A comparative study of jarosite and other cementitious materials as a concrete material – A review

Main Article Content

Abstract

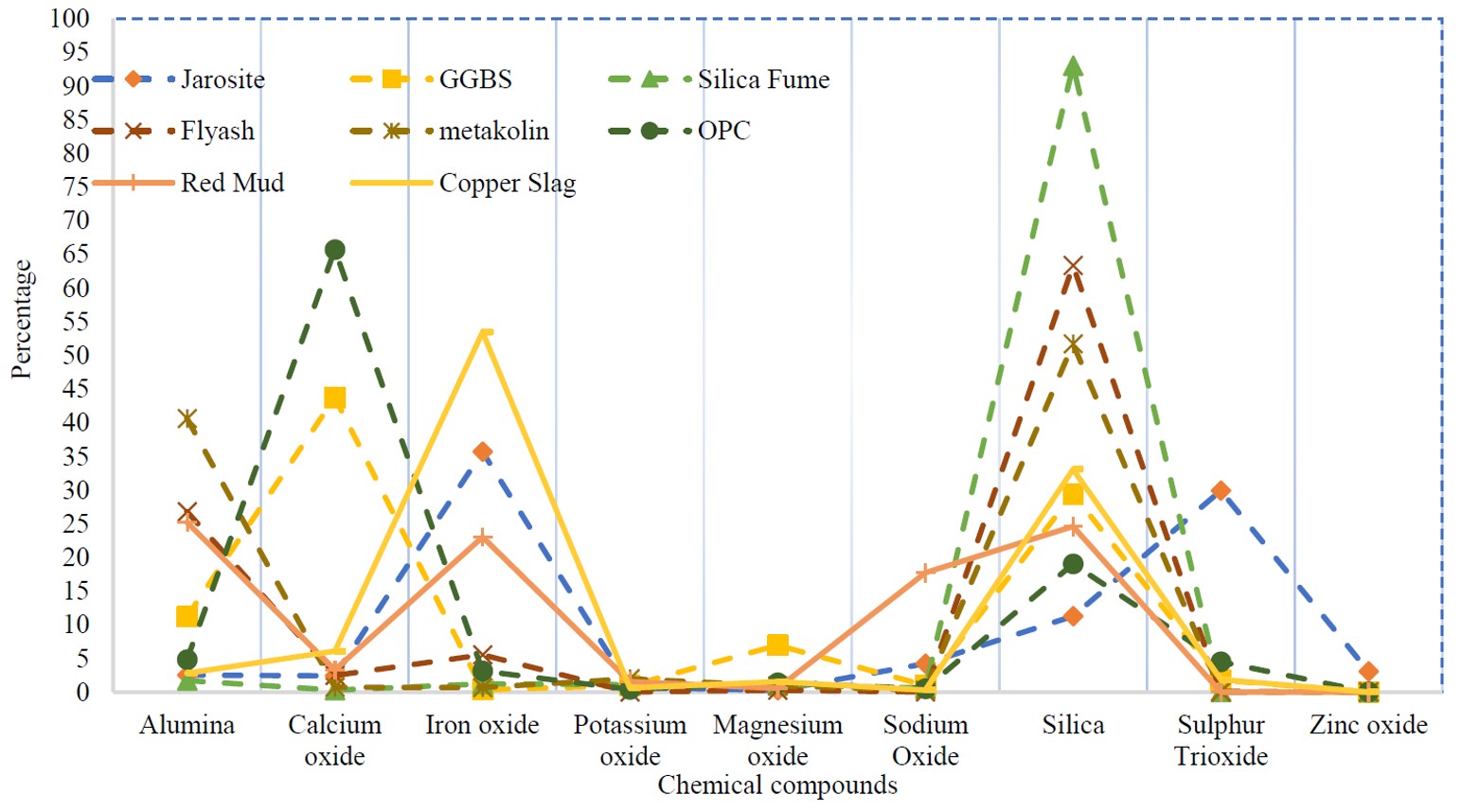

In recent years, zinc production has grown exponentially, compensating for the need arising from worldwide industrial growth. Jarosite is a non-biodegradable mineral residue obtained from smelting zinc ore. Jarosite is categorised as a hazardous material due to its high metal ion concentration, and hence, the safe disposal of massive volumes of jarosite waste poses a significant burden. This review article highlights how various proportions of jarosite affect concrete's fresh, mechanical, hydration, microstructural, and durability properties. When used in specific volumes, jarosite positively impacts the concrete compressive strength. The hydration mechanism of jarosite-incorporated concrete justifies forming a secondary hydration reaction, which causes dense morphology observed during microstructure analysis. Further, when jarosite is incorporated into concrete, the leaching characteristics of raw jarosite are observed to be substantially reduced and meet the safe limits. Based on the observations, a jarosite replacement level of 15% to the cementitious mix shows improvement in the mechanical and durability properties of the concrete. These findings could be used to identify a sustainable approach to reutilise the zinc industry waste by-products (jarosite). The experimental values of jarosite-incorporated concrete were compared with those of similar well-researched industrial waste materials such as red mud and copper slag to ensure that the observation and evaluation are accurate and trustworthy.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

Pappu A, Saxena M, Asolekar SR. Jarosite characteristics and its utilisation potentials. Sci Total Environ. 2006;359(1-3):232-43.

Montanaro L, Bianchini N, Rincon JM, Romero M. Sintering behaviour of pressed red mud wastes from zinc hydrometallurgy. Ceram Int. 2001;27(1):29-37.

