Analysis of knowledge and skills essential for industrial engineers in context of Industry 4.0 within Thai automobile sector

Main Article Content

Abstract

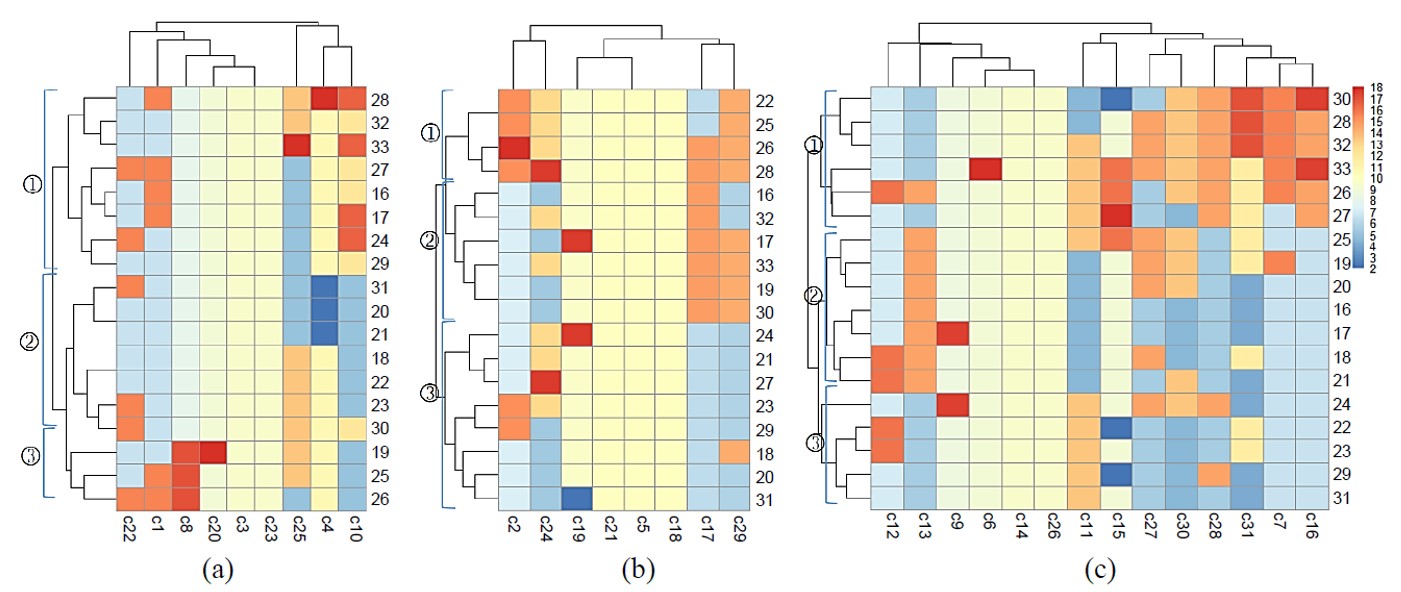

Industry 4.0 has rapidly transformed traditional industries and manufacturing processes by seamlessly integrating digital technologies, automation, data analytics, and the Internet of Things. It represents a profound shift in business operations, emphasizing efficiency, flexibility, and responsiveness to customers. As a result, the required knowledge and skills are evolving for all relevant personnel including industrial engineers (IEs), to achieve success in the Industry 4.0 era. Preparing a capable IE workforce to meet these changing demands is a persistent challenge, particularly in a rapidly evolving environment. This study aims to identify the needs of Thai automobile companies regarding the knowledge and skills of IEs for Industry 4.0. Furthermore, it aims to rank these IE knowledge and skills in terms of importance. In this study, a questionnaire was developed and used as a tool for the research. Respondents representing 31 companies in the Thai automobile industry were asked to rate the importance of each knowledge area and skill. Questions in the knowledge section were divided into 15 knowledge areas across four categories: core subjects, global subjects, engineering subjects, and technological fundamentals. The questions in the skill section were divided into 18 skills spanning five categories: communication, system thinking, creative thinking/ adaptation/ decision-making, learning, and technical proficiency. There are also 12 questions asking respondents to evaluate their level of Industry 4.0 adoption. The findings indicate that the importance rankings for essential IE knowledge and skills vary across a distinct group of Industry 4.0 adoption levels. The rankings of vital IE knowledge and skills across these diverse adoption levels are comparatively analyzed and discussed. While this study primarily centers on the automotive industry, it has the potential to illuminate broader trends that extend to other sectors as well.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

Filos E. Manufacturing innovation and horizon 2020. In: Kovács GL, Kochan D, editors. Digital product and process development systems. Berlin: Springer; 2013. p. 36-40.

