Comparison of artificial neural network and response surface methodology in predicting the tensile strength and optimization of 3D printed objects

Main Article Content

Abstract

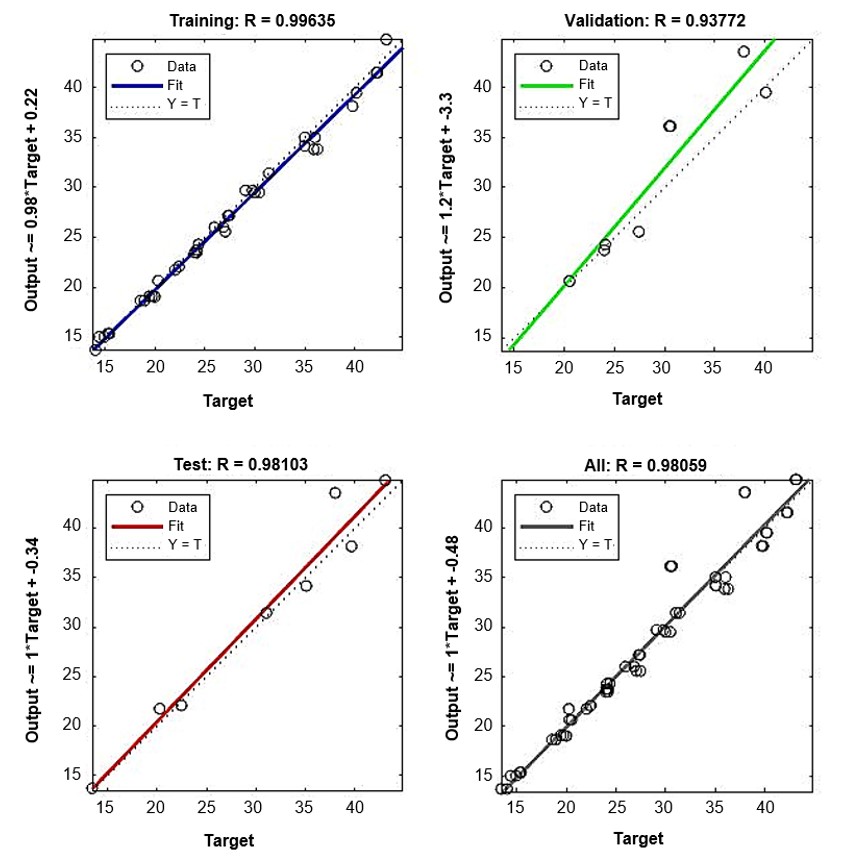

This study investigates the geometric properties of 3D-printed objects using fused deposition modelling. It focuses on optimising parameters for printing in terms of their significant impact on both the quality and cost of printed objects. To enhance the quality of 3D-printed objects, it is crucial to predict the geometric properties in advance. The development of an artificial neural network model (ANN) is employed to predict the tensile strength properties of polylactic acid material during experiments. The model considers three variables: printing temperatures at three levels (190°C, 210°C, and 230°C), printing speeds at three levels (30 mm/s, 50 mm/s, and 70 mm/s), and material infill density at three levels (40%, 60%, and 80%). Tensile strength testing was conducted, and the predictive performance of ANN models was compared with mathematical models derived from the application of response surface methodology (RSM). The goal was to determine suitable printing conditions. Tensile strength testing revealed that printing temperature, printing speed, and infill density significantly impact tensile strength. The ANN configuration consists of a 3-input layer with 3 neurons, a hidden layer with 14 neurons, and an output layer with 1 neuron, denoted as 3-14-1. The model exhibited a testing decision-making accuracy of 0.938. The average error for the ANN model was 0.307, lower than the average error from the full factorial model, which was 1.392. The optimized printing conditions for maximum tensile strength were found to be a print temperature (X1) of 230°C, a feed rate (X2) of 30 mm/sec, and an infill density (X3) of 80%, resulting in a tensile strength of 43.107 MPa. The mathematical model derived from RSM demonstrated efficacy in predicting and controlling the quality of printed objects, aiming to reduce production costs and enhance efficiency in future 3D printing processes.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

Shahrubudin N, Lee TC, Ramlan R. An overview on 3D printing technology: technological, materials, and applications. Procedia Manuf. 2019;35:1286-96.

Kaushik A, Garg RK. Tapping the potential of rapid prototyping techniques in creating a paradigm shift in the fabrication of occlusal splints. Rapid Prototyp J. 2023;29(10):2176-92.

Kumar A, Chhabra D. Adopting additive manufacturing as a cleaner fabrication framework for topologically optimized orthotic devices: implications over sustainable rehabilitation. Clean Eng Technol. 2022;10:100559.

Prater T, Werkheiser N, Ledbetter F, Timucin D, Wheeler K, Snyder M. 3D Printing in Zero G Technology Demonstration Mission: complete experimental results and summary of related material modelling efforts. Int J Adv Manuf Technol. 2019;101(1-4):391-417.

Yadav D, Chhabra D, Gupta RK, Phogat A, Ahlawat A. Modelling and analysis of significant process parameters of FDM 3D printer using ANFIS. Mater Today Proc. 2020;21:1592-604.

