Mathematical analysis of scaled-size clinker bed for temperature and pressure drop evaluation

Main Article Content

Abstract

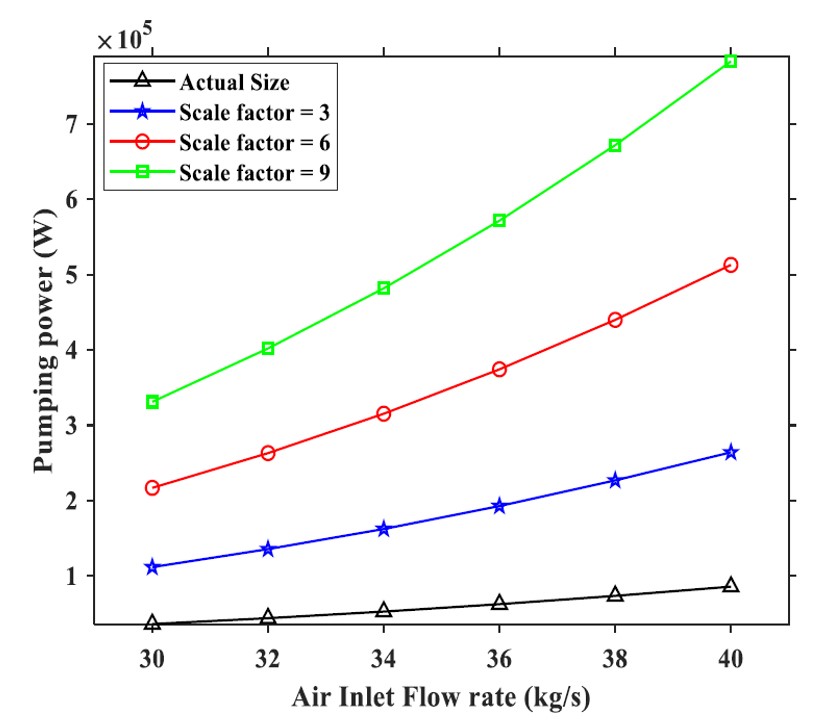

In order to leverage on existing scaling methodologies, clinker bed was investigated to evaluate its performance for scaled down sizes. Small-sized clinker bed will provide cheaper and faster means of carrying out performance optimization study of clinker cooling process, which has been a research focus in recent years. Heat transfer mathematical equations were adopted to determine the outlet’s temperatures and air pressure drop across the clinker bed, while Buckingham Pi theorem was employed to perform the scaling down of the clinker bed. Findings from the study revealed that for the actual size, predicted air outlet temperature, when compared to the experimental and numerical simulation results from existing literature, produced deviation of –5.46% and +1.65% respectively. For the scaled down-sizes, the air outlet temperature when compared with the actual size of experimental result, yielded deviations of 3.96%, 5.77% and 4.9% because the scaled sizes have 3, 6 and 9 scale factors, respectively. The results further revealed that an increase in mass flow rate of air will improve the heat transfer performance of the clinker bed, but this comes with an increase in pressure drop across the clinker bed heights. Furthermore, an increase in clinker flow rate was observed to be undesirable because the clinker outlet temperature actually being expected to cool down eventually increases, although pressure drop remained unchanged. By adopting a thermal-hydraulic performance factor, maximum percentage deviation between of the actual size and each scaled size was 0.08% which indicates negligible performance deviation. The study therefore reveals that the size of clinker bed can be reduced to enable the development of small-scale prototype, and for numerical simulation to optimize the cooling process, especially when the outlet temperature and air pressure drop are the primary targets of investigation.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

Shao W, Chen X, Zhao T, Chen Q. Heat current model of solid granule cooling processes in moving packed beds and its applications. Chem Eng Res Des. 2020;156:384-90.

John JP. Parametric studies of cement production processes. J Energy. 2020;2020:1-17.

Hanein T, Glasser FP, Bannerman MN. Thermodynamics data for cement clinkering. Cem Concr Res. 2020;132:106043.

Alsop PA. The cement plant operations handbook. 7th ed. Dorking: Tradeship Publications Ltd.; 2019.

Cao Q, Zheng C, Sun Q, Cheng L. Numerical simulation of an improved structure for high-resistance grate plates. Energy Procedia. 2016;104:407-12.

Okoji AI, Anozie AN, Omoleye JA, Osuolale FN. Thermodynamics and parametric study of the grate clinker cooler using the process model. IOP Conf. Ser: Mater Sci Eng. 2021;1107:012189.

Shao W, Cui Z, Cheng L. Multi-objective optimization design of air distribution of grate cooler by entropy generation minimization and genetic algorithm. Appl Therm Eng. 2016;108:76-83.

Shao W, Cui Z, Cheng L. Multi-objective optimization of cooling air distribution of grate cooler with different clinker particles diameters and air chambers by genetic algorithm. Appl Therm Eng. 2017;111:77-86.

Cui Z, Shao W, Chen Z, Cheng L. Mathematical model and numerical solutions for the coupled gas–solid heat transfer process in moving packed beds. Appl Energy. 2017;206:1297-308.

Shao W, Cui Z, Ma XT. Experimental research on cement grate cooler system and numerical simulation of its clinker cooling process. Appl Therm Eng. 2020;181:115904.

