Effect of steel slag and ceramic residues on the physical and mechanical properties of concrete

Main Article Content

Abstract

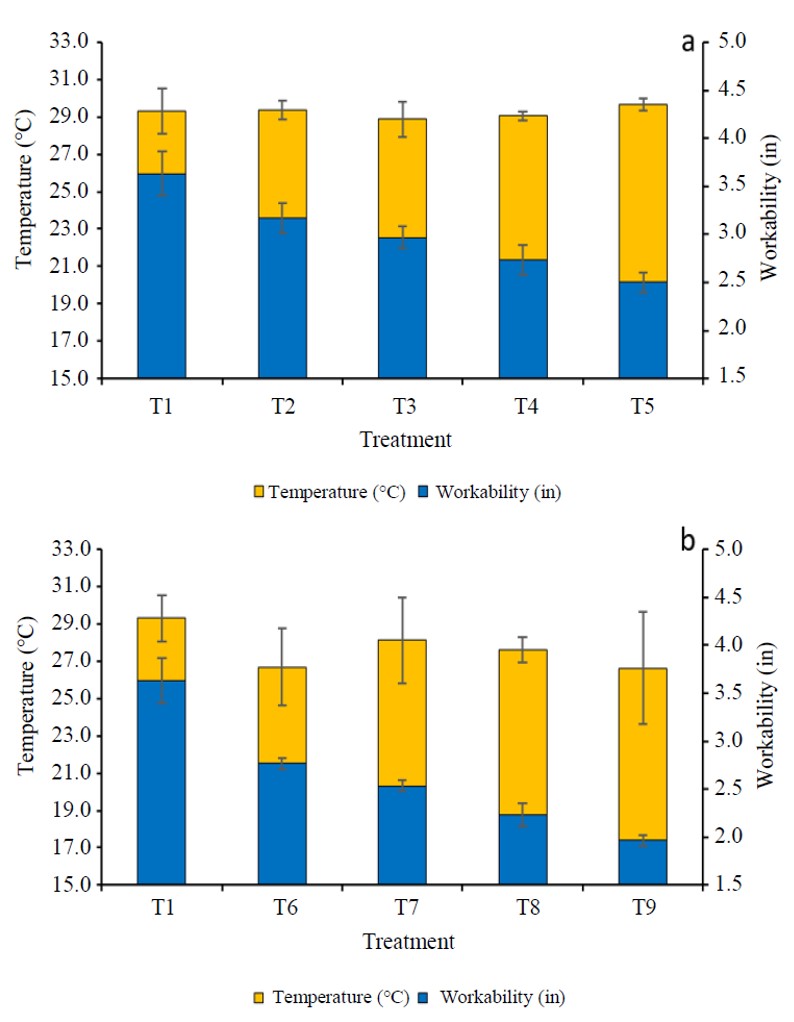

Cement is a critical component in concrete, but it significantly impacts the environment from extraction to disposal, depleting resources and generating pollution. To address this issue, the use of steel slag (SS) and ceramic waste powder (CWP) was investigated as partial replacements for cement at 8%, 10%, 12%, and 15% by weight. Various mixtures were evaluated, including a control mix with a water-to-cement (w/c) ratio of 0.52, mixtures containing SS, and an optimal blend of SS with different proportions of CWP. Physical and mechanical properties were assessed through slump tests, temperature measurements, air content, and density evaluations. Compressive strength, flexural strength, tensile strength, and modulus of elasticity were also analyzed at 7, 14, and 28 days using standardized cylindrical and prismatic specimens. The results indicated a reduction in slump and temperature of the concrete by up to 45.87% and 9.10%, respectively, with a slight increase in density and air content when incorporating 10% SS and 15% CWP. In terms of mechanical properties, the optimal substitution of 10% SS improved compressive strength by 7.39%, modulus of elasticity by 13.06%, flexural strength by 8.22%, and tensile strength by 14.10% compared to the control mix. The hybrid mix of SS and CWP (10%:10%) showed significant enhancements: compressive strength increased by 17.12%, flexural strength by 19.25%, tensile strength by 26.28%, and modulus of elasticity by 21.21%. It was concluded that substituting 10% SS and 10% CWP by weight of cement enhances the mechanical properties of concrete, promoting efficiency and sustainability in environmentally friendly construction. This hybrid concrete can be effectively used in pavements, sports floors, sidewalks, and curbs.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

Xiong Z, Mai G, Qiao S, He S, Zhang B, Wang H, et al. Fatigue bond behaviour between basalt fibre-reinforced polymer bars and seawater sea-sand concrete. Ocean Coast Manag. 2022;218:106038.

Xu D, Ni W, Wang Q, Xu C, Li K. Ammonia-soda residue and metallurgical slags from iron and steel industries as cementitious materials for clinker-free concretes. J Clean Prod. 2021;307:127262.

Zhu X, Li W, Du Z, Zhou S, Zhang Y, Li F. Recycling and utilization assessment of steel slag in metakaolin based geopolymer from steel slag by-product to green geopolymer. Constr Build Mater. 2021;305:124654.

