaturvedi AP, Suman SK. Rutting behavior estimation of polyethylene terephthalate bituminous layers under static and dynamic load at different temperature ranges. Innov Infrastruct Solut. 2024;9(1):18.

Ahmad MS, Ahmad SA. The impact of polyethylene terephthalate waste on different bituminous designs. J Eng Appl Sci. 2022;69(1):53.

Akbas MY, Karahancer S, Enieb M. Study on the effects of nano Sb2O3 on early and long-term aging behaviour of bitumen and asphalt mixtures. Ain Shams Eng J. 2021;12(4):3531-42.

Arifuzzaman M, Qureshi HJ, Al Fuhaid AF, Alanazi F, Javed MF, Eldin SM. Novel ensemble modelling for prediction of fundamental properties of bitumen incorporating plastic waste. J Mater Res Technol. 2023;24:3334-51.

Khusnutdinov I, Goncharova I, Safiulina A. Extractive deasphalting as a method of obtaining asphalt binders and low-viscosity deasphalted hydrocarbon feedstock from natural bitumen. Egypt J Pet. 2021;30(2):69-73.

Almusawi A, Shoman S, Lupanov AP. Assessment of the effectiveness and the initial cost efficiency of hot recycled asphalt using polymer modified bitumen. Case Stud Constr Mater. 2023;18:e02145.

Mirabdolazimi SM, Kargari AH, Pakenari MM. New achievement in moisture sensitivity of nano-silica modified asphalt mixture with a combined effect of bitumen type and traffic condition. Int J Pavement Res Technol. 2021;14:105-15.

Akbulut H, Gürer C. Investigation of the performance of silicone rubber modified bitumen. Silicon. 2022;14(15):9721-31.

Usanga IN, Ikeagwuani CC, Etim RK, Attah IC. Predictive modeling of modified asphalt mixture rutting potentials: machine learning approach. Iran J Sci Technol Trans Civ Eng. 2023;47(6):4087-101.

Rashed AM, Al-Hadidy AI. Comparative performance of DG mixes and SMA mixes with waste crumb rubber as aggregate replacement. Case Stud Constr Mater. 2023;19:e02615.

Zhou S, Song W. Crack segmentation through deep convolutional neural networks and heterogeneous image fusion. Autom Constr. 2021;125:103605.

Long XY, Zhao SK, Jiang C, Li WP, Liu CH. Deep learning-based planar crack damage evaluation using convolutional neural networks. Eng Fract Mech. 2021;246:107604.

Dais D, Bal İE, Smyrou E, Sarhosis V. Automatic crack classification and segmentation on masonry surfaces using convolutional neural networks and transfer learning. Autom Constr. 2021;125:103606.

Aldagari S, Kabir SF, Lamanna A, Fini EH. Functionalized waste plastic granules to enhance sustainability of bituminous composites. Resour Conserv Recycl. 2022;183:106353.