Mineralogical-based rock abrasivity assessment of siliciclastic and carbonate rocks observed in Mae Moh District, northern Thailand

Main Article Content

Abstract

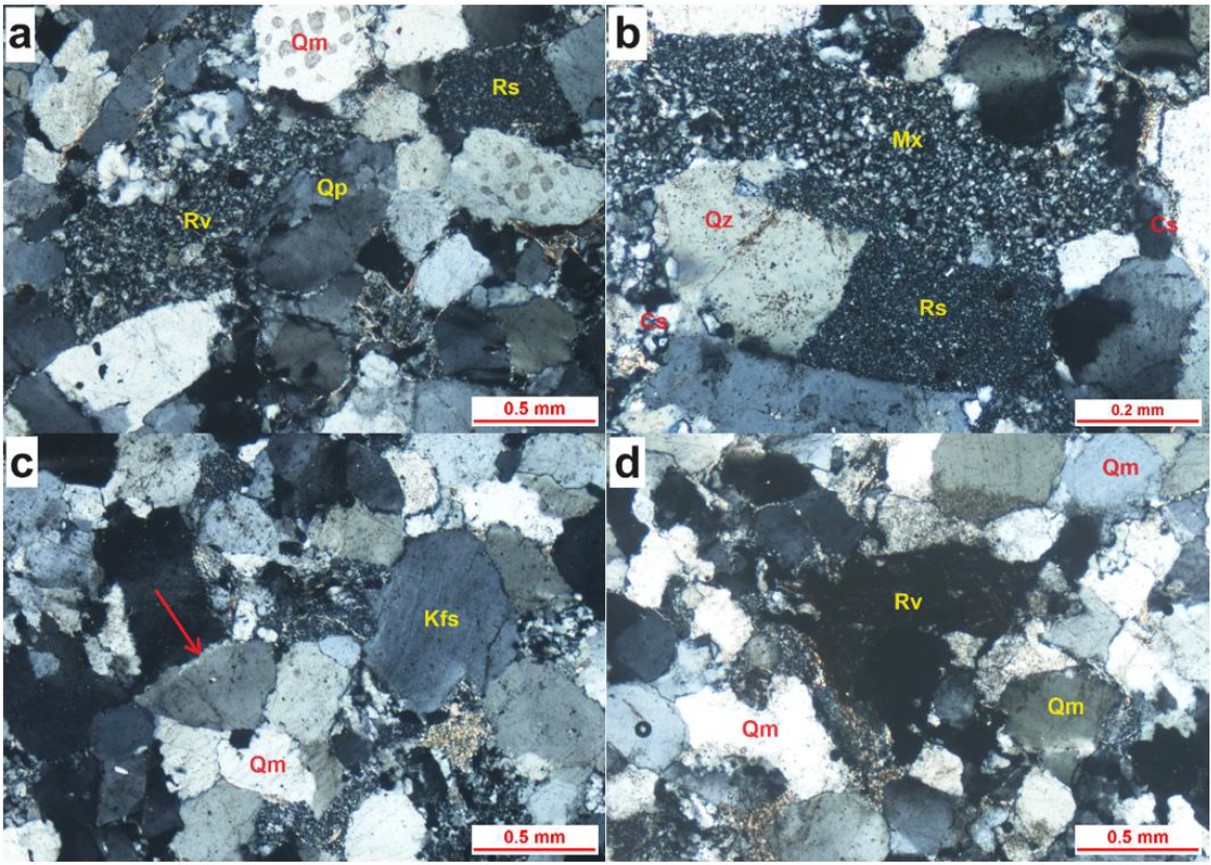

Understanding a target rock's characteristics and tool wear behaviors after cutting that rock significantly leads to appropriate tool selections and reliable tool lifetime prediction for ground excavation or drilling activities in mining and construction industries. Rock abrasivity is defined as the ability of rocks to cause damage to cutting tools. There are several methods for investigating the abrasivity of rocks ranging from micro-scale geotechnical approaches to real-scale in-situ tests. Applying mineralogical analysis to the rock abrasivity assessment methods for the tool wear prediction is lacking in detail, despite its simplicity, effectiveness, and affordability. This study preliminarily tests the abrasivity of four stratigraphic sedimentary units hosted in the Mae Moh Basin, northern Thailand, by investigating a rock abrasivity index (RAI). The method involves microscopic petrographic analysis, equivalent quartz content (EQC) determination, and the uniaxial compressive strength (UCS) tests. The RAI of each representative rock unit is a product of its EQC and UCS. The petrographic results reveal that the rock samples are sandstones and limestones. The sandstones can be divided into two subtypes including sublithic and lithic arenites with the EQC of 90.3% and 43.3%, respectively. The limestones, on the other hand, show the opposite values of below 3%. The UCS results suggest that the strengths of sandstones are higher than limestones. Additionally, the lithic-rich sandstone shows the highest UCS value (92.2 MPa). The calculated RAI of sandstones ranges from 39.9 to 72.5, indicating medium-to-very abrasive materials, whereas the limestones show RAI values of less than 2, indicating non-abrasive rocks. Determination of rock abrasivity using its mechanical and mineralogical properties appears to be a practical method for drilling or excavation strategies.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

