Effects of spray drying chicken feather keratin with Arabic gum encapsulation for nutrient supplementation

Main Article Content

Abstract

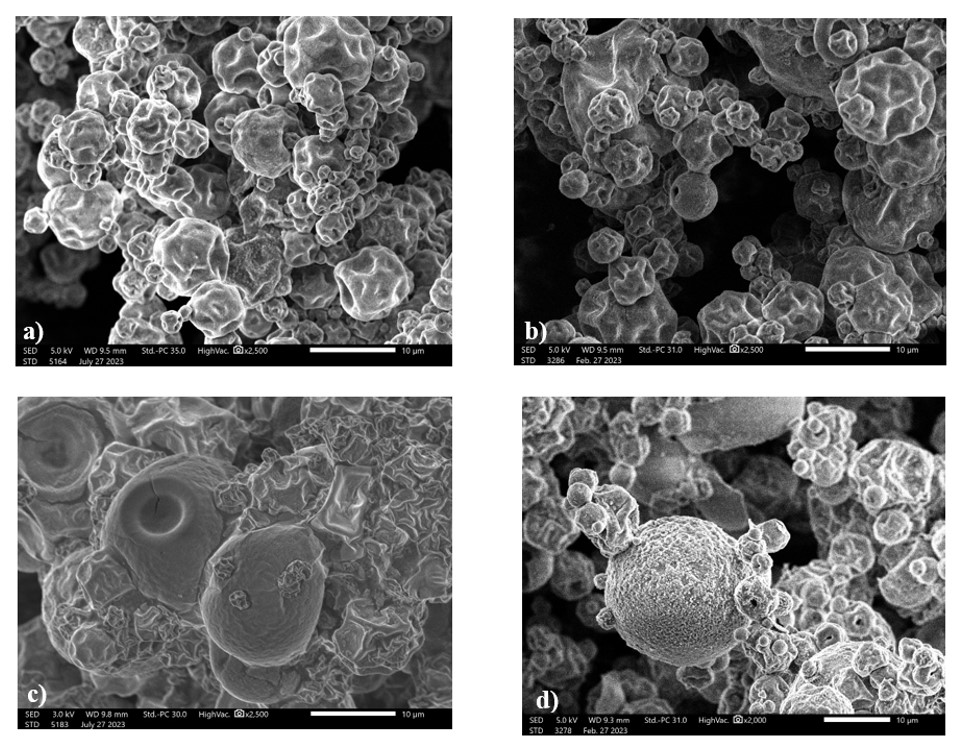

Keratin has always been a topic of interest as a novel protein source in human nutrition, consistent with waste-to-wealth initiatives. Hydrolyzed chicken feather keratin is spray-dried to facilitate storage, transportation, and development into dietary supplements. High-heat drying, however, may affect the quality and function of this bioactive compound. The objective of this research is, thus, to determine the suitable spray-drying parameters involving inlet temperature (70 – 190 °C), feed flow rate (3 – 9 ml/min), and concentration of Arabic gum (AG) (0 – 5%w/v) for the encapsulation of hydrolyzed chicken feather keratin as a nutrient supplement. The effects of the spray-drying on powder yield, moisture content, flowability, and total protein content were investigated. Fourier Transform Infrared Spectroscopy (FTIR) determined the presence of functional groups, while Scanning Electron Microscope (SEM) investigated the powder morphology. High Performance Liquid Chromatography (HPLC) was also conducted to obtain amino acid profiling of the powder. Then, capsule quality control tests were done to ensure compliance with industrial standards. Good powder quality was obtained from the parameters of inlet temperature 190 ± 5°C, feed flow rate of 3 ml/min and AG concentration of 2.50% since it showed high yield of 81.88%, moisture content of 3.74% (<5%), flowability with AOR 43.70° (<50°), high (minimal lost) total protein content of 0.7168 g protein/g solid. The keratin functional groups remain distinguishable through FTIR with AG encapsulation. SEM showed spherical and intact structures, which suggests high integrity of encapsulating materials. Amino acid profiling confirmed the presence of essential and non-essential amino acids, which are important as building blocks of proteins in the body. The product met all capsule quality control standards according to National Pharmaceutical Regulatory Agency of Malaysia (NPRA) and United States Pharmacopeia (USP). This result showed that spray-drying hydrolyzed keratin in the presence of AG would retain its function and powder quality.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

Sinkiewicz I, Śliwińska A, Staroszczyk H, Kołodziejska I. Alternative methods of preparation of soluble keratin from chicken feathers. Waste Biomass Valor. 2017;8(4):1043-8.

