Mechanical and wear behaviour of boron carbide fillers reinforced Lapox L-12 epoxy composites

Main Article Content

Abstract

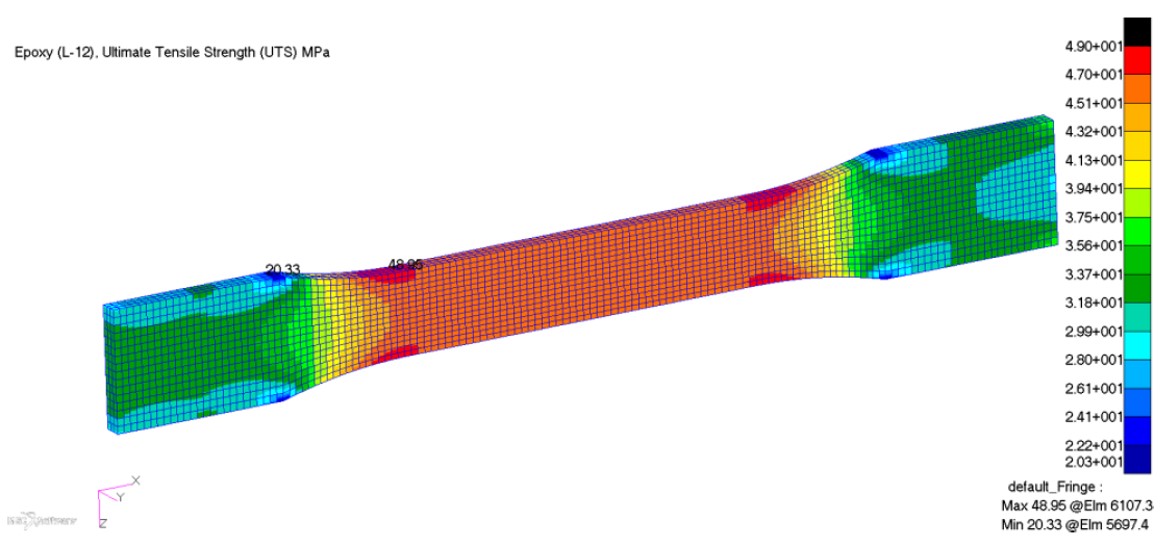

To keep up with the growing demand for composites in fields like medicine, transportation, safety, and athletics, researchers constantly create new composites. These experiments examined the impact of boron carbide filler particles in epoxy by making composites out of Lapox L-12 epoxy with 5, 10, and 15 percent boron carbide fillers using the hand layup technique. The mechanical properties of the prepared composites were measured as per ASTM standards, including hardness, ultimate tensile strength, yield strength, elongation, and flexural strength. Further, wear behavior of prepared composites was evaluated as ASTM G99 standard with varying loads and speeds. Hardness, tensile and flexural strength were increased with a slight decrease in percentage elongation after boron carbide filler particles were added to epoxy Lapox L-12. Lapox L-12 with boron carbide fillers reinforced composites were shown an improvement of 56.4% in hardness, 52.5% in ultimate strength and 25.85% improvements in the flexural strength. The wear behaviour of epoxy and its composites were affected by applied load and speeds. However, Lapox L-12 with boron carbide fillers reinforced composites exhibits higher wear resistance with smooth worn surface morphologies. The improvement in the tensile and wear behavior of L-12 epoxy with B4C composites can be utilized for several applications like air intake duct and air intake lip of an aircraft.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

Maharramov AM, Ramazanov MA, Ahmadova AB, Hajiyeva FV, Hasanova UA. Thermal and mechanical properties of polymer-based nanocomposites of isotactic polypropylene and titanium nanoparticles. Digest J Nanomater Biostruct. 2016;11(2):365-72.

Lee GW, Park M, Kim J, Lee JI, Yoon HG. Enhanced thermal conductivity of polymer composites filled with hybrid filler. Compos A: Appl Sci Manuf. 2006;37(5):727-34.

Krishna Prasad S, Dayanand S, Rajesh M, Nagaral M, Auradi V, Selvaraj R. Preparation and mechanical characterization of TiC particles reinforced Al7075 alloy composites. Adv Mater Sci Eng. 2022;2022(1):7105189.

Rezaur Rahman Md, Hasan M, Monimul Huque Md, Nazrul Islam Md. Physico-mechanical properties of jute fiber reinforced polypropylene composites. J Reinf Plast Compos. 2010;29(3):445-55.

Yadav PS, Purohit R, Kothari A. Effect of nano SiO2 on the mechanical and tribological properties of hybrid polymer matrix composites: a review. Adv Mater Manuf Charact. 2017;7(2):101-10.

Raksha MS, Basavalingappa A, Nagaral M, Anjinappa C, Omprakash B, Razak A, et al. Impact of micro graphite particles addition on the mechanical behavior of Al2011 alloy metal composites. Eng Rep. 2024;6(4):e12746.

Jani SP, Kumar AS, Khan MA, Sajith S, Saravanan A. Influence of natural filler on mechanical properties of hemp/kevlar hybrid green composite and analysis of change in material behavior using acoustic emission. J Nat Fibers. 2021;18(11):1580-91.