Kang HS, Lee JY, Choi S, Kim H, Park JH, Son JY, et al. Smart manufacturing: past research, present findings, and future directions. Int J Precis Eng Manuf – Green Technol. 2016;3:111-28.

Erol S, Jäger A, Hold P, Ott K, Sihn W. Tangible Industry 4.0: a scenario-based approach to learning for the future of production. Procedia CIRP. 2016;54:13-8.

Kagermann H. Change through digitization—value creation in the age of Industry 4.0. In: Albach H, Meffert H, Pinkwart A, Reichwald R, editors. Management of Permanent Change. Wiesbaden: Springer Gabler; 2015. p. 23-45.

Qin J, Liu Y, Grosvenor R. A categorical framework of manufacturing for Industry 4.0 and beyond. Procedia CIRP. 2016;52:173-8.

Sackey SM, Bester A. Industrial engineering curriculum in Industry 4.0 in a South African context. S Afr J Ind Eng. 2016;27(4):101-14.

da Silva ER, Shinohara AC. Nielsen CP, de Lima EP, Angelis J. Operating digital manufacturing in Industry 4.0: The role of advanced manufacturing technologies. Procedia CIRP. 2020;93:174-9.

Hernández-Muñoz GM, Habib-Mireles L, García-Castillo FA, Montemayor-Ibarra F. Industry 4.0 and engineering education: an analysis of nine technological domains inclusion in higher educational curriculum. In: García Alcaraz J, Rivera Cadavid L, González-Ramírez R, Leal Jamil G, Chong Chong M, editors. Best Practices in Manufacturing Processes. Cham: Springer; 2019. p. 525-43.

Jones M, Zarzycki L, Murray G. Does Industry 4.0 pose a challenge for the SME machine builder? a case study and reflection of readiness for a UK SME. In: Ratchev S, editor. Precision Assembly in the Digital Age. IFIP Advances in Information and Communication Technology. Cham: Springer; 2019. p. 183-97.

Khan WZ, Rehman MH, Zangoti HM, Afzal MK, Armi N, Salah K. Industrial internet of things: recent advances, enabling technologies and open challenges. Comput Electr Eng. 2020;81:1-13.

Pacchini APT, Lucato WC, Facchini F, Mummolo G. The degree of readiness for the implementation of Industry 4.0. Comput Ind. 2019;113:1-8.

Saucedo-Martínez JA, Pérez-Lara M, Marmolejo-Saucedo JA, Salais-Fierro TE, Vasant P. Industry 4.0 framework for management and operations: a review. J Ambient Intell Human Comput. 2018;9:789-801.

Vrchota J, Pech M. Readiness of enterprises in Czech Republic to implement Industry 4.0: index of Industry 4.0. Appl Sci. 2019;9(24):1-25.

Castro HF, Carvalho ARF, Leal F, Gouveia H. Assessing Industry 4.0 readiness of Portuguese companies. In: Almeida H, Vasco J, editors. Progress in Digital and Physical Manufacturing (ProDPM 2019). Lecture Notes in Mechanical Engineering. Cham: Springer; 2019. p. 57-64.

Maisiri W, van Dyk L. Industry 4.0 readiness assessment for South African industries. S Afr J Ind Eng. 2019;30(3):134-48.

Rakic S, Pavlovic M, Marjanovic U. A precondition of sustainability: Industry 4.0 readiness. Sustainability. 2021;13(12):1-12.

Todorovic T, Lalic B, Majstorovic V, Marjanovic U, Tasic N. General readiness assessment of Industry 4.0: evidence from Serbian manufacturing industry. In: Lalic B, Majstorovic V, Marjanovic U, von Cieminski G, Romero D, editors. Advances in Production Management Systems. The Path to Digital Transformation and Innovation of Production Management Systems, IFIP Advances in Information and Communication Technology. Cham: Springer; 2020. p. 139-46.

VDMA (Mechanical Engineering Industry Association). IMPULS: Industrie 4.0 readiness [Internet]. 2016 [cited 2021 Apr 11]. Available from: http://sf-eu.net/wp-content/uploads/2016/08/vdma-2015-industrie-4.0-readiness-en.pdf.

Hizam-Hanafiah M, Soomro MA, Abdullah NL. Industry 4.0 readiness models: a systematic literature review of model dimensions. Information. 2020;11(7):1-13.