Calla-Choque D, Nava-Alonso F, Fuentes-Aceituno JC. Acid decomposition and thiourea leaching of silver from hazardous jarosite residues: effect of some cations on the stability of the thiourea system. J Hazard Mater. 2016;317:440-8.

Gupta C, Prasad A. Strength and durability of lime-treated jarosite waste exposed to freeze and thaw. J Cold Reg Eng. 2018;32(1): 1-11.

Gupta C, Prasad A. A parametric strength study of jarosite waste. Proc Inst Civ Eng Waste Resour Manag. 2018;170(3-4):149-61.

Sinha AK, Havanagi VG, Shahu JT. Stabilised jarofix waste material for road construction. Int J Pavement Eng. 2021;22(7):882-93.

Kangas P, Koukkari P, Wilson B, Lundström M, Rastas JK, Saikkonen PJ, et al. Hydrometallurgical processing of jarosite to value-added products. Conference in Minerals Engineering 2017; 2017 Feb 7-8; Luleå, Sweden.

Tolcin A. Zinc production 2023 [Internet]. USA: U.S. Geological Survey; 2023 [cited 2023 Sep 5]. Available from: https://www.usgs.gov/centers/national-minerals-information-center/zinc-statistics-and-information.

Kerolli-Mustafa M, Ćurković L, Fajković H, Rončević S. Ecological risk assessment of jarosite waste disposal. Croat Chem Acta. 2015;88(2):189-96.

Ju S, Zhang Y, Zhang Y, Xue P, Wang Y. Clean hydrometallurgical route to recover zinc, silver, lead, copper, cadmium and iron from hazardous jarosite residues produced during zinc hydrometallurgy. J Hazard Mater. 2011;192(2):554-8.

Qureshi HJ, Ahmad J, Majdi A, Saleem MU, Al Fuhaid AF, Arifuzzaman M. A study on sustainable concrete with partial substitution of cement with red mud: a review. Materials. 2022;15(21):7761.

Vembu PRS, Ammasi AK. Eco-efficiency evaluation of sustainable self-compacting concrete using magnesite mine waste. Case Stud Constr Mater. 2024;20:e02765.

Mirhosseini SR, Fadaee M, Tabatabaei R, Fadaee MJ. Mechanical properties of concrete with Sarcheshmeh mineral complex copper slag as a part of cementitious materials. Constr Build Mater. 2017;134 44-9.