Nurkhasanah U, Susanti E, Idris AM, Suharti S. Keratin biofilm from chicken feathers. IOP Conf Ser: Earth Environ Sci. 2020;475:012073.

Pourjavaheri F, Ostovar Pour S, Jones OAH, Smooker PM, Brkljača R, Sherkat F, et al. Extraction of keratin from waste chicken feathers using sodium sulfide and L-cysteine. Process Biochem. 2019;82:205-14.

Ye W, Qin M, Qiu R, Li J. Keratin-based wound dressings: From waste to wealth. Int J Biol Macromol. 2022;211:183-97.

Giteru SG, Ramsey DH, Hou Y, Cong L, Mohan A, Bekhit AEDA. Wool keratin as a novel alternative protein: a comprehensive review of extraction, purification, nutrition, safety, and food applications. Compr Rev Food Sci Food Saf. 2023;22(1):643-87.

Kshetri P, Singh PL, Chanu SB, Singh TS, Rajiv C, Tamreihao K, et al. Biological activity of peptides isolated from feather keratin waste through microbial and enzymatic hydrolysis. Electron J Biotechnol. 2022;60:11-8.

Kamarudin NB, Sharma S, Gupta A, Kee CG, Chik SMSBT, Gupta R. Statistical investigation of extraction parameters of keratin from chicken feather using Design-Expert. 3 Biotech. 2017;7(2):127.

Alahyaribeik S, Ullah A. Effects of ultrasound-assisted alkaline extraction on antioxidant activity and functional characteristics of chicken feather keratin peptides. ChemistrySelect. 2020;5(44):13788-94.

Ma B, Qiao X, Hou X, Yang Y. Pure keratin membrane and fibers from chicken feather. Int J Biol Macromol. 2016;89:614-21.

Sun DS, Lee H, Yim HW, Won HS, Ko YH. The impact of sarcopenia on health-related quality of life in elderly people: Korean National Health and Nutrition Examination Survey. Korean J Intern Med. 2017;34(4):877-84.

Yoshimura Y, Bise T, Shimazu S, Tanoue M, Tomioka Y, Araki M, et al. Effects of a leucine-enriched amino acid supplement on muscle mass, muscle strength, and physical function in post-stroke patients with sarcopenia: a randomized controlled trial. Nutrition. 2019;58:1-6.

Milani M, Colombo F. Efficacy and tolerability of an oral supplement containing amino acids, iron, selenium, and marine hydrolyzed collagen in subjects with hair loss (androgenetic alopecia, AGA or FAGA or telogen effluvium). A prospective, randomized, 3-month, controlled, assessor-blinded study. Skin Res Technol. 2023;29(6):e13381.

Chessa MA, Iorizzo M, Richert B, López-Estebaranz JL, Rigopoulos D, Tosti A, et al. Pathogenesis, clinical signs and treatment recommendations in brittle nails: a review. Dermatol Ther (Heidelb). 2020;10(1):15-27.

Jain KK. An overview of drug delivery systems. In: Jain K, editor. Drug Delivery Systems. Methods in Molecular Biology. New York: Humana Press; 2020. p. 1-54.

Tontul I, Topuz A. Spray-drying of fruit and vegetable juices: effect of drying conditions on the product yield and physical properties. Trends Food Sci Technol. 2017;63:91-102.

Oyinloye TM, Yoon WB. Effect of freeze-drying on quality and grinding process of food produce: a review. Processes. 2020;8(3):354.

Pramudita D, Humjaa S, Tsotsas E. Droplet drying and whey protein denaturation in pulsed gas flow - a modeling study. J Food Eng. 2022;321:110959.

Aragón-Rojas S, Quintanilla-Carvajal MX, Hernández-Sánchez H. Multifunctional role of the whey culture medium in the spray drying microencapsulation of lactic acid bacteria. Food Technol Biotechnol. 2018;56(3):381-97.

Wu G, Hui X, Mu J, Brennan MA, Brennan CS. Functionalization of whey protein isolate fortified with blackcurrant concentrate by spray-drying and freeze-drying strategies. Food Res Int. 2021;141:110025.

Febriyenti F, Mohtar N, Mohamed N, Razak Hamdan M, Najib S, Salleh Md, et al. Comparison of freeze drying and spray drying methods of haruan extract. Int J Drug Deliv. 2014;6:286-91.

Niamnuy C, Poomkokrak J, Dittanet P, Devahastin S. Impacts of spray drying conditions on stability of isoflavones in microencapsulated soybean extract. Dry Technol. 2019;37(14):1844-62.