Rauch E, Vickery AR, Brown CA, Matt DT. SME requirements and guidelines for the design of smart and highly adaptable manufacturing systems. In: Matt D, Modrák V, Zsifkovits H, editors. Industry 4.0 for SMEs. Cham: Palgrave Macmillan; 2020. p. 39-72.

Baygin M, Yetis H, Karakose M, Akin E. An effect analysis of industry 4.0 to higher education. The 15th International Conference on Information Technology Based Higher Education and Training (ITHET); 2016 Sep 8-10; Istanbul, Türkiye. USA: IEEE; 2016. p. 1-4.

Thailand Development Research Institute (TDRI). Challenges of Thai workers in the digital age [Internet]. 2015 [cited 2020 Feb 27]. Available from: https://tdri.or.th/2015/01/thailaborinthedigitalage/. (In Thai)

Trstenjak M, Opetuk T. Industry 4.0 readiness factor calculation and process planning: state-of-the-art review. Trans Famena 2020;44:1-22.

Eastern Economic Corridor (EEC). Next-generation automotive [Internet]. 2019 [cited 2022 Apr 16]. Available from: https://www.eeco.or.th/th/next-generation-automotive-industry. (In Thai)

Thailand’s automotive industry. Opportunities and incentives ASEAN briefing [Internet]. 2018 [cited 2021 May 10]. Available from: https://www.aseanbriefing.com/news/thailands-automotive-industry-opportunities-incentives/.

Thailand Automotive Institute. GWM officially opened the 2nd fully operational factory outside China in Thailand [Internet]. 2022 [cited 2022 Jan 10]. Available from: https://www.thaiauto.or.th/2020/news/?news_subtype=automotive_industry_news.

Department of Business Development (DBD). Thailand standard industrial classification (TSIC) [Internet]. 2019 [cited 2019 Feb 27]. Available from: https://www.dbd.go.th/download/PDF_/book_business_man.pdf. (In Thai)

Thammasat University Research and Consultancy Institute (TURCI). Thailand's MICE industry report robotics [Internet]. 2018 [cited 2020 Aug 26]. Available from: https://elibrary.tceb.or.th/BookList/TCEB-Project-study/MICE-Industry-Reports/MICE-Industry-Report-2018-Robotics.aspx.

Thailand Development Research Institute (TDRI). TDRI offers 4 built to fulfill the potential of Thai students [Internet]. 2013 [cited 2020 Feb 27]. Available from: https://tdri.or.th/2014/05/yearend2013-human-capital-development/. (In Thai)

Summary the Twelfth National Economic and Social Development Plan (2017-2021) [Internet]. 2017 [cited 2020 Feb 27]. Available from: https://www.nesdc.go.th/ewt_dl_link.php?nid=9640.

The Institute of Industrial and Systems Engineers (IISE). Industrial and systems engineering BoK [Internet]. 2021 [cited 2021 Apr 16]. Available from: https://iise.org/Details.aspx?id=43631.

Mingaleva ZA, Vukovic NA. Development of engineering students competencies based on cognitive technologies in conditions of Industry 4.0. Int J Cogn Res Sci Eng Educ. 2020;8:93-101.

Gonçalves MJA, Rocha Á, Cota MP, Pimenta P. Model for identifying competencies and learning outcomes (MICRA). In: Pinheiro MM, Simões D, editors. Handbook of Research on Engaging Digital Natives in Higher Education Settings. USA: IGI Global; 2016. p. 154-70.

Bloom BS, Engelhart MD, Furst, EJ, Hill WH, Krathwohl DR. The taxonomy of educational objectives. Handbook 1, cognitive domain. New York: David McKay Company; 1956.

Simpson EJ. The classification of educational objectives in the psychomotor domain. Washington: Gryphon House; 1972. p. 1-35.

Pattanapairoj S, Nitisiri K, Sethanan K. A gap study between employers’ expectations in Thailand and current competence of master’s degree students in industrial engineering under Industry 4.0. Prod Eng Arch. 2021;27(1):50-7.

de Souza RG, Quelhas OLG. Model proposal for diagnosis and integration of Industry 4.0 concepts in production engineering courses. Sustainability. 2020;12(8):3471.

Pinzone M, Fantini P, Perini S, Garavaglia S, Taisch M, Miragliotta G. Jobs and skills in Industry 4.0: an exploratory research. In: Lödding H, Riedel R, Thoben KD, von Cieminski G, Kiritsis D, editors. Advances in Production Management Systems. The Path to Intelligent, Collaborative and Sustainable Manufacturing. APM 2017. IFIP Advances in Information and Communication Technology. Cham: Springer; 2017. p. 282-8.

