Enhancing Lean-Kaizen practices through IoT and automation: A comprehensive analysis with simulation modeling in the Thai food industry

Main Article Content

Abstract

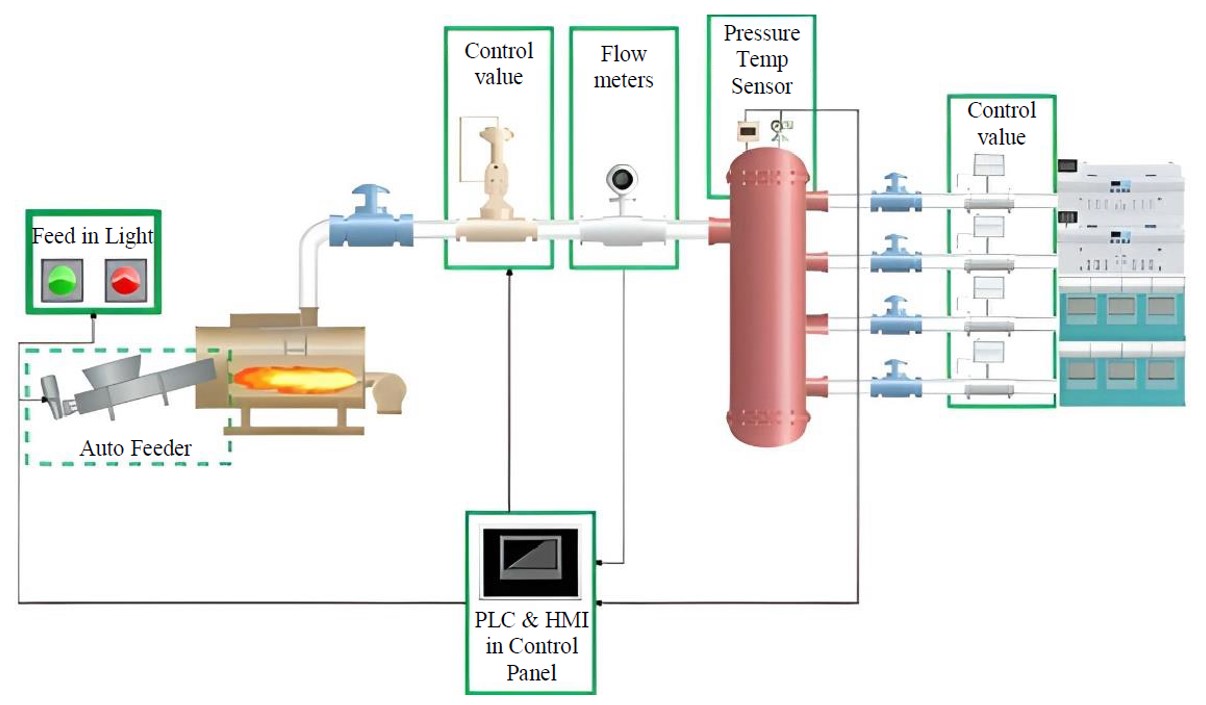

This research delves into a comprehensive examination of the noodle production process within the Thai food industry, focusing on pivotal challenges related to quality control during steaming, weighing, sealing, and vacuum packaging. In response to these challenges, our study investigates the strategic integration of Internet of Things (IoT) and automation solutions to amplify production efficiency. Employing advanced plant simulation tools, including lean manufacturing and Kaizen principles, coupled with methodologies like value stream mapping and flow process charts, we explore four distinct improvement scenarios. Scenario 1 targets enhancements in the dough-baking system during the steaming process, while Scenario 2 concentrates on optimizing the boiler control system. Scenario 3 addresses the weighing and packing process, and Scenario 4 aims at automating the packing process. These scenarios collectively showcase substantial reductions in cycle time, labor costs, and improvements in production capacity. The research design spans a 30-day data collection period, capturing critical metrics related to cycle time, changeover time, workforce, lead time, value-added time, and inventory levels. The gathered data unveils inefficiencies and challenges within the noodle production process, offering a foundation for identifying bottlenecks and areas for enhancement. The study's outcomes underscore the efficacy of technology-driven solutions in addressing production challenges and boosting operational efficiency. Specifically, Scenario 1 and Scenario 4, integrating IoT technology and automation, exhibit a remarkable 7.8% increase in productivity with a one-year payback period. Meanwhile, Scenario 3 significantly reduces labor costs and enhances overall efficiency. These findings contribute to the broader industry discourse, emphasizing the transformative potential of technology-driven solutions in addressing key production challenges and advancing operational excellence. The research provides valuable insights for practitioners seeking innovative approaches to enhance their processes and embrace Industry 4.0 advancements.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

Maroli A, Narwane VS, Gardas BB. Applications of IoT for achieving sustainability in agricultural sector: a comprehensive review. J Environ Manag. 2021;298:113488.

da Costa TP, Gillespie J, Cama-Moncunill X, Ward S, Condell J, Ramanathan R, et al. A systematic review of real-time monitoring technologies and its potential application to reduce food loss and waste: key elements of food supply chains and IoT technologies. Sustainability. 2023;15(1):614.