Mwema FM, Akinlabi ET. Basics of fused deposition modelling (FDM). In: Mwema FM, Akinlabi ET, editors. Fused deposition modelling: strategies for quality enhancement. Cham: Springer; 2020. p. 1-15.

Sheoran AJ, Kumar H. Fused deposition modelling process parameters optimization and effect on mechanical properties and part quality: review and reflection on present research. Mater Today Proc. 2020;21:1659-72.

Pandžić A, Hodžić D, Kadrić E. Experimental investigation on influence of infill density on tensile mechanical properties of different FDM 3D printed materials. TEM J. 2021;10(3):1195-201.

Wankhede V, Jagetiya D, Joshi A, Chaudhari R. Experimental investigation of FDM process parameters using Taguchi analysis. Mater Today Proc. 2020;27:2117-20.

Algarni M, Ghazali S. Comparative study of the sensitivity of PLA, ABS, PEEK, and PETG’s mechanical properties to FDM printing process parameters. Crystals. 2021;11(8):995.

Milovanović A. Sedmak A, Grbović A, Golubović Z, Mladenović G, Čolić K, et al. Comparative analysis of printing parameters effect on mechanical properties of natural PLA and advanced PLA-X material. Procedia Struct Integr. 2020;28:1963-8.

Mamo HB, Tura AD, Santhosh AJ, Ashok N, Rao DK. Modelling and analysis of flexural strength with fuzzy logic technique for a fused deposition modelling ABS components. Mater Today Proc. 2022;57:768-74.

Wang S, Ma Y, Deng Z, Zhang S, Cai J. Effects of fused deposition modelling process parameters on tensile, dynamic mechanical properties of 3D printed polylactic acid materials. Polym Test. 2020;86:106483.

Akhavan-Safar A, Beygi R, Delzendehrooy F, da Silva LFM. Fracture energy assessment of adhesives—Part I: Is GIC an adhesive property? a neural network analysis. Proc Inst Mech Eng L: J Mater: Des Appl. 2021;235(6):1461-76.

Delzendehrooy F, Beygi R, Akhavan-Safar A, da Silva LFM. Fracture energy assessment of adhesives Part II: Is GIIc an adhesive material property? (a neural network analysis). J Adv Join Process. 2021;3:100049.

Yadav D, Chhabra D, Garg RK, Ahlawat A, Phogat A. Optimization of FDM 3D printing process parameters for multi-material using artificial neural network. Mater Today Proc. 2020;21:1583-91.

Tura AD, Mamo HB, Jelila YD, Lemu HG. Experimental investigation and ANN prediction for part quality improvement of fused deposition modelling parts. IOP Conf Ser: Mater Sci Eng. 2021;1201:012031.

Khan MS, Mishra SB. Minimising surface roughness of ABS-FDM build parts: an experimental approach. Mater Today Proc. 2020;26:1557-66.

Kaushik A, Garg RK. Effect of printing parameters on the surface roughness and dimensional accuracy of digital light processing fabricated parts. J Mater Eng Perform. 2023:1-13.

Kuznetsov VE, Solonin AN, Urzhumtsev OD, Schilling R, Tavitov AG. Strength of PLA components fabricated with fused deposition technology using a desktop 3D printer as a function of geometrical parameters of the process. Polymers. 2018;10(3):313.

Dave HK, Prajapati AR, Rajpurohit SR, Patadiya NH, Raval HK. Investigation on tensile strength and failure modes of FDM printed part using in-house fabricated PLA filament. Adv Mater Process Technol. 2022;8(1):576-97.

Pérez M, Medina-Sánchez G, García-Collado A, Gupta M, Carou D. Surface quality enhancement of fused deposition modelling (FDM) printed samples based on the selection of critical printing parameters. Materials. 2018;11(8):1382.

Naveed N. Investigate the effects of process parameters on material properties and microstructural changes of 3D-printed specimens using fused deposition modelling (FDM). Mater Technol. 2021;36(5):317-30.

Dong G, Wijaya G, Tang Y, Zhao YF. Optimising process parameters of fused deposition modelling by Taguchi method for the fabrication of lattice structures. Addit Manuf. 2018;19:62-72.

ASTM. ASTM D638-14: Standard test methods for tensile properties of plastics. West Conshohocken: ASTM International; 2014.

Goldberg Y. Neural network methods for natural language processing. Cham: Springer; 2017.

Myers RH, Montgomery DC. Response surface methodology process and product optimization using designed experiments. 2nd ed. Hoboken: John Wiley and Sons; 2002.

Naveed N. Investigating the material properties and microstructural changes of fused filament fabricated PLA and Tough-PLA parts. Polymers. 2021;13(9):1487.

Moradi M, Aminzadeh A, Rahmatabadi D, Hakimi A. Experimental investigation on mechanical characterisation of 3D printed PLA produced by fused deposition modelling (FDM). Mater Res Express. 2021;8:035304.

Vidakis N, Petousis M, Karapidakis E, Mountakis N, David C, Sagris D. Energy consumption versus strength in MEX 3D printing of polylactic acid. Adv Ind Manuf Eng. 2023;6:100119.

Shirzad M, Zolfagharian A, Matbouei A, Bodaghi M. Design evaluation and optimization of 3D printed truss scaffolds for bone tissue engineering. J Mech Behav Biomed Mater. 2021;120:104594.