Briquettes fuel production from sugarcane bagasse for sustainable community energy solutions

Main Article Content

Abstract

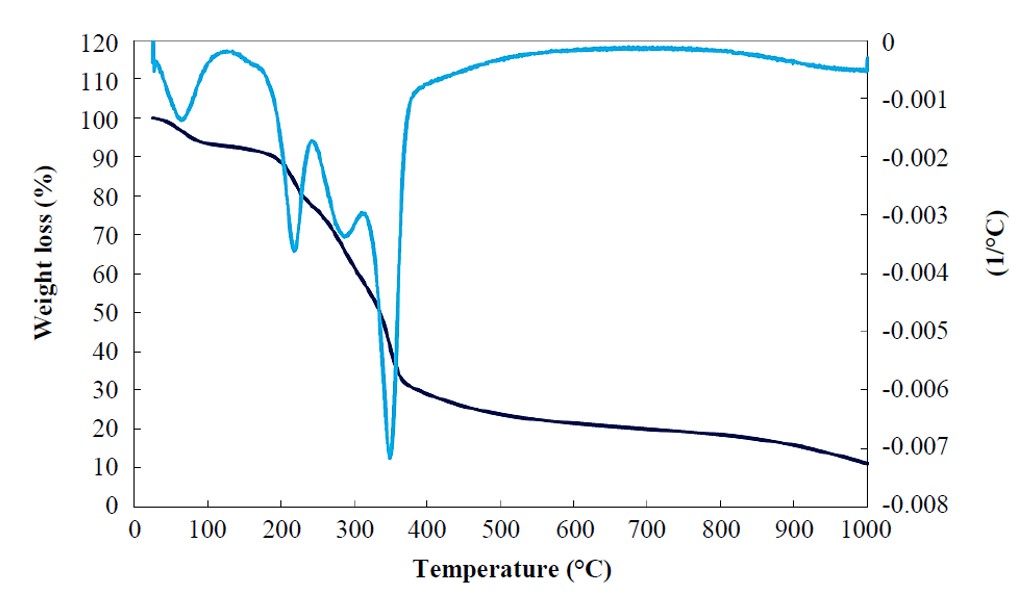

The objective of this study is to determine optimum conditions for producing briquettes fuel from biomass, examine the properties of the resulting briquette fuel and transfer the technology to target communities. The production process entails implementing a screw-type briquette press equipped with controlled temperatures through a molded pipe clamp electric heater for shaping the briquettes. This is an innovative approach that allows briquettes to be produced and ready for use in a single step, while other processes require the briquettes to be dried first. The production capacity was estimated to be 12 kg/hr. Bagasse, a byproduct of sugarcane processing, was the biomass used in the current research. For this study, four distinct temperatures were chosen for experimentation, 100, 110, 120, and 130°C. The proportions of bagasse, cassava flour, and water were investigated for briquette production utilizing two formulae: 1 kg bagasse to 0.1 kg cassava flour and 0.5 liters water, and 1 kg bagasse to 0.3 kg cassava flour and 0.5 liters water. The findings indicated that bagasse briquettes could be effectively manufactured at 120°C. The ideal proportion of bagasse particles, cassava starch, and water was 1 kg : 0.3 kg : 0.5 liters, respectively. The moisture content, volatile matter, ash, and fixed carbon were respectively 8.04, 70.20, 13.05, and 16.11 wt.% on a dry basis, based on the physical and chemical property tests of the briquette fuel. The material has a density of approximately 856.70 kg/m3, a compressive strength of 89.34 kg/cm2, and a higher heat value (HHV) of 24.05 MJ/kg, with a longer burning time than regular charcoal. The research emphasizes using bagasse for innovative renewable energy production technologies and disseminating this technology in target communities in Thailand.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

Bieniek A, Sieradzka M, Jerzak W, Magdziarz, A. Fast pyrolysis of agricultural biomass in drop tube reactor for bio-oil production: Numerical calculations. J Anal Appl Pyrolysis. 2023;176:106241.

Dimitriadis A, Bergvall N, Johansson AC, Sandstrom L, Bezergianni S, Tourlakidis N, et al. Biomass conversion via ablative fast pyrolysis and hydroprocessing towards refinery integration: Industrially relevant scale validation. Fuel. 2023;332:126153.

Ibitoye SE, Mahamood RM, Jen TC, Loha C, Akinlabi ET. An overview of biomass solid fuels: Biomass sources, processing methods, and morphological and microstructural properties. J Bioresour Bioprod. 2023;8(4):333-60.

Feng Y, Huang J, Zhang J, Yellezuome D, Zhao R, Chen T, et al. Mechanical pretreatment of typical agricultural biomass on shape characterization and NO emissions during combustion. Bioresour Technol. 2024;397:130477.

Liu J, Wu L, Wang R, Xue X, Wang D, Liang J. Evaluation of biomass sources on the production of biofuels from lignocellulosic waste over zeolite catalysts. Bioresour Technol. 2024;398:130510.