Heema R, Sivaranjani S, Gnanalakshmi KS. An insight into the automation of the dairy industry: a review. Asian J Dairy Food Res. 2022;41(2):125-31.

Zúñiga ER, Moris MU, Syberfeldt A, Fathi M, Rubio-Romero JC. A simulation-based optimization methodology for facility layout design in manufacturing. IEEE Access. 2020;8:163818-28.

Maware C, Okwu MO, Adetunji O. A systematic literature review of lean manufacturing implementation in manufacturing-based sectors of the developing and developed countries. Int J Lean Six Sigma. 2022;13(3):521-56.

Ortiz ORD, Cárdenas GAM. Kaizen methodology: literature review and implementation analysis. J Sci Technol Res Ind. 2022;3(2):26-35.

Rejeb A, Simske S, Rejeb K, Treiblmaier H, Zailani S. Internet of things research in supply chain management and logistics: a bibliometric analysis. Internet of Things. 2020;12:100318.

Firouz MS, Mohi-Alden K, Omid M. A critical review on intelligent and active packaging in the food industry: research and development. Food Res Int. 2021;141:110113.

Jiang W. An intelligent supply chain information collaboration model based on Internet of Things and big data. IEEE Access. 2019;7:58324-35.

Abdelmegid MA, González VA, O’Sullivan M, Walker CG, Poshdar M, Alarcón LF. Exploring the links between simulation modeling and construction production planning and control: a case study on the last planner system. Prod Plan Control. 2023;34(5):459-76.

Tyagi T, Kumar S, Malik AK, Vashisth V. A novel neuro-optimization techniques for inventory models in manufacturing sectors. J Comput Cogn Eng. 2023;2(3):204-9.

Liu L, Zhao T, Xie Y, Qiu X, Liu S, Wei S, et al. Research on production simulation and bottleneck identification for intelligent printing plant. J Imaging Sci Technol. 2023;67(2):1-7.

Issa TN. Implementing lean-kaizen for manufacturing operations improvement: a case-study in the plastics industry. Int J Ind Syst Eng. 2023;44(1):118-39.

Maware C, Okwu MO, Adetunji O. A systematic literature review of lean manufacturing implementation in manufacturing-based sectors of the developing and developed countries. Int J Lean Six Sigma. 2022;13(3):521-56.

Abbasi R, Martinez P, Ahmad R. The digitization of agricultural industry–a systematic literature review on agriculture 4.0. Smart Agric Technol. 2022;2:100042.

Bigliardi B, Bottani E, Filippelli S. A study on IoT application in the Food Industry using Keywords Analysis. Procedia Comput Sci. 2022;200:1826-35.

Wang J, Qu Z. Design of intelligent weighing and picking system based on sensing technology. Acad J Manag Soc Sci. 2023;2(3):86-9.

Caldwell DG. Automation in food manufacturing and processing. In: Nof SY, editor. Springer Handbook of Automation. Cham: Springer; 2023. p. 949-71.

Nshirim ES, Nwagwu U. Integrated approach for process improvement: value engineering, lean methodology, SIPOC, and value stream mapping. Int J Appl Nat Sci. 2023;1(1):58-66.

Wang CN, Chau Vo TTB, Chung YC, Amer Y, Truc Doan LT. Improvement of manufacturing process based on value stream mapping: a case study. Eng Manag J. 2023:1-19.

Adeleke I, Nwulu N, Adebo OA. Internet of Things (IoT) in the food fermentation process: a bibliometric review. J Food Process Eng. 2023;46(5):e14321.

Wójcicki K, Biegańska M, Paliwoda B, Górna J. Internet of Things in industry: research profiling, application, challenges and opportunities—a review. Energies. 2022;15(5):1806.

Seetha J, Senthil Kumar S, Nruthya K, Rao NKK, Leela Rani D. Enhancement of agriculture productivity and automation of agriculture using IoT. 2023 International Conference on Inventive Computation Technologies (ICICT); 2023 Apr 26-28; Lalitpur, Nepal. USA: IEEE; 2023. p. 1411-7.

Dinlersoz E, Wolf Z. Automation, labor share, and productivity: plant-level evidence from U.S. manufacturing. Econ Innov New Technol. 2023:1-23.

Silitonga RM, Jou YT, Lin MC. Reducing defect products in instant noodles production with Six Sigma. AIP Conf Proc. 2023;2485:120016.

Ito T, Abd Rahman MS, Mohamad E, Abd Rahman AA, Salleh MR. Internet of things and simulation approach for decision support system in lean manufacturing. J Adv Mech Des Syst Manuf. 2020;14(2):1-12.