Accurate ultimate tensile strength classification in friction stir welding of symmetric AA5052 weld seams using ensemble deep learning model

Main Article Content

Abstract

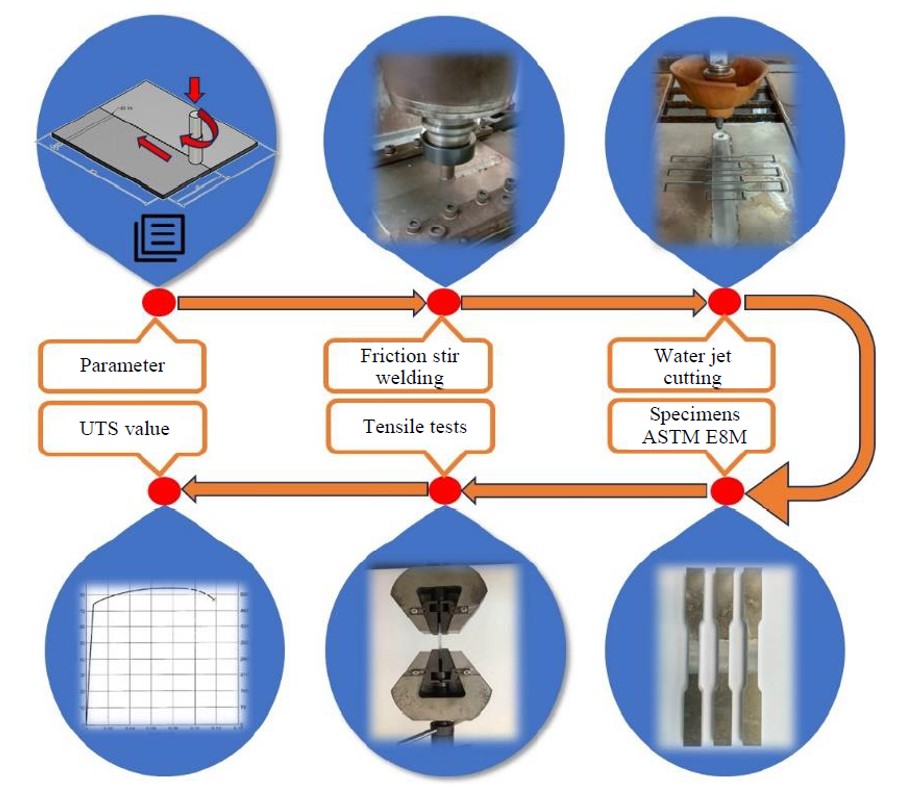

This research introduces a comprehensive classification and analysis system tailored for accurately determining the ultimate tensile strength (UTS) of weld seams. Traditional UTS assessment methods typically depend on destructive testing, which tends to be both lengthy and expensive, limiting their continuous application in quality control of welding procedures. This study leverages deep learning techniques, segmenting the dataset into subsets for training and validation in both multi-class and binary classification scenarios. The model devised in this study incorporates cutting-edge methodologies including geometric enhancement, U-Net based image segmentation, an image augmentation of diverse deep learning models, and decision fusion tactics. A significant aspect of this research was the success of Experiment 33, which skillfully combined various methodologies, resulting in outstanding performance. This experiment demonstrated exceptional accuracy in multiclass classification, alongside impressive outcomes in binary classification, achieving a high accuracy rate of 97.4% and an F1 score of 96.5%. This level of accuracy is indicative of the average performance across all models that incorporated the He-UWA for decision fusion strategy. It encompasses the efficacy of all models using He-UWA, with or without image segmentation. These findings underscore the effectiveness of our proposed model in accurately classifying UTS in friction stir welding. This represents a crucial advancement in assessing the quality of welding processes and provides a solid foundation for future investigations in this area.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

Ahmed MMZ, El-Sayed Seleman MM, Fydrych D, Çam G. Friction stir welding of aluminum in the aerospace industry: the current progress and state-of-the-art review. Materials. 2023;16(8):2971.

Shinde G, Gajghate S, Dabeer PS, Seemikeri CY. Low cost friction stir welding: a review. Mater Today Proc. 2017;4(8):8901-10.

Yang Y, Zhou L. Improving corrosion resistance of friction stir welding joint of 7075 aluminum alloy by micro-arc oxidation. J Mater Sci Technol. 2014;30(12):1251-4.

Sato YS, Sugiura Y, Shoji Y, Park SHC, Kokawa H, Ikeda K. Post-weld formability of friction stir welded Al alloy 5052. Mater Sci Eng A. 2004;369(1-2):138-43.

Matitopanum S, Pitakaso R, Sethanan K, Srichok T, Chokanat P. Prediction of the Ultimate Tensile Strength (UTS) of Asymmetric Friction Stir Welding Using Ensemble Machine Learning Methods. Processes. 2023;11(2):391.

Taye MM. Theoretical understanding of convolutional neural network: concepts, architectures, applications, future directions. Computation. 2023;11(3):52.

Alzubaidi L, Zhang J, Humaidi AJ, Al-Dujaili A, Duan Y, Al-Shamma O, et al. Review of deep learning: concepts, CNN architectures, challenges, applications, future directions. J Big Data. 2021;8:1-74.

Tripathy S, Singh R. Convolutional neural network: an overview and application in image classification. In: Poonia RC, Singh V, Singh Jat D, Diván MJ, Khan MS, editors. Proceedings of Third International Conference on Sustainable Computing. Advances in Intelligent Systems and Computing, vol 1404. Singapore: Springer; 2022. p. 145-53.