Shunmuga Vembu PR, Ammasi AK. A comprehensive review on the factors affecting bond strength in concrete. Buildings. 2023;13(3):577.

Shunmuga Vembu PR, Ammasi AK. Strength and durability of dry sewage sludge (DSS) as a replacement for fine aggregates. Mater Today Proc. 2022;61:232-6.

Costa FN, Ribeiro DV. Reduction in CO2 emissions during production of cement, with partial replacement of traditional raw materials by civil construction waste (CCW). J Clean Prod. 2020;276:123302.

Radonjanin V, Malešev M, Marinković S, Al Malty AES. Green recycled aggregate concrete. Constr Build Mater. 2013;47:1503-11.

Arunkumar K, Muthukannan M, Kumar AS, Ganesh AC, Devi RK. Hybrid fibre reinforced eco-friendly geopolymer concrete made with waste wood ash: a mechanical characterization study. Eng Appl Sci Res. 2022;49(2):235-47.

Ridtirud C, Posi P, Chindaprasirt P. Development of high performance concrete containing high calcium fly ash. KKU Eng J. 2016;43(S3):446-50.

Vimonsatit V, Chindaprasirt P, Ruangsiriyakul S, Sata V. Influence of fly ash fineness on water requirement and shrinkage of blended cement mortars. KKU Eng J. 2015;42(4):311-6.

Phoo-ngernkham T, Sinsiri T. Workability and compressive strength of geopolymer mortar from fly ash containing diatomite. KKU Eng J. 2011;38(1):11-26.

Becerra-Duitama JA, Rojas-Avellaneda D. Pozzolans: a review. Eng Appl Sci Res. 2022;49(4):495-504.

Yamgar SB, Takkalaki SR. Study and analysis of strength of GGBS concrete. Int J Eng Manag Res. 2018;8(6):28-47.

Jithendra C, Elavenil S. Influences of parameters on slump flow and compressive strength properties of aluminosilicate based flowable geopolymer concrete using taguchi method. Silicon 2020;12:595-602.

Jithendra C, Elavenil S. Role of superplasticizer on GGBS based geopolymer concrete under ambient curing. Mater Today Proc. 2019;18:148-54.

Nagajothi S, Elavenil S, Angalaeswari S, Natrayan L, Mammo WD. Durability studies on fly ash based geopolymer concrete incorporated with slag and alkali solutions. Adv Civ Eng. 2022;2022:7196446.

Nagajothi S, Elavenil S. Effect of GGBS addition on reactivity and microstructure properties of ambient cured fly ash based geopolymer concrete. Silicon. 2021;13:507-16.

Nikbin IM, Aliaghazadeh M, Charkhtab S, Fathollahpour A. Environmental impacts and mechanical properties of lightweight concrete containing bauxite residue (red mud). J Clean Prod. 2018;172:2683-94.

Varun BK, Harish BA, Bharatharaj Etigi YB, Kiran Kumar HS, Hanumesh BM. Effect of red mud and silica fume on cement. Int J Res Appl Sci Eng Technol. 2018;6(XII):522-8.

Siddique R, Singh M, Jain M. Recycling copper slag in steel fibre concrete for sustainable construction. J Clean Prod. 2020;271:122559.

Liu J, Guo R. Applications of steel slag powder and steel slag aggregate in ultra-high performance concrete. Adv Civ Eng. 2018;2018:1426037.

Ghorbani S, Sun Y, Mohan MK, Matthys S. Effect of copper and stainless steel slags on fresh, mechanical and pore structure properties of alkali activated ground granulated blast furnace slag. Case Stud Constr Mater. 2023;18:e01981.

Kirthiga R, Elavenil S. Potential utilization of sugarcane bagasse ash in cementitious composites for developing inorganic binder. Ain Shams Eng J. 2023;14(11):102560.