Lundmark R, Wetterlund E, Olofsson E. On the green transformation of the iron and steel industry: market and competition aspects of hydrogen and biomass options. Biomass Bioenergy. 2024;182:107100.

Shi Y, Jin Y, Svanberg R, Han T, Minidis ABE, Ann-Sof KD, et al. Continuous catalytic pyrolysis of biomass using a fluidized bed with commercial-ready catalysts for scale-up. Energy. 2023;273:127288.

Li R, Song G, Huang D, Hu S, Fantozzi F, Hassan A, et al. Comparative study of process simulation, energy and exergy analyses of solar enhanced char-cycling biomass pyrolysis process. Energy Convers Manag. 2024;302:118082.

Matamba T, Tahmasebi A, Yu J, Keshavarz A, Abid HR, Iglauer S. A review on biomass as a substitute energy source: Polygeneration influence and hydrogen rich gas formation via pyrolysis. J Anal Appl Pyrolysis. 2023;175:106221.

Akubo K, Nahil MA, Williams PT. Pyrolysis-catalytic steam reforming of agricultural biomass wastes and biomass components for production of hydrogen/syngas. J Energy Inst. 2019;92(6):1987-96.

Feng D, Shang Q, Song Y, Wang Y, Cheng Z, Zhao Y, et al. In-situ catalytic synergistic interaction between self-contained K and added Ni in biomass fast/slow pyrolysis. Renew Energy. 2024;222:119889.

Collard FX, Bensakhria A, Drobek M, Volle G, Blin J. Influence of impregnated iron and nickel on the pyrolysis of cellulose. Biomass Bioenergy. 2015;80:52-62.

Wiyono A, Aziz M, Sholehudin A, Sukrawan Y, Purnawan, Anggrainy R, et al. Syngas optimization and tar reduction via multistage catalytic gasification: Effects of catalyst pore, catalyzer stage, and temperature profile. S Afr J Chem Eng. 2024;48:246-53.

Makwana J, Dhass AD, Ramana PV, Sapariya D, Patel D. An analysis of waste/biomass gasification producing hydrogen-rich syngas: a review. Int J Thermofluids. 2023;20:100492.

Raj R, Singh DK, Tirkey JV. Co-gasification of Low-grade coal with Madhuca longifolia (Mahua) biomass and dual-fuelled mode engine performance: effect of biomass blend and engine operating condition. Energy Convers Manag. 2022;269:116150.

Ajikashile JO, Alhnidi MJ, Parku GK, Funke A, Kruse A. A study on the fast pyrolysis of millet and sorghum straws sourced from arid and semi-arid regions of Nigeria in a twin-screw mixing reactor. Mater Sci Energy Technol. 2023;6:388-98.

AlMallahi MN, Asaad SM, Rocha-Meneses L, Inayat A, Said Z, El Haj Assad M, et al. A case study on bio-oil extraction from spent coffee grounds using fast pyrolysis in a fluidized bed reactor. Case Stud Chem Environ Eng. 2023;8:100529.

Makepa DC, Chihobo CH, Ruziwa WR, Musademba D. A systematic review of the techno-economic assessment and biomass supply chain uncertainties of biofuels production from fast pyrolysis of lignocellulosic biomass. Fuel Communications. 2023;14:100086.

Moura P, Henriques J, Alexandre J, Oliveira AC, Abreu M, Gírio F, et al. Sustainable value methodology to compare the performance of conversion technologies for the production of electricity and heat, energy vectors and biofuels from waste biomass. Cleaner Waste Syst. 2022;3:100029.

Awasthi MK, Sarsaiya S, Wainaina S, Rajendran K, Awasthi SK, Liu T, et al. Technoeconomics and life-cycle assessment of biological and thermochemical treatment of bio-waste. Renew Sustain Energy Rev. 2021;144:110837.

Ortigueira J, Pacheco M, Trancoso MA, Farrancha P, Correia J, Silva C, et al. Food waste biorefnery: stability of an acidogenic fermentation system with carbon dioxide sequestration and electricity generation. J Clean Prod. 2020;270:122040.

FAO. World Food and Agriculture - Statistical Yearbook 2023. Rome: FAO; 2023.

Pattiya A. Thermochemical characterization of agricultural wastes from Thai cassava plantations. Energy Sources A: Recovery Util Environ Eff. 2011;33(8):691-701.

Abdu Karifa M, Habtu NG, Jembere AL, Genet MB. Characterization and evaluation of torrefed sugarcane bagasse to improve the fuel properties. Curr Res Green Sustain Chem. 2024;8:100395.

Marx S, Laubscher ANE, Bunt JR, Venter RJ, Uwaoma RC, Steydom CA. Evaluation of sugar cane bagasse hydrothermal liquefaction products for co-gasifcation with coal as green coal pellet production. Bioresour Technol Rep. 2023;22:101503.

Chen X, Liang J, Liao P, Huang W, He J, Chen J. Effect of process parameters and raw material characteristics on the physical and mechanical quality of sugarcane bagasse pellets. Biomass Bioenergy. 2021;154:106242.

