An integration of multi-objective goal programming and linear assignment models based on grey relational analysis for the collaborative robot assignment problem in Human-Robot Collaboration (HRC): An application of industry 5.0

Main Article Content

Abstract

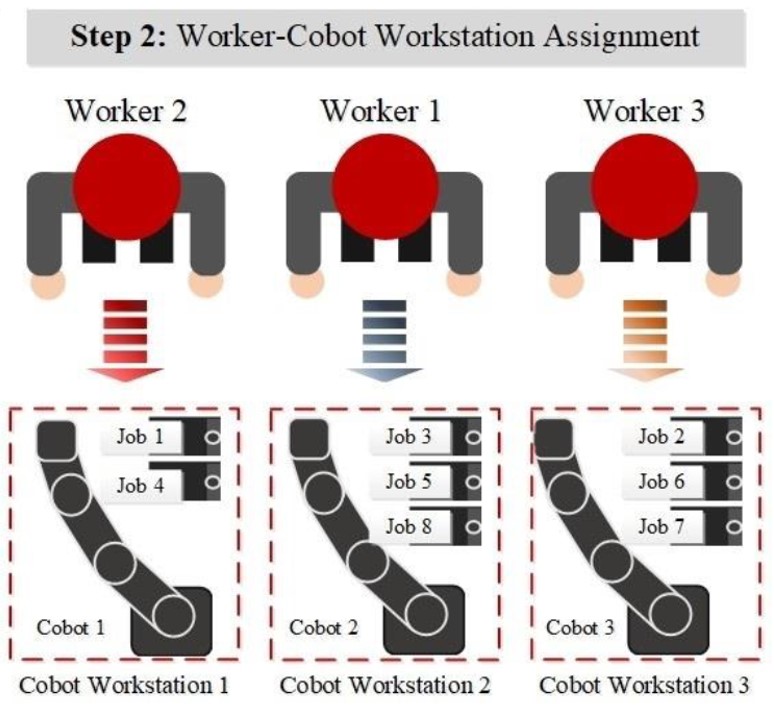

This research presents a novel two-step assignment method for forming cobot workstations to facilitate collaboration between humans and cobots, in alignment with the Industry 5.0 concept. The method is based on Grey Relational Analysis (GRA) to address limitations in existing cobot task allocation approaches, which typically focus on single-objective optimization. The first step involves a lexicographic goal programming model with dual objectives, optimizing cobot-job and job-cobot assignments. These objectives aim to maximize the mean of the total grey relational grade for both assignments, resulting in optimal cobot-job pairings. In the second step, the integrated GRA assignment model determines the appropriate worker for each cobot set. An illustrative example and comparative analysis demonstrate the advantages of the proposed method over traditional approaches.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

Tan Q, Tong Y, Wu S, Li D. Anthropocentric approach for smart assembly: integration and collaboration. J Robot. 2019;2019(1):3146782.

Michalos G, Spiliotopoulos J, Makris S, Chryssolouris G. A method for planning human robot shared tasks. CIRP J Manuf Sci Technol. 2018;22:76-90.

Inkulu AK, Raju Bahubalendruni MVA, Dara A, SankaranarayanaSamy K. Challenges and opportunities in human robot collaboration context of Industry 4.0 - a state of the art review. Ind Robot. 2022;49(2):226-39.

Colgate JE, Wannasuphoprasit W, Peshkin MA. Cobots: robots for collaboration with human operators. ASME International Mechanical Engineering Congress and Exposition; 1996 Nov 17-22; Atlanta, USA. USA: ASME; 1996. p. 433-9.

Nahavandi S. Industry 5.0—a human-centric solution. Sustainability. 2019;11(16):4371.

Liao S, Lin L, Chen Q. Research on the acceptance of collaborative robots for the industry 5.0 era -- The mediating effect of perceived competence and the moderating effect of robot use self-efficacy. Int J Ind Ergon. 2023;95:103455.

Pizon J, Cioch M, Kański Ł, Sánchez García E. Cobots implementation in the era of industry 5.0 using modern business and management solutions. Adv Sci Technol Res J. 2022;16(6):166-78.

Prassida GF, Asfari U. A conceptual model for the acceptance of collaborative robots in industry 5.0. Procedia Comput Sci. 2022;197:61-7.

Statista. Martin Placek. 2023 [cited 2024 Dec 12]. Available from: https://www.statista.com/forecasts/1461473/ai-robot-market-size-europe.