Kirthiga R, Elavenil S. A review on using inorganic binders in fiber reinforced polymer at different conditions to strengthen reinforced concrete beams. Constr Build Mater. 2022;352:129054.

Kumar S, Gupta RC, Thomas BS, Mehra P. Aggregate replacement and its usefulness in cement concrete for sustainable development—a study on rubber, Jarosite and sandstone aggregates. In: Charytonowicz J, editor. Advances in Human Factors and Sustainable Infrastructure. Advances in Intelligent Systems and Computing, vol 493. Cham: Springer; 2016. p. 13-25.

Mehra P, Gupta RC, Thomas BS. Properties of concrete containing jarosite as a partial substitute for fine aggregate. J Clean Prod. 2016;120:241-8.

Mehra P, Gupta RC, Thomas BS. Assessment of durability characteristics of cement concrete containing jarosite. J Clean Prod. 2016;119:59-65.

Mehra P, Kumar S, Thomas BS, Gupta RC. Analysis on the hazardous jarosite added concrete. Constr Build Mater. 2018;191: 253-9.

Gared O, Gaur A. Feasibility study of jarosite as cement replacement in rigid pavement. Mater Today Proc. 2021;44:4337-41.

Ray S, Daudi L, Yadav H, Ransinchung GD. Utilization of jarosite waste for the development of sustainable concrete by reducing the cement content. J Clean Prod. 2020;272:122546.

Saini SK, Ransinchung RN GD, Kumar P. Effect of different mineral admixtures on the performance of pavement quality concrete containing the optimum amount of jarosite as partial replacement of cement. Arab J Sci Eng. 2022;47:13523-35.

Saini SK, Ransinchung GD, Kumar P, Ray S. Investigation of jarosite-cement blends for hydration process and mechanical behavior in PQC mixes. Innov Infrastruct Solut. 2022;7:198.

Gupta T, Sachdeva SN. Investigations on jarosite mixed cement concrete pavements. Arab J Sci Eng. 2019;44:8787-97.

Gupta T, Sachdeva SN. Study of mechanical, micro-structural and environmental properties of concrete containing zinc industry waste for pavements. Constr Build Mater. 2020;245:118331.

Gupta T, Sachdeva SN. Prediction of compressive and flexural strengths of jarosite mixed cement concrete pavements using artificial neural networks. Road Mater Pavement Des. 2021;22(7):1521-42.

Debbarma S, Ransinchung G, Singh S. Zinc waste as a substitute for Portland cement in roller-compacted concrete pavement mixes containing RAP aggregates. J Mater Civ Eng. 2020;32(8):1-12.

Mymrin V, Vazquez Vaamonde A. New construction materials from Spanish jarosite processing wastes. Miner Eng. 1999;12(11):1399-402.

Asokan P, Saxena M, Asolekar SR. Hazardous jarosite use in developing non-hazardous product for engineering application. J Hazard Mater. 2006;137(3):1589-99.

Katsioti M, Boura P, Agatzini S, Tsakiridis PE, Oustadakis P. Use of jarosite/alunite precipitate as a substitute for gypsum in Portland cement. Cem Concr Compos. 2005;27(1):3-9.

Gupta T, Sachdeva SN. Utilisation of jarosite in cement concrete – a review. Int J Environ Waste Manag. 2020;26(4):504-19.

Bergé JS. Full movement beyond control and environmental governance: taking silent risk seriously. USA: SSRN; 2018.

Arslan C, Arslan F. Thermochemical review of jarosite and goethite stability regions at 25 and 95°C. Turkish J Eng Environ Sci. 2003;27:45-52.

Sinha AK, Havanagi VG, Arora VK, Ranjan A, Mathur S. Recycling Jarofix waste as a construction material for embankment and sub grade. J Solid Waste Technol Manag. 2012;3:169-81.

Seyer S, Chen T, Dutrizac J. Jarofix: addressing iron disposal in the zinc industry. JOM. 2001;53:32-5.