Wang H, Tong X, Yuan Y, Peng X, Zhang Q, Zhang S, et al. Effect of spray-drying and freeze-drying on the properties of soybean hydrolysates. J Chem. 2020;2020:9201457.

Tay JBJ, Chua X, Ang C, Subramanian GS, Tan SY, Lin EMJ, et al. Effects of spray-drying inlet temperature on the production of high-quality native rice starch. Processes. 2021;9(9):1557.

Čujić-Nikolić N, Stanisavljević N, Šavikin K, Kalaušević A, Nedović V, Bigović D, et al. Application of gum Arabic in the production of spray-dried chokeberry polyphenols, microparticles characterisation and in vitro digestion method. Lekovite Sirovine. 2018;38(1):9-16.

Kalušević AM, Lević SM, Čalija BR, Milić JR, Pavlović VB, Bugarski BM, et al. Effects of different carrier materials on physicochemical properties of microencapsulated grape skin extract. J Food Sci Technol. 2017;54(11):3411-20.

Lucas J, Ralaivao M, Estevinho BN, Rocha F. A new approach for the microencapsulation of curcumin by a spray drying method, in order to value food products. Powder Technol. 2020;362:428-35.

Burnett CL, Bergfeld WF, Belsito DV, Hill RA, Klaassen CD, Liebler DC, et al. Safety assessment of keratin and keratin-derived ingredients as used in cosmetics. Int J Toxicol. 2021;40(2_suppl):36S-51S.

Alcântara MA, de Lima AEA, Braga ALM, Tonon RV, Galdeano MC, da Costa Mattos M, et al. Influence of the emulsion homogenization method on the stability of chia oil microencapsulated by spray drying. Powder Technol. 2019;354:877-85.

Arumugham T, Krishnamoorthy R, AlYammahi J, Hasan SW, Banat F. Spray dried date fruit extract with a maltodextrin/gum arabic binary blend carrier agent system: process optimization and product quality. Int J Biol Macromol. 2023;238:124340.

Agarwal V, Panicker AG, Indrakumar S, Chatterjee K. Comparative study of keratin extraction from human hair. Int J Biol Macromol. 2019;133:382-90.

Badrulzaman SZS, Aminan AW, Ramli ANM, Man RC, Azelee NIW. Extraction and characterization of keratin from chicken and swiftlet feather. Mater Sci Forum. 2021;1025:157-62.

Wei NS, Sulaiman R. Effect of Maltodextrin, Arabic gum, and beetroot juice concentration on the powder properties of spray-dried beetroot-skim milk mixtures. Acta Univ Cibiniensis, Ser E: Food Technol. 2022;26(2):209-24.

The United States Pharmacopeial Convention. 〈1174〉 Powder Flow Stage 4 Harmonization [Internet]. 2016 [cited 2022 Apr 19]. Available from: https://www.usp.org/sites/default/files/usp/document/harmonization/gen-chapter/20230428HSm99885.pdf.

Schneider CA, Rasband WS, Eliceiri KW. NIH Image to ImageJ: 25 years of image analysis. Nat Methods. 2012;9:671-5.

Correâ-Filho LC, Lourenço MM, Moldaõ-Martins M, Alves VD. Microencapsulation of β-Carotene by spray drying: effect of wall material concentration and drying inlet temperature. Int J Food Sci. 2019;2019:8914852.

Akbarbaglu Z, Mahdi Jafari S, Sarabandi K, Mohammadi M, Khakbaz Heshmati M, Pezeshki A. Influence of spray drying encapsulation on the retention of antioxidant properties and microstructure of flaxseed protein hydrolysates. Colloids Surf B Biointerfaces. 2019;178:421-9.

The United States Pharmacopeial Convention. 〈701〉 Disintegration Stage 4 Harmonization. 2020 [cited 2022 Aug 27]. Available from: https://www.usp.org/sites/default/files/usp/document/harmonization/gen-chapter/april-2019-m99460.pdf.

Lyu W, Omar T, Patel H, Rodriguez D, Ferruzzi MG, Pasinetti GM, et al. Dissolution study on grape polyphenol hard gelatin capsule dietary supplements. Front Nutr. 2021;8:780260.

The United States Pharmacopeial Convention. 〈711〉 Dissolution Stage 6 Harmonization [Internet]. 2011 [cited 2023 Feb 21]. Available from: https://www.usp.org/sites/default/files/usp/document/harmonization/gen-method/stage_6_monograph_25_feb _2011.pdf.

Akdeniz B, Sumnu G, Sahin S. The effects of maltodextrin and gum Arabic on encapsulation of onion skin phenolic compounds. Chem Eng Trans. 2017;57:1891-6.