El Zaatari S, Marei M, Li W, Usman Z. Cobot programming for collaborative industrial tasks: an overview. Robot Auton Syst. 2019;116:162-80.

Simões AC, Pinto A, Santos J, Pinheiro S, Romero D. Designing human-robot collaboration (HRC) workspaces in industrial settings: a systematic literature review. J Manuf Syst. 2022;62:28-43.

Baratta A, Cimino A, Gnoni MG, Longo F. Human robot collaboration in industry 4.0: a literature review. Procedia Comput Sci. 2023;217:1887-95.

Liau YY, Ryu K. Task allocation in Human-Robot Collaboration (HRC) based on task characteristics and agent capability for mold assembly. Procedia Manuf. 2020;51:179-86.

Carter M, Price CC, Rabadi G. Operations research: a practical introduction. 2nd ed. Boca Raton: CRC Press; 2018.

Skovira J, Chan W, Zhou H, Lifka D. The EASY — LoadLeveler API project. In: Feitelson DG, Rudolph L, editors. Job Scheduling Strategies for Parallel Processing. JSSPP 1996. Lecture Notes in Computer Science, vol 1162. Berlin: Springer; 1996.

Liau YY, Ryu K. Genetic algorithm-based task allocation in multiple modes of human robot collaboration systems with two cobots. Int J Adv Manuf Technol. 2022;119(11):7291-309.

Bänziger T, Kunz A, Wegener K. Optimizing human robot task allocation using a simulation tool based on standardized work descriptions. J Intell Manuf. 2020;31(7):1635-48.

Raatz A, Blankemeyer S, Recker T, Pischke D, Nyhuis P. Task scheduling method for HRC workplaces based on capabilities and execution time assumptions for robots. CIRP Annals. 2020;69(1):13-6.

Dalle Mura M, Dini G. Designing assembly lines with humans and collaborative robots: a genetic approach. CIRP Annals. 2019;68(1):1-4.

Dalle Mura M, Dini G. Optimizing ergonomics in assembly lines: a multi objective genetic algorithm. CIRP J Manuf Sci Technol. 2019;27:31-45.

Gombolay MC, Wilcox RJ, Shah JA. Fast scheduling of robot teams performing tasks with temporospatial constraints. IEEE Trans Robot. 2018;34(1):220-39.

Mao Z, Zhang J, Fang K, Huang D, Sun Y. Balancing U-type assembly lines with human-robot collaboration. Comput Oper Res. 2023;159:106359.

Mokhtarzadeh M, Tavakkoli-Moghaddam R, Vahedi-Nouri B, Farsi A. Scheduling of human-robot collaboration in assembly of printed circuit boards: a constraint programming approach. Int J Comput Integr Manuf. 2020;33(5):460-73.

Stecke KE, Mokhtarzadeh M. Balancing collaborative human-robot assembly lines to optimise cycle time and ergonomic risk. Int J Prod Res. 2022;60(1):25-47.

Guo D. Fast scheduling of human-robot teams collaboration on synchronized production-logistics tasks in aircraft assembly. Robot Comput-Integr Manuf. 2024;85:102620.

Takata S, Hirano T. Human and robot allocation method for hybrid assembly systems. CIRP Annals. 2011;60(1):9-12.

Chen F, Sekiyama K, Cannella F, Fukuda T. Optimal subtask allocation for human and robot collaboration within hybrid assembly system. IEEE Trans Autom Sci Eng. 2014;11(4):1065-75.

Malvankar-Mehta MS, Mehta SS. Optimal task allocation in multi-human multi-robot interaction. Optim Lett. 2015;9(8):1787-803.

Tsarouchi P, Makris S, Chryssolouris G. Human robot interaction review and challenges on task planning and programming. Int J Comput Integr Manuf. 2016;29(8):916-31.

Faber M, Mertens A, Schlick CM. Cognition-enhanced assembly sequence planning for ergonomic and productive human-robot collaboration in self-optimizing assembly cells. Prod Eng. 2017;11:145-54.

Ranz F, Hummel V, Sihn W. Capability-based task allocation in human-robot collaboration. Procedia Manuf. 2017;9:182-9.

Tsarouchi P, Matthaiakis AS, Makris S, Chryssolouris G. On a human-robot collaboration in an assembly cell. Int J Comput Integr Manuf. 2017;30(6):580-9.

Blankemeyer S, Recker T, Stuke T, Brokmann J, Geese M, Reiniger M, et al. A method to distinguish potential workplaces for human-robot collaboration. Procedia CIRP. 2018;76:171-6.