Arroyo M, Nova R, Tsige M. Microstructure and compactive instabilities of a stabilized residue. J Mater Civ Eng. 2006;18(2):272-82.

Swayze GA, Desborough GA, Smith KS, Lowers HA, Hammarstrom JM, Diehl SF, et al. Chapter B: Understanding Jarosite—From Mine Waste to Mars. In: Verplanck PL, editor. Understanding Contaminants Associated with Mineral Deposits. Reston: U.S. Geological Survey; 2008. p. 8-13.

Gupta C, Prasad A. Variables controlling strength of lime stabilized jarosite waste. Int J Geo-Engineering. 2018;9:6.

Gupta C, Prasad A. The influence of ground-granulated blast-furnace slag on geotechnical properties of jarosite waste. In: Kalamdhad A, editor. Recent Developments in Waste Management. Lecture Notes in Civil Engineering, vol 57. Singapore: Springer; 2020. p. 179-94.

ASTM. D 2487-06: Standard practice for classification of soils for engineering purposes (unified soil classification system). West Conshohocken: ASTM International; 2006.

Satyanarayana Reddy CNV, Sanghamitra B, Vinathi Angel R. A study on properties of jerosite waste for landfill capping design. Proceedings of Indian Geotechnical Conference; 2011 Dec 15-17; Kochi, India. p. 755-8.

Liu Z, Takasu K, Koyamada H, Suyama H. A study on engineering properties and environmental impact of sustainable concrete with fly ash or GGBS. Constr Build Mater. 2022;316:125776.

Choo H, Lim S, Lee W, Lee C. Compressive strength of one-part alkali activated fly ash using red mud as alkali supplier. Constr Build Mater. 2016;125:21-8.

Borosnyói A. Long term durability performance and mechanical properties of high performance concretes with combined use of supplementary cementing materials. Constr Build Mater. 2016;112:307-24.

Shijagurumayum C, Singh NS, Thokchom S. Fibre reinforced alkali activated composites exposed to elevated temperature. Eng Appl Sci Res. 2022;49(4):593-602.

Heng K, Areemit N, Chindaprasirt P. Behavior of concrete cylinders confined by a ferro-geopolymer jacket in axial compression. Eng Appl Sci Res. 2017;44(2):90-6.

Nagajothi S, Elavenil S. Strength assessment of geopolymer concrete using M-sand. Int J Chem Sci. 2016;14:115-26.

Kang SP, Kwon SJ. Effects of red mud and alkali-activated slag cement on efflorescence in cement mortar. Constr Build Mater. 2017;133:459-67.

Bayat A, Hassani A, Yousefi AA. Effects of red mud on the properties of fresh and hardened alkali-activated slag paste and mortar. Constr Build Mater. 2018;167:775-90.

Hyeok-Jung K, Kang SP, Choe GC. Effect of red mud content on strength and efflorescence in pavement using alkali-activated slag cement. Int J Concr Struct Mater. 2018;12:18.

Zhou W, Shi X, Lu X, Qi C, Luan B, Liu F. The mechanical and microstructural properties of refuse mudstone-GGBS-red mud based geopolymer composites made with sand. Constr Build Mater. 2020;253:119193.

Chen X, Guo Y, Ding S, Zhang H, Xia F, Wang J, et al. Utilization of red mud in geopolymer-based pervious concrete with function of adsorption of heavy metal ions. J Clean Prod. 2019;207:789-800.

Lemougna PN, Wang KT, Tang Q, Cui XM. Study on the development of inorganic polymers from red mud and slag system: application in mortar and lightweight materials. Constr Build Mater. 2017;156:486-95.

Joshaghani A, Moeini MA, Balapour M, Moazenian A. Effects of supplementary cementitious materials on mechanical and durability properties of high-performance non-shrinking grout (HPNSG). J Sustain Cem Based Mater. 2018;7(1):38-56.