Capik M, Yilmaz AO. Correlation between Cerchar abrasivity index, rock properties, and drill bit lifetime. Arab J Geosci. 2017;10:1-12.

Torrijo FJ, Garzón-Roca J, Company J, Cobos G. Estimation of Cerchar abrasivity index of andesitic rocks in Ecuador from chemical compounds and petrographical properties using regression analyses. Bull Eng Geol Environ. 2019;78(4):2331-44.

Abu Bakar MZ, Majeed Y, Rashid MA. Influence of propeller material hardness, testing time, rock properties, and conditioning on LCPC rock abrasiveness test. Bull Eng Geol Environ. 2021;80:1599-616.

Li Q, Li J, Duan L, Tan S. Prediction of rock abrasivity and hardness from mineral composition. Int J Rock Mech Min Sci. 2021;140:104658.

Plinninger RJ. Klassifizierung und Prognose von Werkzeugverschleiß bei konventionellenGebirgslösungsverfahren im Festgestein. Münchner Geologische Hefte, Reihe B: Angewandte Geologie. 2002;B17:1-146. (In German)

Plinninger RJ, Spaun G, Thuro K. Prediction and classification of tool wear in drill and blast tunnelling. In: van Rooy JL, Jermy CA, editors. Engineering Geology for Developing Countries - Proceedings of 9th Congress of the International Association for Engineering Geology and Environment; 2002 Sep 16-20; Durban, South Africa. p. 2226-36.

Plinninger RJ. Abrasiveness assessment for hard rock drilling. Geomech Tunnelbau. 2008;1(1):38-46.

Plinninger RJ, Restner U. Abrasiveness testing, Quo Vadis? - a commented overview of abrasiveness testing methods. Geomech Tunnelbau. 2008;1(1): 61-70.

Thuro K, Käsling H. Classification of the abrasiveness of soil and rock. Geomech Tunnelbau. 2009;2(2):179-88.

Plinninger RJ. Hardrock abrasivity investigation using the Rock Abrasivity Index (RAI). In: Williams AL, editor. Geologically Active. London: Taylor & Francis; 2010. p. 3445-2.

Kathancharoen N, Fuenkajorn K. Effects of mechanical and mineralogical properties on CERCHAR abrasivity index and specific energy of some Thai rocks. Eng Appl Sci Res. 2023;50(5):478-89.

Farhadian A, Ghasemi E, Hoseinie SH, Bagherpour R. Prediction of Rock Abrasivity Index (RAI) and Uniaxial Compressive Strength (UCS) of granite building stones using nondestructive tests. Geotech Geol Eng. 2022;40:3343-56.

Shi X, Tang Y, Chen S, Gao L, Wang Y. Experimental study on the sandstone abrasiveness via mineral composition and microstructure analysis. Petroleum. 2023;10(3):440-5.

Hassanpour J, Rostami J, Tarigh Azali S, Zhao J. Introduction of an empirical TBM cutter wear prediction model for pyroclastic and mafic igneous rocks: a case history of Karaj water conveyance tunnel, Iran. Tunn Undergr Space Technol. 2014;43:222-31.

Macias FJ, Dahl F, Bruland A. New rock abrasivity test method for tool life assessments on hard rock tunnel boring: The Rolling Indentation Abrasion Test (RIAT). Rock Mech Rock Eng. 2016;49(5):1679-93.

Kaspar M, Latal C. Der äquivalente Quarzgehalt – Historischer Rückblick und seine Zukunft in der Anwendung der Abrasivitätsprognose. Geotechnik. 2022;45(2):86-97. (In German)

Rosiwal A. Neuere Ergebnisse der Härtebestimmung von Mineralien und Gesteinen. - Ein absolutes Maß für die Härte spröder Körper. Verhandlungen der k. k. geologischen Reichsanstalt; 1916; Wien. p. 117-47. (In German)

Schimazek J, Knatz H. Die Beurteilung von Gesteinen durch Schneid- und Rollenbohrwerkzeuge. Erzmetall. 1976;29:113-19. (In German)

Thuro K. Drillability prediction: geological influences in hard rock drill and blast tunnelling. Geol Rundsch. 1997;86:426-38.