Bilberg A, Malik AA. Digital twin driven human robot collaborative assembly. CIRP Annals. 2019;68(1):499-502.

Ijtsma M, Ma LM, Pritchett AR, Feigh KM. Computational methodology for the allocation of work and interaction in human-robot teams. J Cogn Eng Decis Mak. 2019;13(4):221-41.

Malik AA, Bilberg A. Complexity-based task allocation in human-robot collaborative assembly. Ind Robot. 2019;46(4):1-10.

Bettoni A, Montini E, Righi M, Villani V, Tsvetanov R, Borgia S, et al. Mutualistic and adaptive human-machine collaboration based on machine learning in an injection moulding manufacturing line. Procedia CIRP. 2020;93:395-400.

Evangelou G, Dimitropoulos N, Michalos G, Makris S. An approach for task and action planning in human robot collaborative cells using AI. Procedia CIRP. 2021;97:476-81.

Kinast A, Doerner KF, Rinderle-Ma S. Combining metaheuristics and process mining: Improving cobot placement in a combined cobot assignment and job shop scheduling problem. Procedia Comput Sci. 2022;200:1836-45.

Lee ML, Behdad S, Liang X, Zheng M. Task allocation and planning for product disassembly with human robot collaboration. Robot Comput-Integr Manuf. 2022;76:102306.

Messeri C, Bicchi A, Zanchettin AM, Rocco P. A dynamic task allocation strategy to mitigate the human physical fatigue in collaborative robotics. IEEE Robot Autom Lett. 2022;7(2):2178-85.

Pabolu VKR, Shrivastava D, Kulkarni MS. A digital-twin based worker's work allocation framework for a collaborative assembly system. IFAC-PapersOnLine. 2022;55(10):1887-92.

Sun X, Zhang R, Liu S, Lv Q, Jinsong B, Li J. A digital twin-driven human-robot collaborative assembly-commissioning method for complex products. Int J Adv Manuf Technol. 2022;118:3389-402.

Zhang R, Lv Q, Li J, Bao J, Liu T, Liu S. A reinforcement learning method for human-robot collaboration in assembly tasks. Robot Comput-Integr Manuf. 2022;73:102227.

Dauzère-Pérès S, Ding J, Shen L, Tamssaouet K. The flexible job shop scheduling problem: a review. Eur J Oper Res.. 2024;314(2):409-32.

Faccio M, Granata I, Minto R. Task allocation model for human-robot collaboration with variable cobot speed. J Intell Manuf. 2024;35:793-806.

Wang S, Zhang J, Wang P, Law J, Calinescu R, Mihaylova L. A deep learning-enhanced Digital Twin framework for improving safety and reliability in human-robot collaborative manufacturing. Robot Comput-Integr Manuf. 2024;85:102608.

Unhelkar VV, Yang JX, Shah JA. Challenges for communication decision-making in sequential human-robot collaborative tasks. Workshop on Mathematical Models, Algorithms, and Human-Robot Interaction (RSS2017); 2017 Jul 12-16; Boston, USA. p. 1-4.

Unhelkar V, Li S, Shah JA. Decision-making for bidirectional communication in sequential human-robot collaborative tasks. The15th ACM/IEEE International Conference on Human-Robot Interaction (HRI); 2020 Mar 23-26; Cambridge, United Kingdom. p. 329-41.

Robotiq. The top 5 cobot kpis: how to measure and improve the performance of collaborative robots. 2018 [cited 2024 Dec 12]. Available from: https://blog.robotiq.com/top-five-kpis-for-cobots.

Shen Y, Reinhart G. Safe assembly motion - a novel approach for applying human-robot cooperation in hybrid assembly systems. 2013 IEEE International Conference on Mechatronics and Automation; 2013 Aug 4-7; Takamastu, Japan. p. 7-12.

Gombolay MC, Gutierrez RA, Clarke SG, Sturla GF, Shah JA. Decision-making authority, team efficiency and human worker satisfaction in mixed human robot teams. Auton Robot. 2015;39(3):293-312.

Gualtieri L, Rauch E, Vidoni R, Matt DT. Safety, ergonomics and efficiency in human-robot collaborative assembly: design guidelines and requirements. Procedia CIRP. 2020;91:367-72.

Zanella A, Cisi A, Costantino M, Di Pardo M, Pasquettaz G, Vivo G. Criteria definition for the identification of HRC use cases in automotive manufacturing. Procedia Manuf. 2017;11:372-9.