Zhang X, Du X, Zhao X, Zhang R, Hou P, Zhou Z, et al. The synergistic effect of nano-SiO2 with silica fume in cement-based material. J Sustain Cem Based Mater. 2017;6(4):267-79.

Xu W, Yang H, Mao Q, Luo L, Deng Y. Removal of Heavy metals from acid mine drainage by red mud–based geopolymer pervious concrete: batch and long–term column studies. Polymers. 2022;14(24):5355.

de Oliveira DRC, Rossi CRC. Concretes with red mud coarse aggregates. Mater Res. 2012;15(3):333-40.

Chen W, Li J. Effects of different silicon sources on the properties of geopolymer planting concrete mixed with red mud. Sustainability. 2023;15(5):4427.

Arunachelam N, Maheswaran J, Chellapandian M, Ozbakkaloglu T. Effective utilization of copper slag for the production of geopolymer concrete with different NaOH molarity under ambient curing conditions. Sustainability. 2022;14(23):16300.

Zhang L, Gong H, Liu J, Li H. Mechanical properties and chloride penetration resistance of copper slag aggregate concrete. Fractal Fract. 2022;6(8):427.

Al-Jabri KS, Al-Saidy AH, Taha R. Effect of copper slag as a fine aggregate on the properties of cement mortars and concrete. Constr Build Mater. 2011;25(2):933-8.

Chen X, Zhou MK, Cong PL, Li X. Influence of SO3 content on the strength of cement-fly ash stabilized crushed-stones. In: Li G, Chen Y, Tang X, editors. Geosynthetics in Civil and Environmental Engineering. Berlin: Springer; 2008. p. 398-402.

Faraj RH, Sherwani AFH, Jafer LH, Ibrahim DF. Rheological behavior and fresh properties of self-compacting high strength concrete containing recycled PP particles with fly ash and silica fume blended. J Build Eng. 2021;34:101667.

Ding M, Schuiling RD, van der Sloot HA. Self-sealing isolation and immobilization: a geochemical approach to solve the environmental problem of waste acidic jarosite. Appl Geochem. 2002;17(2):93-103.

Wang YS, Peng KD, Alrefaei Y, Dai JG. The bond between geopolymer repair mortars and OPC concrete substrate: strength and microscopic interactions. Cem Concr Compos. 2021;119:103991.

Fallah-Valukolaee S, Mousavi R, Arjomandi A, Nematzadeh M, Kazemi M. A comparative study of mechanical properties and life cycle assessment of high-strength concrete containing silica fume and nanosilica as a partial cement replacement. Structures. 2022;46:838-51.

Aggelakopoulou E, Bakolas A, Moropoulou A. Properties of lime-metakolin mortars for the restoration of historic masonries. Appl Clay Sci. 2011;53(1):15-9.

Kanavaris F, Soutsos M, Chen JF. Enabling sustainable rapid construction with high volume GGBS concrete through elevated temperature curing and maturity testing. J Build Eng. 2023;63:105434.

Weeks C, Hand RJ, Sharp JH. Retardation of cement hydration caused by heavy metals present in ISF slag used as aggregate. Cem Concr Compos. 2008;30(10):970-8.

Shahi S, Fakhri E, Yavari H, Maleki Dizaj S, Salatin S, Khezri K. Portland cement: an overview as a root repair material. Biomed Res Int. 2022;2022:3314912.

Gandolfi MG, Van Landuyt K, Taddei P, Modena E, Van Meerbeek B, Prati C. Environmental scanning electron microscopy connected with energy dispersive x-ray analysis and Raman techniques to study proroot mineral trioxide aggregate and calcium silicate cements in wet conditions and in real time. J Endod. 2010;36(5):851-7.

Asokan P, Saxena M, Asolekar SR. Recycling hazardous jarosite waste using coal combustion residues. Mater Charact. 2010;61(12):1342-55.