Verhoef PN. Wear of rock cutting tools: implications for the site investigation of rock dredging projects. Rotterdam: CRC Press; 1997.

Golodkovskaia GA, Krasilova NS, Ladygin VM, Shaumian LV. Factors controlling solid rock strength. Bull Int Assoc Eng Geol. 1975;11:65-9.

Bieniawski ZT, Bernede MJ. Suggested Methods for determining the uniaxial compressive strength and deformability of rock materials: part 1. Suggested method for determining deformability of rock materials in uniaxial compression. Int J Rock Mech Min Sci Geomech Abstr. 1979;16(2):138-40.

ASTM. ASTM D2938-95: Standard test method for unconfined compressive strength of intact rock core specimens. West Conshohocken: American Society for Testing and Materials; 2017.

ISRM. Suggested methods for determining point load strength. Int J Rock Mech Min Sci Geomech Abstr. 1985;22(2):51-60.

Beckhaus K, Thuro K. Abrasivität von Lockergestein in der Großbohrtechnik: Versuchstechnik und praktische Erfahrungen. 30 Baugrundtagung; 2008 Sep 24-27; Dortmund, Germany. Essen: Deutsche Gesellschaft für Geotechnik; 2008. p. 171-80. (In German)

Chaodumrong P. Stratigraphy, sedimentology and tectonic setting of the Lampang Group, central north Thailand [dissertation]. Tasmania: University of Tasmania; 1992.

Chaodumrong P, Burrett CF. Stratigraphy of the Lampang Group in central north Thailand: new version. CCOP Technical Bulletin. 1997;26:65-80.

Charusiri P, Ratanasthien B, Karnchanapayom P, Chaernthitirat T, Pailoplee S, Chitrmahantakul S, et al. Consulting, review, and evaluation geology Mae Moh Mine. Final report. Lampang, Thailand: Electricity Generating Authority of Thailand; 2020.

Pettijohn FJ. Sedimentary rocks. 2nd ed. New York: Harper and Row Publishers; 1975.

Folk RL. Practical petrographic classification of limestones. AAPG Bulletin. 1959;43:1-38.

Dunham RJ. Classification of carbonate rocks according to depositional texture. In: Ham WE, editor. Classification of Carbonate Rocks. Tulsa: AAPG; 1962. p. 108-21.

Attewell PB, Farmer IW. Principles of engineering geology. London: Chapman and Hall; 1976.

Ozturk CA, Nasuf E. Strength classification of rock material based on textural properties. Tunn Undergr Space Technol. 2013;34:45-54.

Dweirj M, Fraige F, Alnawafleh H, Titi A. Geotechnical characterization of Jordanian limestone. Geomaterials. 2017;7:1-12.

Huang S, He Y, Yu S, Cai C. Experimental investigation and prediction model for UCS loss of unsaturated sandstones under freeze-thaw action. Int J Min Sci Technol. 2022;32(1):41-9.

Ko TY, Kim TK, Son Y, Jeon S. Effect of geomechanical properties on Cerchar Abrasivity Index (CAI) and its application to TBM tunnelling. Tunn Undergr Space Technol. 2016;57:99-111.

Suana M, Peters T. The Cerchar Abrasivity Index and its relation to rock mineralogy and petrography. Rock Mechanics. 1982;15:1-8.

West G. Rock abrasiveness testing for tunnelling. Int J Rock Mech Min Sci Geomech Abstr. 1989;26(2):151-60.

Al-Ameen SI, Waller MD. The influence of rock strength and abrasive mineral content on the Cerchar Abrasive Index. Eng Geol. 1994;36(3-4):293-301.

Plinninger RJ, Käsling H, Thuro K, Spaun G. Testing conditions and geomechanical properties influencing the CERCHAR abrasiveness index (CAI) value. Int J Rock Mech Min Sci. 2003;40(2):259-63.

Zhang SR, She L, Wang C, Wang YJ, Cao RL, Li YL, et al. Investigation on the relationship among the Cerchar abrasivity index, drilling parameters and physical and mechanical properties of the rock. Tunn Undergr Space Technol. 2021;112:103907.