Drexl A, Kimms A. Optimization guided lower and upper bounds for the resource investment problem. J Oper Res Soc. 2001;52(3):340-51.

Chen H, Li J, Wan W, Huang Z, Harada K. Integrating combined task and motion planning with compliant control. Int J Intell Robot Appl. 2020;4(2):149-63.

Ritt M, Costa AM, Miralles C. The assembly line worker assignment and balancing problem with stochastic worker availability. Int J Prod Res. 2016;54(3):907-22.

Oliff H, Liu Y, Kumar M, Williams M. Integrating intelligence and knowledge of human factors to facilitate collaboration in manufacturing. ASME 2018 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference; 2018 Aug 26-29; Quebec, Canada. p. 1-10.

Niakan F, Baboli A, Moyaux T, Botta-Genoulaz V. A bi-objective model in sustainable dynamic cell formation problem with skill-based worker assignment. J Manuf Syst. 2016;38:46-62.

Norman BA, Tharmmaphornphilas W, Needy KL, Bidanda B, Warner RC. Worker assignment in cellular manufacturing considering technical and human skills. Int J Prod Res. 2002;40(6):1479-92.

Ju Long D. Control problems of grey systems. Syst Control Lett. 1982;1(5):288-94.

Xiao XC, Wang XQ, Fu KY, Zhao YJ. Grey relational analysis on factors of the quality of web service. Physics Procedia. 2012;33:1992-8.

Nayakappa PA, Walke Gaurish A, Mahesh G. Grey relation analysis methodology and its application. Int J Multidiscip. 2019;4(2):409-11.

Cenglin Y. Application of gray relational analysis method in comprehensive evaluation on the customer satisfaction of automobile 4s enterprises. Physics Procedia. 2012;33:1184-9.

Kung CY, Wen KL. Applying grey relational analysis and grey decision-making to evaluate the relationship between company attributes and its financial performance—a case study of venture capital enterprises in Taiwan. Decis Support Syst. 2007;43(3):842-52.

Zhang X. Venture capital investment base on grey relational theory. Physics Procedia. 2012;33:1825-32.

Hashemi SH, Karimi A, Tavana M. An integrated green supplier selection approach with analytic network process and improved Grey relational analysis. Int J Prod Econ. 2015;159:178-91.

Memon MS, Lee YH, Mari SI. Group multi-criteria supplier selection using combined grey systems theory and uncertainty theory. Expert Syst Appl. 2015;42(21):7951-9.

Haeri SAS, Rezaei J. A grey-based green supplier selection model for uncertain environments. J Clean Prod. 2019;221:768-84.

Rajesh R, Ravi V. Supplier selection in resilient supply chains: a grey relational analysis approach. J Clean Prod. 2015;86:343-59.

Lin ST, Horng SJ, Lee BH, Fan P, Pan Y, Lai JL, et al. Application of grey-relational analysis to find the most suitable watermarking scheme. Int J Innov Comput Inf Control. 2011;7(9):5389-401.

Nunkaew W, Kimaporn M. Lexicographic goal programming model for solving multi-objective worker assignment problems with grey relational analysis. The 7th Annual Conference on Engineering and Information Technology (ACEAIT2023); 2023 Jul 12-14; Osaka, Japan. p. 205-18.

Kimaporn M, Nunkaew W. A fuzzy inference system-based hybrid assignment method for cobot assignment problem. The 3rd International Conference on Robotics, Automation and Artificial Intelligence (RAAI); 2023 Dec 14-16; Singapore. USA: IEEE; 2023. p. 292-6.

Nunkaew W, Phruksaphanrat B. A multiobjective programming for transportation problem with the consideration of both depot to customer and customer to customer relationships. Proceedings of the International MultiConference of Engineers and Computer Scientists 2009; 2009 Mar 18-20; Hong Kong. p. 1-6.

Nunkaew W, Phruksaphanrat B. Lexicographic fuzzy multi-objective model for minimisation of exceptional and void elements in manufacturing cell formation. Int J Prod Res. 2014;52(5):1419-42.

Kimaporn M, Nunkaew W. Solving clustering and allocation problems of human-robot collaboration in smart industry 5.0 applications using FIS-GRA integration-based multi-objective programming model. International Conference on Informatics, Environment, Energy and Applications (IEEA 2024); 2024 Feb 21-23; Tokyo, Japan. p. 29-39.