Tan HS, Ivander, Oktarina R, Reynaldo V, Sharina C. Conceptual development of learning factory for industrial engineering education in Indonesia context as an enabler of students’ competencies in Industry 4.0 era. IOP Conf Ser: Earth Environ Sci. 2020;426:012123.

Ahadov A, Asgarov ES, El-Thalji I. A summary of adapting Industry 4.0 vision into engineering education in Azerbaijan. IOP Conf Ser: Mater Sci Eng. 2019;700:012063.

Sackey SM, Bester A, Adams D. Industry 4.0 learning factory didactic design parameters for industrial engineering education in South Africa. S Afr J Ind Eng. 2017;28(1):114-24.

Ratnasingam J, Yi LY, Abdul Azim A, Halis R, Choon Liat L, Khoo A, et al. Assessing the awareness and readiness of the Malaysian furniture industry for Industry 4.0. BioRes. 2020;15(3):4866-85.

Bischof-dos-Santos C, de Oliveira E. Production engineering competencies in the Industry 4.0 context: perspectives on the Brazilian labor market. Production. 2020;30:1-10.

Sánchez Carracedo F, Soler A, Martín C, López D, Ageno A, Cabré J, et al. Competency maps: an effective model to integrate professional competencies across a STEM curriculum. J Sci Educ Technol. 2018;27(5):448-68.

Employment and Training Administration (ETA). Engineering competency model clearing house employment and training administration [Internet]. 2020 [cited 2020 Dec 17]. Available from: https://www.careeronestop.org/competencymodel/ competency-models/engineering.aspx.

Kuzminov Y, Sorokin P, Froumin ID. Generic and specific skills as components of human capital: new challenges for education theory and practice. Foresight STI Gov. 2019;13(2):19-41.

Brito CR, Ciampi MM, Vasconcelos RM, Amaral LA, Santos HD, Barros VA. Rethinking engineering education. 2017 IEEE Frontiers in Education Conference (FIE); 2017 Oct 18-21; Indianapolis, USA. USA: IEEE; 2017. p. 1-5.

Backa L, Wihersaari M. Future engineering education: what competences are energy companies looking for when recruiting graduates with a master of science (technology) degree?. Eng Educ. 2014;991):2-17.

Lönngren J. Wicked problems in engineering education: preparing future engineers to work for sustainability. Environ Educ Res. 2019;25(12):1808-9.

Rajala SA. Beyond 2020: preparing engineers for the future. Proc IEEE. 2012;100(Special Centennial Issue):1376-83.

Mourtzis D. Development of skills and competences in manufacturing towards education 4.0: a teaching factory approach. In: Ni J, Majstorovic V, Djurdjanovic D, editors. Proceedings of the 3rd International Conference on the Industry 4.0 Model for Advanced Manufacturing (AMP 2018). Lecture Notes in Mechanical Engineering. Cham: Springer; 2018. p. 194-210.

Terkowsky C, Frye S, May D. Online engineering education for manufacturing technology: Is a remote experiment a suitable tool to teach competences for “Working 4.0”?. Eur J Educ. 2019;54(4):577-90.

Monteiro F, Leite C, Rocha C. From the dominant engineering education perspective to the aim of promoting service to humanity and the common good: the importance of rethinking engineering education. Eur J Eng Educ. 2019;44(4):504-18.

Bussey M, Song MM, Hsieh SH. Anticipatory imagination as a tool for rethinking engineering education. J Prof Iss Eng Ed Pr. 2017;143(4):1-5.

Fabregat J. Explicit training in human values and social attitudes of future engineers in Spain: commentary on "preparing to understand and use science in the real world: interdisciplinary study concentrations at the technical University of Darmstadt". Sci Eng Ethics. 2013;19(4):1551-6.

Lönngren J. Exploring the discursive construction of ethics in an introductory engineering course. J Eng Educ. 2021;110(10:44-69.

Jerman A, Pejić Bach M, Bertoncelj A. A bibliometric and topic analysis on future competences at smart factories. Machines. 2018;6(3):1-13.

Liszka K, Klimkiewicz K, Malinowski P. Polish foundry engineer with regard to changes carried by the industry 4.0. Arch Foundry Eng. 2019;19(1):103-8.