Du W, Zhang L, Zhang C, Cao J, Wang D, Li H, et al. Green and highly efficient wool keratin extraction by microwave induction method. Front Mater. 2022;8:789081.

Guo J, Li P, Kong L, Xu B. Microencapsulation of curcumin by spray drying and freeze drying. LWT. 2020;132:109892.

Premi M, Sharma HK. Effect of different combinations of maltodextrin, gum arabic and whey protein concentrate on the encapsulation behavior and oxidative stability of spray dried drumstick (Moringa oleifera) oil. Int J Biol Macromol. 2017;105:1232-40.

Schlick-Hasper E, Bethke J, Vogler N, Goedecke T. Flow properties of powdery or granular filling substances of dangerous goods packagings—comparison of the measurement of the angle of repose and the determination of the Hausner ratio. Packag Technol Sci. 2022;35(10):765-82.

Shah DS, Moravkar KK, Jha DK, Lonkar V, Amin PD, Chalikwar SS. A concise summary of powder processing methodologies for flow enhancement. Heliyon. 2023;9(6):e16498.

Aguilar-Vázquez G, Loarca-Piña G, Figueroa-Cárdenas JD, Mendoza S. Electrospun fibers from blends of pea (Pisum sativum) protein and pullulan. Food Hydrocoll. 2018;83:173-81.

Dvoryaninova OP, Sokolov AV, Peregonchaya OV, Solovyeva EA, Syanov DA. Identification of composition and structure of functional groups of ferment lysates based on IR spectroscopy. IOP Conf Ser: Earth Environ Sci. 2021;640:032062.

Liya SM, Umesh M. Bioconversion of chicken feather waste into feather hydrolysate by multifaceted keratinolytic Bacillus tropicus LS27 and new insights into its antioxidant and plant growth-promoting properties. Biomass Convers Biorefin. 2023:1-11.

Thombare N, Mahto A, Singh D, Chowdhury AR, Ansari MF. Comparative FTIR characterization of various natural gums: a criterion for their identification. J Polym Environ. 2023;31(8):3372-80.

Farshchi A, Hassanpour A, Ettelaie R, Bayly AE. Evolution of surface micro-structure and moisture sorption characteristics of spray-dried detergent powders. J Colloid Interface Sci. 2019;551:283-96.

Koo SY, Cha KH, Song DG, Chung D, Pan CH. Microencapsulation of peppermint oil in an alginate-pectin matrix using a coaxial electrospray system. Int J Food Sci Technol. 2014;49(3):733-9.

Baiocco D, Preece JA, Zhang Z. Microcapsules with a fungal chitosan-gum Arabic-maltodextrin shell to encapsulate health-beneficial peppermint oil. Food Hydrocoll Health. 2021;1:100016.

Carpentier J, Conforto E, Chaigneau C, Vendeville JE, Maugard T. Complex coacervation of pea protein isolate and tragacanth gum: comparative study with 1 commercial polysaccharides. Innov Food Sci Emerg Technol. 2021;69:102641.

Zuidam NJ, Shimoni E. Overview of microencapsulates for use in food products or processes and methods to make them. In: Zuidam N, Nedovic V, editors. Encapsulation Technologies for Active Food Ingredients and Food Processing. New York: Springer; 2010. p. 3-29.

Cao M, Gao J, Li Y, Liu C, Shi J, Ni F, et al. Complexation of β-lactoglobulin with gum arabic: effect of heat treatment and enhanced encapsulation efficiency. Food Sci Nutr. 2021;9(3):1399-409.

Yeop A, Sandanasamy J, Pang SF, Gimbun J. Stability and controlled release enhancement of Labisia pumila’s polyphenols. Food Biosci. 2021;41:101025.

Rosland Abel SE, Yusof YA, Chin NL, Chang LS, Mohd Ghazali H, Manaf YN. Characterisation of physicochemical properties of gum arabic powder at various particle sizes. Food Res. 2020;4:107-15.

Ćujić N, Šavikin K, Janković T, Pljevljakušić D, Zdunić G, Ibrić S. Optimization of polyphenols extraction from dried chokeberry using maceration as traditional technique. Food Chem. 2016;194:135-42.

Tonon RV, Brabet C, Hubinger MD. Influence of process conditions on the physicochemical properties of açai (Euterpe oleraceae Mart.) powder produced by spray drying. J Food Eng. 2008;88(3):411-8.