Xiong Z, Lin L, Qiao S, Li L, Li Y, He S, et al. Axial performance of seawater sea-sand concrete columns reinforced with basalt fibre-reinforced polymer bars under concentric compressive load. J Build Eng. 2022;47:103828.

Rashad AM. Behavior of steel slag aggregate in mortar and concrete - a comprehensive overview. J Build Eng. 2022;53:104536.

Gencel O, Karadag O, Oren O, Bilir T. Steel slag and its applications in cement and concrete technology: a review. Constr Build Mater. 2021;283:122783.

Fisher LV, Barron AR. The recycling and reuse of steelmaking slags—a review. Resour Conserv Recycl. 2019;146:244-55.

Trento D, Ortega-Lopez V, Zanini MA, Faleschini F. Stress-strain behavior of electric arc furnace slag concrete under uniaxial compression: short- and long-term evaluation. Constr Build Mater. 2024;422:135837.

Beaucour AL, Pliya P, Faleschini F, Njinwoua R, Pellegrino C, Noumowé A. Influence of elevated temperature on properties of radiation shielding concrete with electric arc furnace slag as coarse aggregate. Constr Build Mater. 2020;256:119385.

Faleschini F, Zanini MA, Toska K. Seismic reliability assessment of code-conforming reinforced concrete buildings made with electric arc furnace slag aggregates. Eng Struct. 2019;195:324-39.

Santamaría A, Revilla-Cuesta V, Skaf M, Romera JM. Full-scale sustainable structural concrete containing high proportions of by-products and waste. Case Stud Constr Mater. 2023;18:e02142.

Pérez SPM, Viera JPF, Carranza JFG, Zapata LIV, Chumacero JMG, Brast CER, et al. Effect of crumb rubber and steel slag on asphalt mixtures for a micropavement. Innov Infrastruct Solut. 2024;9(2):37.

Revilla-Cuesta V, Serrano-López R, Espinosa AB, Ortega-López V, Skaf M. Analyzing the relationship between compressive strength and modulus of elasticity in concrete with ladle furnace slag. Buildings. 2023;13(12):3100.

López-Ausín V, Revilla-Cuesta V, Skaf M, Ortega-López V. Mechanical properties of sustainable concrete containing powdery ladle furnace slag from different sources. Powder Technol. 2024;434:119396.

Chang Q, Liu L, Farooqi MU, Thomas B, Özkılıç YO. Data-driven based estimation of waste-derived ceramic concrete from experimental results with its environmental assessment. J Mater Res Technol. 2023;24:6348-68.

Alarab A, Hamad B, Chehab G, Assaad JJ. Use of ceramic-waste powder as value-added pozzolanic material with improved thermal properties. J Mater Civ Eng. 2020;32(9):1-10.

Aksoylu C, Özkılıç Y, Bahrami A, Yıldızel S, Hakeem I, Özdöner N, et al. Application of waste ceramic powder as a cement replacement in reinforced concrete beams toward sustainable usage in construction. Retraction in: Case Stud Constr Mater. 2023;19:e02444.

Yang J, Jiang P, Nassar R, Suhail SA, Sufian M, Deifalla AF. Experimental investigation and AI prediction modelling of ceramic waste powder concrete–An approach towards sustainable construction. J Mater Res Technol. 2023;23:3676-96.

da Silva Rego JH, Sanjuán MA, Mora P, Zaragoza A, Visedo G. Carbon dioxide uptake by brazilian cement-based materials. Appl Sci. 2023;13(18):10386.

Chicoma A, Quiroz R, Muñoz S, Villena L. Influence of the physical and mechanical properties of concrete by adding rubber powder and silica fume. J Sustain Archit Civ Eng. 2023;32(1):205-23.

Muñoz Pérez SP, Pardo Becerra JM, García Chumacero JM, Diaz ES, Diaz Ortiz EA, Rodriguez Laffite ED, et al. Evaluation of the physical and mechanical properties of concrete with the incorporation of recycled concrete aggregate. Innov Infrastruct Solut. 2024;9(6):1-12.

Fernandez PJL, Huamán XAR, Marin MV. Analysis of recovery strategies for construction and demolition waste in the last 10 years: a review of the scientific literature. Proceedings of the 21st LACCEI International Multi-Conference for Engineering, Education and Technology; 2023 Jul 19-21; Buenos Aires, Argentina. p. 1-8.

Muñoz Perez SP, Salazar Pretel TM, Villena Zapata LI. Mechanical properties of a soil improved with recycled demolition concrete for the construction of shallow foundations. Mater Phys Mech. 2023;51(1):168-78.

Muñoz Perez SP, Garcia Chumacero JM, Charca Mamani S, Villena Zapata LI. Infuence of the secondary aluminum chip on the physical and mechanical properties of concrete. Innov Infrastruct Solut. 2023;8(1):45.

García Chumacero JM, Acevedo Torres PL, Corcuera La Portilla CC, Muñoz Perez SP. Influence of artificial intelligence on the optimization of the dosage of natural hydraulic lime, plastic and metallic fibers on the geological characteristics of a treated soil. Rev Ing Constr. 2023;38(3):473-84.