Kambaiah R, Suresh R, Nagaral M, Auradi V, Anjinappa C, Garse K, et al. Mechanical‐wear behavior and microstructure analysis of Al2214 alloy with B4C and graphite particles hybrid composites. Eng Rep. 2024:e12876.

Jothi AS, Saravanan R. Study on filler reinforcement in polymer matrix composites – a review. Mater Today: Proc. In press 2023.

Markandan K, Lai CQ. Fabrication, properties and applications of polymer composites additively manufactured with filler alignment control: a review. Compos B Eng. 2023;256:110661.

Nalaeram Sivaram R, Kumar Thiagamani SM, Sivakumar P, Srinivasan M, Boyina Yagna SN, Hossein EK, et al. Isolation and characterization of agro waste biomass sapodilla seeds as reinforcement in potential polymer composite applications. Heliyon. 2023;9(7):e17760.

Lal LPJ, Ramesh S, Natarajan E. Study on the repeatability of manufacturing nano-silica (SiO2) reinforced composite laminates. IOP Conf Ser: Mater Sci Eng. 2018;346(1):012083.

Drzal LT, Mohanty AK, Misra M. Bio-composite materials as alternatives to petroleum-based composites for automotive applications. Magnesium. 2001;40:1-8.

Shen XJ, Pei XQ, Liu Y, Fu SY. Tribological performance of carbon nanotube-graphene oxide hybrid/epoxy composites. Compos B Eng. 2014;57:120-5.

Nagaral M, Kalgudi S, Auradi V, Kori SA. Mechanical characterization of ceramic nano B4C-Al2618 alloy composites synthesized by semi solid state processing. Trans Indian Ceram Soc. 2018;77(3):146-9.

Vasanth Kumar HS, Kempaiah UN, Nagaral M, Revanna K. Investigations on mechanical behaviour of micro B4C particles reinforced Al6061 alloy metal composites. Indian J Sci Technol. 2021;14(22):1855-63.

Ali Z, Muthuraman V, Rathnakumar P, Gurusamy P, Nagaral M. Studies on mechanical properties of 3 wt% of 40 and 90 µm size B4C particulates reinforced A356 alloy composites. Mater Today: Proc. 2022;52:494-9.

Murthy BV, Auradi V, Nagaral M, Vatnalmath M, Namdev N, Anjinappa C, et al. Al2014–alumina aerospace composites: particle size impacts on microstructure, mechanical, fractography, and wear characteristics. ACS Omega. 2023;8(14):13444-55.

Nagaral M, Shivananda BK, Auradi V, Kori SA. Development and mechanical-wear characterization of Al2024-nano B4C composites for aerospace applications. Strength Fract Complex. 2020;13(1):1-13.

Bharath V, Ashita DH, Auradi V, Nagaral M. Influence of variable particle size reinforcement on mechanical and wear properties of alumina reinforced 2014Al alloy particulate composite. FME Trans. 2020;48(4):968-78.

Kumar R, Deshpande RG, Gopinath B, Harti J, Nagaral M, Auradi V. Mechanical fractography and worn surface analysis of nanographite and ZrO2-reinforced Al7075 alloy aerospace metal composites. J Fail Anal Prev. 2021;21:525-36.

Nagaral M, Auradi V, Kori SA, Reddappa HN, Jayachandran, Shivaprasad V. Studies on 3 and 9 wt. % of B4C particulates reinforced Al7025 alloy composites. AIP Conf Proc. 2017;1859(1):020019.

Dilip Kumar K, Shantharaja M, Kiran MD, Rajesh M, Kumar N, Lenin H. Tribological characterization of epoxy hybrid composites reinforced with Al2O3 nanofiller. Adv Mater Sci Eng. 2023;2023:8196933.

Arjmandi R, Hassan A, Majeed K, Zakaria Z. Rice husk filled polymer composites. Int J Polym Sci. 2015;2015:501471.

Bhatia S, Angra S, Khan S. A review on mechanical and tribological characterization of boron carbide reinforced epoxy composite. Adv Compos Mater. 2021;30(4):307-37.

Abenojar J, Martínez MA, Velasco F, Pascual-Sanchez V, Martín-Martínez JM. Effect of boron carbide filler on the curing and mechanical properties of an epoxy resin. J Adhes. 2009;85(4-5):216-38.

Abenojar J, del Real JC, Martinez MA, Cano de Santayana M. Effect of silane treatment on SiC particles used as reinforcement in epoxy resins. J Adhes. 2009;85(6):287-301.

Pati PR, Satpathy MP. Investigation on red brick dust filled epoxy composites using ant lion optimization approach. Polym Compos. 2019;40(10):3877-85.

Ganesh R, Anand P. Experimental investigation on mechanical properties of Basalt/Jute/SiC reinforced hybrid polymer composites. Mater Today Proc. 2022;59:1636-42.

Fazil N, Venkataraman V, Nagaral M. Mechanical characterization and wear behavior of aerospace alloy AA2124 and micro B4C reinforced metal composites. J Met Mater Miner. 2020;30(4):97-105.

Pramanik A. Effects of reinforcement on wear resistance of aluminium composite. Trans Nonferrous Met Soc China. 2016;26(2):348-58.