Suttibak S, Loengbudnark W. Production of charcoal briquettes from biomass for community use. IOP Conf Ser: Mater Sci Eng. 2018;297:012001.

Karunanithy C, Wang Y, Muthukumarappan K, Pugalendhi S. Physiochemical characterization of briquettes made from different feedstocks. Biotechnol Res Int. 2012;2012(1):165202.

Raj R, Tirkey JV. Techno-economic assessment of sugarcane bagasse pith-based briquette production and performance analysis of briquette feed gasifier-engine system. J Environ Manage. 2023;345:118828.

Repsa E, Kronbergs E, Kronbergs A. Evaluation of biomass briquetting mechanism. Proceedings of the 9th International Scientific and Practical Conference; 2013 Jun 20-22; Rezekne, Latvia. Latvia: Environment Technology Resources; 2013. p. 186-9.

Pattiya A, Suttibak S. Production of bio-oil via fast pyrolysis of agricultural residues from cassava plantations in a fluidised-bed reactor with a hot vapour filtration unit. J Anal Appl Pyrolysis. 2012;95:227-35.

Sheng C, Azevedo JLT. Estimating the higher heating value of biomass fuels from basic analysis data. Biomass Bioenergy. 2005;28(5):499-507.

Akpenpuun TD, Salau RA, Adebayo AO, Adebayo OM, Salawu J, Durotoye M. Physical and combustible properties of briquettes produced from a combination of groundnut shell, rice husk, sawdust and wastepaper using starch as a binder. J Appl Sci Environ Manage. 2020;24(1):171-77.

Tomen WT, Diboma BS, Bot BV, Tamba JG. Physical and combustion properties investigation of hybrid briquettes from tropical Sawdust: Case study of Iroko (Milicia excelsa) and Padouk (Pterocarpus soyauxii). Energy Rep. 2023;9:3177-91.

Epesse Misse S, Brillard A, Mayandyshev P, Brilhac JF, Obonou M. Comparative pyrolysis, combustion, and kinetic modeling of twelve Cameroonian woody biomass. Biomass Conv Bioref. 2022;12:3161-81.

Wang J, Yellezuome D, Zhang Z, Liu S, Lu J, Zhang P, et al. Understanding pyrolysis mechanisms of pinewood sawdust and sugarcane bagasse from kinetics and thermodynamics. Ind Crop Prod. 2022;177:114378.

Allende S, Brodie G, Jacob MV. Energy recovery from sugarcane bagasse under varying microwave-assisted pyrolysis conditions. Bioresour Technol Rep. 2022;20:101283.

Gurtner D, Kresta M, Hupfauf B, Götz P, Nussbaumer R, Hofmann A, et al. Mechanical strength characterisation of pyrolysis biochar from woody biomass. Energy. 2023;285:129366.

Xiao LP, Shi ZJ, Xu F, Sun RC. Hydrothermal carbonization of lignocellulosic biomass. Bioresour Technol. 2012;118:619-23.

El-Sayed SA, Mostafa ME. Pyrolysis characteristics and kinetic parameters determination of biomass fuel powders by differential thermal gravimetric analysis (TGA/DTG). Energy Convers Manag. 2014;85:165-72.

Teixeira MG, Pereira SDPS, Fernandes SA, Silva MJD. Enhancement of levoglucosan production via fast pyrolysis of sugarcane bagasse by pretreatment with Keggin heteropolyacids. Ind Crop Prod. 2020;154:112680.

Somasundaram S, Congo T, Steel KM. High temperature viscoelastic behaviour of sugarcane bagasse char and coal blends: role of oxygen and porosity of char on fluidity reduction. Fuel. 2024;362:130672.

Farias JP, Okeke BC, Avila FDD, Demarco CF, Silva MS, Camargo FADO, et al. Biotechnology process for microbial lipid synthesis from enzymatic hydrolysate of pre-treated sugarcane bagasse for potential bio-oil production. Renew Energy. 2023;205:174-84.

Nguyen TH, Phan HB, Le DD, Nguyen HTT, Tran KN, Nguyen LB, et al. Highly efficient and straightforward conversion of sugarcane bagasse into high value-added chemicals using carbonaceous catalyst in deep eutectic solvent. Biomass Bioenergy. 2024;180:107004.

Manatura K. Inert torrefaction of sugarcane bagasse to improve its fuel properties. Case Stud Therm Eng. 2020;19:100623.

Oyibo MC, Moki EC, Birnin Yauri AU, Raphael IA, Ogundele OA, Dabai MD. Combustion profiles of fuel briquettes produced from alkali treated and untreated sugarcane bagasse. Am J Eng Res. 2020;9(3):268-74.

Raslavičius L. Characterization of the woody cutting waste briquettes containing absorbed glycerol. Biomass Bioenergy. 2012;45:144-51.

Cardozo E, Malmquist A. Performance comparison between the use of wood and sugarcane bagasse pellets in a Stirling engine micro-CHP system. Appl Therm Eng. 2019;159:113945.