García Chumacero JM, Gonzales Macedo JL, Sánchez Castillo DJ. Contribution of agricultural ashes and HDPE as a waste material for a sustainable environment applied to the stabilization of a low plasticity clay soil. Innov Infrastruct Solut. 2024;9(3):67.

Bhargav M, Kansal R. Experimental investigation to substitute of cement with ceramic tiles powder in concrete. Int J Res Appl Sci Eng Technol. 2020;8(9):302-7.

Aguilar R, Blanco D. Diseño de concreto con sustitución parcial del cemento por escoria de acero en elementos estructurales horizontales de viviendas unifamiliares para reducir la huella de carbono ocasionada por la industria cementera en la ciudad de Lima [thesis]. Lima: Universidad Peruana de Ciencias Aplicadas; 2022. (In Spanish)

Altamirano A, Zapata R. Evaluación de las propiedades físico-mecánicas del concreto sustituyendo parcialmente el cemento por residuos cerámicos reforzado con cáscara de huevo [thesis]. Chiclayo: Universidad Señor de Sipán; 2023. (In Spanish)

Gallardo O, Pariona D. Adición de fibra de acero y desecho cerámico para mejorar la resistencia del concreto f’c = 245 kg/cm2, Lima, 2023 [thesis]. Lima: Universidad César Vallejo; 2023. (In Spanish)

Guerrero N. Influencia de los cerámicos reciclados en las propiedades físicas y mecánicas del concreto f'c 210 kg/cm2 en Jaén 2022 [thesis]. Tarapoto: Universidad César Vallejo; 2022. (In Spanish).

Sha F, Liu P, Ding Y. Application investigation of high-phosphorus steel slag in cementitious material and ordinary concrete. J Mater Res Technol. 2021;11:2074-91.

Hussain I, Ali B, Rashid MU, Amir MT, Riaz S, Ali A. Engineering properties of factory manufactured paving blocks utilizing steel slag as cement replacement. Case Stud Constr Mater. 2021;15:e00755.

Zhuo KX, Liu GT, Lan XW, Zheng DP, Wu SQ, Wu PZ, et al. Fracture behavior of steel slag powder-cement-based concrete with different steel-slag-powder replacement ratios. Materials. 2022;15(6):2243.

Pan Z, Zhou J, Jiang X, Xu Y, Jin R, Ma J, et al. Investigating the effects of steel slag powder on the properties of self-compacting concrete with recycled aggregates. Constr Build Mater. 2019;200:570-7.

El-Dieb AS, Kannan DM. Ceramic waste powder an alternative cement replacement – characterization and evaluation. Sustain Mater Technol. 2018;17:e00063.

Li L, Joseph P, Zhang X, Zhang L. A study of some relevant properties of concrete incorporating waste ceramic powder as a cement replacement agent. J Build Eng. 2024;87:109106.

Taher MJ, Abed EH, Hashim MS. Using ceramic waste tile powder as a sustainable and eco-friendly partial cement replacement in concrete production. Mater Today Proc. Inpress 2023.

Gu X, Li Z, Zhang Y, Zhang W, Li X, Liu B. Sustainable assessment and synergism of ceramic powder and steel slag in iron ore tailings-based concrete. Environ Sci Pollut Res. 2024;31:18856-70.

Palod R, Deo SV, Ramtekkar GD. Sustainable approach for Linz-Donawitz slag waste as a replacement of cement in concrete: mechanical, microstructural, and durability properties. Adv Civ Eng. 2020;2020(1):1-9.

ASTM. ASTM C136: Standard test method for sieve analysis of fine and coarse aggregates. West Conshohocken: ASTM International; 2015.

ASTM. ASTM C1602/C1602M: Standard specification for mixing water used in the production of hydraulic cement concrete. West Conshohocken: ASTM International; 2022.

ASTM. ASTM C29/C29M: Standard test method for bulk density (“unit weight”) and voids in aggregate. West Conshohocken: ASTM International; 2023.

ASTM. ASTM C128: Standard test method for relative density (specific gravity) and absorption of fine aggregate. West Conshohocken: ASTM International; 2023.

ASTM. ASTM C127: Standard test method for relative density (specific gravity) and absorption of coarse aggregate (withdrawn 2024). West Conshohocken: ASTM International; 2024.

ASTM. ASTM C566: Standard test method for total evaporable moisture content of aggregate by drying. West Conshohocken: ASTM International; 2019.

ASTM. ASTM C143/C143M: Standard test method for slump of hydraulic-cement concrete. West Conshohocken: ASTM International; 2020.

ASTM. ASTM C138/C138M: Standard test method for density (unit weight), yield, and air content (gravimetric) of concrete. West Conshohocken: ASTM International; 2023.

ASTM. ASTM C1064/C1064M: Standard test method for temperature of freshly mixed hydraulic-cement concrete. West Conshohocken: ASTM International; 2023.

ASTM. ASTM C173/C173M: Standard test method for air content of freshly mixed concrete by the volumetric method. West Conshohocken: ASTM International; 2023.