Muñoz-La Rivera F, Hermosilla P, Delgadillo J, Echeverría D. The sustainable development goals (SDGs) as a basis for innovation skills for engineers in the Industry 4.0 context. Sustainability. 2020;12(16):1-14.

Lantada AD. Engineering education 5.0: continuously evolving engineering education. Int J Eng Educ. 2020;36(6):1814-32.

Soboleva EV, Karavaev NL. Preparing engineers of the future: the development of environmental thinking as a universal competency in teaching robotics. Eur J Contemp Educ. 2020;9(1):160-76.

King I, Saxena C, Pak C, Lam CM, Cai H. Rethinking engineering education: policy, pedagogy, and assessment during crises. IEEE Signal Process Mag. 2021;38(3):174-84.

Segalàs J, Ferrer-Balas D, Svanström M, Lundqvist U, Mulder KF. What has to be learnt for sustainability? a comparison of bachelor engineering education competences at three European universities. Sustain Sci. 2009;4:17-27.

Hahn L, Sorenson L. Developing engineering students’ language and cultural skills for academic and professional success. 2014 IEEE Frontiers in Education Conference (FIE); 2014 Oct 22-25; Madrid, Spain. USA: IEEE; 2014. p. 1-4.

Render DN, Holgate HA, Calahan CA. Facilitating intercultural development: Preparing future engineers for multidisciplinary teams and multicultural environments. 2018 IEEE Frontiers in Education Conference (FIE); 2018 Oct 3-6; San Jose, USA. USA: IEEE; 2018. p. 1-9.

Stefanovic M. The objectives, architectures and effects of distance learning laboratories for industrial engineering education. Comput Educ. 2013;69:250-62.

Behl DV, Ferreira S. Systems thinking: an analysis of key factors and relationships. Procedia Comput Sci. 2004;36:104-9.

Herkert JR. Moral dilemmas in engineering. In: Herkert JR, editor. Social, ethical, and policy implications of engineering. Hoboken: Wiley-IEEE Press; 1999. p. 77-80.

van Laar E, van Deursen AJAM, van Dijk JAGM, de Haan J. 21st-century digital skills instrument aimed at working professionals: Conceptual development and empirical validation. Telemat Inform. 2018;35(8):2184-200.

Xiao J, Sun‐Lin HZ, Lin TH, Li M, Pan Z, Cheng HC. What makes learners a good fit for hybrid learning? learning competences as predictors of experience and satisfaction in hybrid learning space. Br. J Educ Technol. 2020;51(4):1203-19.

Wrobel-Lachowska M, Wisniewski Z, Polak-Sopinska A, Lachowski R. ICT in logistics as a challenge for mature workers: knowledge management role in information society. In: Goossens R, editor. Advances in Social & Occupational Ergonomics. AHFE 2017. Advances in Intelligent Systems and Computing. Cham: Springer; 2018. p. 171-8.

Ferris TLJ, Aziz M. A psychomotor skills extension to Bloom’s taxonomy of education objectives for engineering education. Exploring Innovation in Education and Research (iCEER-2005); 2005 Mar 1-5; Tainan, Taiwan. p. 1-6.

Wichajaroen W, Chompu-inwai R. Assessment of phase of Industry 4.0 adoption: a pilot study in automotive industry in Thailand. Eng J CMU. 2022;29(2):1-14.

Ismail FKM, Zubairi AMB. Item objective congruence analysis for multidimensional items content validation of a reading test in Sri Lankan university. English Lang Teach. 2022;15(1):106-17.

Brown JD. Testing in language programs: a comprehensive guide to English language assessment. Hawaii: McGraw-Hill; 2005.

Yongpisanphob W. Industry outlook 2019-2021: auto parts industry [Internet]. 2019 [updated 2019 Aug 16; cited 2023 Dec 10]. Available from: https://www.krungsri.com/en/research/industry/industry-outlook/hi-tech-industries/auto-parts/io/auto-parts-19.

Yongpisanphob W. Industry outlook 2020-2022: auto parts industry [Internet]. 2020 [updated 2020 Sep 10; cited 2023 Dec 10]. Available from: https://www.krungsri.com/en/research/industry/industry-outlook/hi-tech-industries/auto-parts/io/auto-parts-2021.

Yongpisanphob W. Industry outlook 2023-2025: auto parts industry [Internet]. 2023 [updated 2023 Mar 1; cited 2023 Dec 10]. Available from: https://www.krungsri.com/en/research/industry/industry-outlook/hi-tech-industries/auto-parts/io/auto-parts-2023-2025.