Mehra P, Thomas BS, Kumar S, Gupta RC. Jarosite added concrete along with fly ash: properties and characteristics in fresh state. Perspect Sci. 2016;8:69-71.

Thomas J, Thaickavil NN, Abraham MP. Copper or ferrous slag as substitutes for fine aggregates in concrete. Adv Concr Constr. 2018;6(5):545-60.

Wang R, Shi Q, Li Y, Cao Z, Si Z. A critical review on the use of copper slag (CS) as a substitute constituent in concrete. Constr Build Mater. 2021;292:123371.

Venkatesh C, Nerella R, Chand MSR. Role of red mud as a cementing material in concrete : a comprehensive study on durability behavior. Innov Infrastruct Solut. 2021;6:13.

Barbhuiya SA, Basheer PAM, Clark MW, Rankin GIB. Effects of seawater-neutralised bauxite refinery residue on properties of concrete. Cem Concr Compos. 2011;33(6):668-79.

Venkatesh C, Ruben N, Chand MSR. Red mud as an additive in concrete : comprehensive characterization. J Korean Ceram Soc. 2020;57:281-9.

Song J, Feng S, Xiong R, Ouyang Y, Zeng Q, Zhu J, et al. Mechanical properties, pozzolanic activity and volume stability of copper slag- filled cementitious materials. Mater Sci. 2020;26(2):218-24.

Gopalakrishnan R, Nithiyanantham S. Microstructural, mechanical , and electrical properties of copper slag admixtured cement mortar. J Build Eng. 2020;31:101375.

Kaish ABMA, Odimegwu TC, Zakaria I, Abood MM. Effects of different industrial waste materials as partial replacement of fine aggregate on strength and microstructure properties of concrete. J Build Eng. 2021;35:102092.

dos Anjos MAG, Sales ATC, Andrade N. Blasted copper slag as fine aggregate in Portland cement concrete. J Environ Manage. 2017;196:607-13.

Jaturapitakkul C, Tangpagasit J, Songmue S, Kiattikomol K. Filler effect and pozzolanic reaction of ground palm oil fuel ash. Constr Build Mater. 2011;25(11):4287-93.

Tangpagasit J, Cheerarot R, Jaturapitakkul C, Kiattikomol K. Packing effect and pozzolanic reaction of fly ash in mortar. Cem Concr Res. 2005;35(6):1145-51.

Khan MNN, Jamil M, Karim MR, Zain MFM, Kaish ABMA. Filler effect of pozzolanic materials on the strength and microstructure development of mortar. KSCE J Civ Eng. 2017;21:274-84.

Guo Y, Xie J, Zheng W, Li J. Effects of steel slag as fine aggregate on static and impact behaviours of concrete. Constr Build Mater. 2018;192:194-201.

Xue G, Fu Q, Xu S, Li J. Macroscopic mechanical properties and microstructure characteristics of steel slag fine aggregate concrete. J Build Eng. 2022;56:104742.

Syam Sai P, Sukesh C. Strength properties of concrete by using red mud as a replacement of cement with hydrated lime. Int J Civ Eng Technol. 2017;8(3):38-49.

Viyasun K, Anuradha R, Thangapandi K, Santhosh Kumar D, Sivakrishna A, Gobinath R. Investigation on performance of red mud based concrete. Mater Today Proc. 2021;39:796-9.

Nandi S, Ransinchung G, Rana GB. A sustainable approach towards reducing cement consumption in the road sector using zinc industry waste. Int J Pavement Res Technol. 2022;15:1463-83.

Kunther W, Ferreiro S, Skibsted J. Influence of the Ca/Si ratio on the compressive strength of cementitious calcium-silicate-hydrate binders. J Mater Chem A. 2017;5:17401-12.

Shi C, Fernández-Jiménez A. Stabilization/solidification of hazardous and radioactive wastes with alkali-activated cements. J Hazard Mater. 2006;137(3):1656-63.