Chiaranai S, Pitakaso R, Sethanan K, Kosacka-Olejnik M, Srichok T, Chokanat P. Ensemble deep learning ultimate tensile strength classification model for weld seam of asymmetric friction stir welding. Processes. 2023;11(2):434.

Yang Y, Lv H, Chen N. A survey on ensemble learning under the era of deep learning. Artif Intell Rev. 2023;56(6):5545-89.

Zhou X, He J, Yang C. An ensemble learning method based on deep neural network and group decision making. Knowl.-Based Syst. 2022;239:107801.

Alomar K, Aysel HI, Cai X. Data augmentation in classification and segmentation: a survey and new strategies. J Imaging. 2023;9(2):46.

Negassi M, Wagner D, Reiterer A. Smart (sampling) augment: optimal and efficient data augmentation for semantic segmentation. Algorithms. 2022;15(5):165.

Lee J, Lim K, Cho J. Improved monitoring of wildlife invasion through data augmentation by extract–append of a segmented entity. Sensors. 2022;22(19):7383.

Chakraborty S, Saha AK, Ezugwu AE, Agushaka JO, Zitar RA, Abualigah L. Differential evolution and its applications in image processing problems: A comprehensive review. Arch Computat Methods Eng. 2023;30(2):985-1040.

Smith AG, Petersen J, Selvan R, Rasmussen CR. Segmentation of roots in soil with U-Net. Plant Methods. 2020;16(1):1-15.

Mishra RS, Ma ZY. Friction stir welding and processing. Mater Sci Eng R Rep. 2005;50(1-2):1-78. 2005.

Lombard H, Hattingh DG, Steuwer A, James MN. Optimising FSW process parameters to minimise defects and maximise fatigue life in 5083-H321 aluminium alloy. Eng Fract Mech. 2008;75(3-4):341-54.

Khalafe WH, Sheng EL, Bin Isa MR, Omran AB, Shamsudin SB. The effect of friction stir welding parameters on the weldability of aluminum alloys with similar and dissimilar metals. Metals. 2022;12(12):2099.

Liu G, Murr LE, Niou CS, McClure JC, Vega FR. Microstructural aspects of the friction-stir welding of 6061-T6 aluminum. Scripta materialia. 1997;37(3):355-61.

Wang H, Lei Z, Zhang X, Zhou B, Peng J. A review of deep learning for renewable energy forecasting. Energy Convers Manag. 2019;198:111799.

Yao Q, Wang M, Chen Y, Dai W, Li YF, Tu WW, et al. Taking human out of learning applications: a survey on automated machine learning. arXiv preprint arXiv:181013306. 2018:1-20.

He K, Zhang X, Ren S, Sun J. Deep residual learning for image recognition. IEEE Conference on Computer Vision and Pattern Recognition (CVPR); 2016 Jun 27-30; Las Vegas, USA. USA: IEEE; 2016. p. 770-8.

Ioffe S, Szegedy C. Batch normalization: accelerating deep network training by reducing internal covariate shift. Proceedings of the 32nd International Conference on Machine Learning; 2015 Jul 6-11; Lille, France. p. 1-9.

Aggarwal M, Khullar V, Goyal N, Singh A, Tolba A, Thompson EB, et al. Pre-Trained deep neural network-based features selection supported machine learning for rice leaf disease classification. Agriculture. 2023;13(5):936.

Maddury S, Desai K. Using deep learning to determine amyloid deposition through pet and clinical data for Alzheimer's prognosis. medRxiv. 2022:1-12.

Ma N, Zhang X, Zheng HT, Sun J. Shufflenet v2: practical guidelines for efficient cnn architecture design. In: Ferrari V, Hebert M, Sminchisescu C, Weiss Y, editors. Computer Vision – ECCV 2018. Lecture Notes in Computer Science, vol 11218. Cham: Springer; 2018. p. 122-38.

Li G, Wu Y, Hao X. Smaller and more efficient image classification neural network for mobile devices. Research Square. 2022:1-18.

Iandola FN, Han S, Moskewicz MW, Ashraf K, Dally WJ, Keutzer K. SqueezeNet: AlexNet-level accuracy with 50x fewer parameters and< 0.5 MB model size. arXiv:160207360. 2016:1-13.

Zhu J, Zhang C, Zhang C. Papaver somniferum and Papaver Rhoeas classification based on visible capsule images using a modified MobileNetV3-Small network with transfer learning. Entropy. 2023;25(3):447.

Mohammed A, Kora R. A comprehensive review on ensemble deep learning: opportunities and challenges. J King Saud Univ - Comput Inf Sci. 2023;35(2):757-74.

Jabbar MA. Breast cancer data classification using ensemble machine learning. Eng Appl Sci Res. 2021;48(1):65-72.

Alsulami AA, AL-Ghamdi ASAM, Ragab M. Enhancement of E-learning student’s performance based on ensemble techniques. Electronics. 2023;12(6):1508.

Khoder A, Dornaika F. Ensemble learning via feature selection and multiple transformed subsets: application to image classification. Appl Soft Comput. 2021;113:108006.

Xu H, Yan ZH, Ji BW, Huang PF, Cheng JP, Wu XD. Defect detection in welding radiographic images based on semantic segmentation methods. Measurement. 2022;188:110569.

Zhang Y, You D, Gao X, Zhang N, Gao PP. Welding defects detection based on deep learning with multiple optical sensors during disk laser welding of thick plates. J Manuf Syst. 2019;51:87-94.