Wang M, Liu B, Wen Y, Liu H. Numerical simulation and analytical characterization of heat transfer between cement clinker and air in grate cooler. J Chem Eng Jpn, 2016;49(1):10-5.

Wang M, Liu B, Wen Y, Liu H. Seepage heat transfer between clinker and cooling air with variable properties in grate cooler. Heat Transf Res. 2017;48(3):263-81.

Yao Y, Ding S, Chen Y. Modeling of the thermal efficiency of a whole cement clinker calcination system and its application on a 5000 MT/D production line. Energies. 2020;13(20):5257.

Abdul W, Rößler C, Mawalala C, Pisch A, Hanein T, Bannerman M. Thermodynamic modeling of Portland cement clinkers. The 16th International Congress on the Chemistry of Cement 2023 (ICCC2023); 2023 Sep 18-22; Bangkok, Thailand. Bangkok: Thailand Concrete Association; 2023. p. 1-4.

Okoji AI, Anozie AN, Omoleye JA. Evaluating the thermodynamic efficiency of the cement grate clinker cooler process using artificial neural networks and ANFIS. Ain Shams Eng J. 2022;13(5):101704.

Kumar DS. Heat and mass transfer. 7th revised ed. New Delhi: S.K. Kataria & Sons; 2010.

Coutinho CP, Baptista AJ, Rodrigues JD. Reduced scale models based on similitude theory: a review up to 2015. Eng Struct. 2016;119:81-94.

Altun O, Wolniak P, Mozgova I, Lachmayer R. An analysis of scaling methods for structural components in the context of size effects and nonlinear phenomena. Proceedings of the Design Society: DESIGN Conference. 2020;1:797-806.

Yoon J, Kim Y, Song H. Numerical and experimental analysis of thermal-flow characteristics in a pyrolysis reactor of a gas scrubber designed based on similitude theory. J Air Waste Manag Assoc. 2020;70(5):532-43.

Douglas JF, Gasiorek JM, Swaffield JA, Jack LB. Fluid mechanics. 5th ed. Pearson Education Limited; 2005.

Casaburo A, Petrone G, Franco F, Rosa SD. A review of similitude methods for structural engineering. Appl Mech Rev. 2019;71(3):1-32.

Kenan H, Azeloğlu O. Design of scaled down model of a tower crane mast by using similitude theory. Eng Struct. 2020;220:110985.

Zhang D, Gao P, Zhou Y, Wang Y, Zhou G. An experimental and numerical investigation on temperature profile of underground soil in the process of heat storage. Renew Energy. 2020;148:1-21.

Zhou LL, Li DK. Design of scaled model for dynamic characteristics of stiffened cylindrical shells based on equivelent similar method. Aeronaut J. 2019;123(1261):398-415.

Fallico C, Lauria A, Aristodemo F. Porous medium typology influence on the scaling laws of confined aquifer characteristic parameters. Water. 2020;12(4):1166.

Oyepata JS, Akintunde MA, Dahunsi OA, Yaru SS, Idowu ET. Modelling of clinker cooler and evaluation of its performance in clinker cooling process for cement plants. Niger J Technol.2020;39(4):1093-9.

Touil D, Belabed HF, Frances C, Belaadi S. Heat exchange modeling of a grate clinker cooler and entropy production analysis. Int J Heat Technol. 2005;23(1):61-8.

Shao W, Cui Z, Liu Y. Multi-objective optimization on clinker layer thickness of a grate cooler based on entropy generation. Energy Procedia. 2019;158:5811-6.

Ma X, Cao Q, Cui Z. Optimization design of the grate cooler based on the power flow method and genetic algorithms. J Therm Sci. 2020;29:1617-26.

Shao W, Cui Z, Cheng L. Multi-objective optimization of cooling air distributions of grate cooler with different inlet temperatures by using genetic algorithm. Sci China Technol Sci. 2017;60:345-54.

Yin HC, Zhu YS, Li DF. Numerical simulation and research of grate cooler based on coupled gas-solid heat transfer. J Therm Sci Technol. 2012;3:229-33.

Liu B, Wang M, Wen Y, Hao X, Fan X. Research on control mechanism model of grate cooler based on seepage heat transfer theory. J Comput Inf Syst. 2013;9(20):8281-8.

Poling BE, Prausnitz JM, O’Connell JP. The properties of gases and liquids. 5th ed. New York: McGraw – Hill; 2020.

Batul B, Sohail A, Aizaz A, Jamil Z. Application of structural similitude for scaling of a pressure vessel. IOP Conf Ser: Mater Sci Eng. 2019;642:012004.

Chen K, Wu W, Yuan F, Chen L, Wang S. Cooling efficiency improvement of air-cooled battery thermal management system through designing the flow pattern. Energy. 2019;167:781-90.

Mogaji TS, Olapojoye AO, Idowu ET, Saleh B. CFD study of heat transfer augmentation and fluid flow characteristics of turbulent flow inside helically grooved tubes. J Braz Soc Mech Sci Eng. 2022;44:90.

Moghadasi H, Bayat M, Aminian E, Hattel JH, Bodaghi M. Computational fluid dynamics study of laminar forced convection improvement of a non-newtonian hybrid nanofluid within an annular pipe in porous media. Energies. 2022;15(21):8207.