Hassan MA, Xavier M, Gupta S, Nayak BB, Balange AK. Antioxidant properties and instrumental quality characteristics of spray dried Pangasius visceral protein hydrolysate prepared by chemical and enzymatic methods. Environ Sci Pollut Res. 2019;26(9):8875-84.

Lopez MJ, Mohiuddin SS. Biochemistry, essential amino acids. Treasure Island (FL): StatPearls Publishing; 2024.

Gupta A, Kamarudin NB, Yeo C, Chua GK, Bin R, Yunus RM. Extraction of keratin protein from chicken feather. J Chem Chem Eng. 2012;6:732-7.

Staroń P, Banach M, Kowalski Z, Staroń A. Hydrolysis of keratin materials derived from poultry industry. Proc ECOpole. 2014;8(2):443-8.

Kamei Y, Hatazawa Y, Uchitomi R, Yoshimura R, Miura S. Regulation of skeletal muscle function by amino acids. Nutrients. 2020;12(1):261.

Lin G, Zhou H, Lian J, Chen H, Xu H, Zhou X. Preparation of pH-responsive avermectin/feather keratin-hyaluronic acid with anti-UV and sustained-release properties. Colloids Surf B Biointerfaces. 2019;175:291-9.

Voinitchi C, Gaidau C, Capatana Tudorie F, Niculescu M, Stanca M, Alexe CA. Collagen and keratin hydrolysates to delay the setting of gypsum plaster. Materials. 2022;15(24):8817.

Chilakamarry CR, Mahmood S, Saffe SNBM, Arifin MAB, Gupta A, Sikkandar MY, et al. Extraction and application of keratin from natural resources: a review. 3 Biotech. 2021;11(5):220.

Daoub RMA, Elmubarak AH, Misran M, Hassan EA, Osman ME. Characterization and functional properties of some natural Acacia gums. J Saudi Soc Agric Sci. 2018;17(3):241-9.

Feroz S, Muhammad N, Dias G, Alsaiari MA. Extraction of keratin from sheep wool fibres using aqueous ionic liquids assisted probe sonication technology. J Mol Liq. 2022;350:118595.

Wang J, Gao H, Qin C, Zhao Z, Yuan H, Wei J, et al. Experimental and theoretical study on the extraction of keratin from human hair using protic ionic liquids. J Mol Liq. 2022;368:120626.

Ministry of Health Malaysia. Appendix 6: Guideline on Registration of Health Supplements [Internet]. 2023 [cited 2023 Dec 20]. Available from: https://www.npra.gov.my/easyarticles/images/users/1047/drgd/APPENDIX-6---Guideline-on-Registration-of-Health-Supplements.pdf.

Bandara SB, Towle KM, Monnot AD. A human health risk assessment of heavy metal ingestion among consumers of protein powder supplements. Toxicol Rep. 2020;7:1255-62.

Bos CE, van Doorne H, Lerk CF. Microbiological stability of tablets stored under tropical conditions. Int J Pharm. 1989;55(2-3):175-83.

Dao H, Lakhani P, Police A, Kallakunta V, Ajjarapu SS, Wu KW, et al. Microbial stability of pharmaceutical and cosmetic products. AAPS PharmSciTech. 2018;19(1):60-78.

Jones BE, Basit AW, Tuleu C. The disintegration behaviour of capsules in fed subjects: a comparison of hypromellose (carrageenan) capsules and standard gelatin capsules. Int J Pharm. 2012;424(1-2):40-3.

US Food and Drug Administration. Notices [Internet]. 2015 [cited 2022 Nov 29] p. 46019. Available from: https://www.govinfo.gov/content/pkg/FR-2015-08-03/pdf/2015-18968.pdf.

Silva DA, Webster GK, Bou-Chacra N, Löbenberg R. The significance of disintegration testing in pharmaceutical development. Dissolut Technol. 2018;25(3):30-8.

US Department of Health and Human Services Food and Drug Administration, Center for Drug Evaluation and Research (CDER). Dissolution testing and acceptance criteria for immediate-release solid oral dosage form drug products containing high solubility drug substances guidance for industry [Internet]. 2018 [cited 2022 Nov 29]. Available from: https://www.fda.gov/files/drugs/published/Dissolution-Testing-and-Acceptance-Criteria-for-Immediate-Release-Solid-Oral-Dosage-Form-Drug-Products-Containing-High-Solubility-Drug-Substances-Guidance-for-Industry.pdf.

Adam DR, Al Rayes N, Fatoum R, Arafeh G, Adam TR, Kola-Mustapha A. Comparative evaluation of amlodipine besylate generic tablet and capsule brands in Riyadh, Saudi Arabia. Dissolut Technol. 2022;29(4):GC9-21.