Development of a computational model for the estimation of biogas production from putrescible wastes

Main Article Content

Abstract

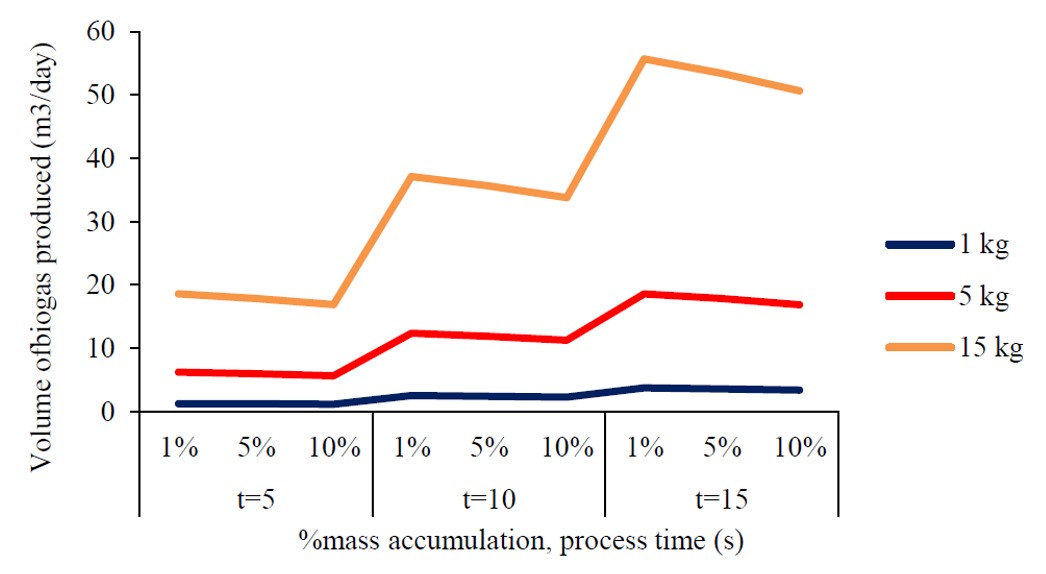

The use of putrescible wastes as a feed source for biogas production has been a research subject. The study aims to develop a simple computer model for estimating the volume of biogas produced from putrescible wastes. The predictive model was developed to predict the volume of biogas produced based on three parameters, the mass of waste used, the anaerobic processing time, and the percentage of residue accumulation in the reactor. The biogas estimator application was developed using the 2017 edition of Microsoft’s Visual Studio .Net software developer’s kit (SDK). The simple model does not require rigorous mathematical computations as the process parameters can readily be imputed in the simple data fields created. The model can operate in both batch and continuous modes. The result from both the batch and continuous biodegradation processes of 1.0 kg of putrescible waste per day in a biodigester using the Biogas Estimator model provided certain significant outputs. In the case of the batch process, a 1.0 kg mass of biodegradable putrescible waste yielded an average biogas production volume of about 0.236 m3 per day, while the resulting volume from the continuous process, 1.0 kg mass of biodegradable putrescible waste produced on average an estimated biogas volume of about 0.164 m3 per day. The values obtained are comparable to those of similar studies thereby validating the efficacy of the model. The model has been validated and is considered suitable for the estimation of biogas production from putrescible wastes.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

Alayi R, Shamel A, Kasaeian A, Harasii H, Topchlar MA. The role of biogas in sustainable development aspects of environmental, security, and economic. J Chem Pharm Res. 2016;8(4):112-8.

Hafeez S, Al-Salem SM, Manos G, Constantinou A. Fuel production using membrane reactors: a review. Environ Chem Lett. 2020;18:1477-90.

Wang B, Mi Z, Nistor I, Yuan XC. How does hydrogen-based renewable energy change with economic development? Empirical evidence from 32 countries. Int J Hydrog Energy. 2018;43(25):11629-38.

Fedailaine M, Moussi K, Khitous M, Abada S, Saber M, Tirichine N. Modeling of the anaerobic digestion of organic waste for biogas production. Procedia Comput Sci. 2015;52:730-7.

Aghbashlo M, Tabatabaei M, Hosseini SS, Dashti BB, Soufiyan MM. Performance assessment of a wind power plant using standard exergy and extended exergy accounting (EEA) approaches. J Clean Prod. 2018;171:127-36.

Anjum M, Khalid A, Mahmood T, Aziz I. Anaerobic co-digestion of catering waste with partially pretreated lignocellulosic crop residues. J Clean Prod. 2016;117:56-63.

Guenther-Lübbers W, Bergmann H, Theuvsen L. Potential analysis of the biogas production–as measured by effects of added value and employment. J Clean Prod. 2016;129:556-64.

Almasi F, Soltanian S, Hosseinpour S, Aghbashlo M, Tabatabaei M. Advanced soft computing techniques in biogas production technology. In: Tabatabaei M, Ghanavati H, editors. Biogas: Fundamentals, Process, and Operation, Vol 6. Cham: Springer; 2018. p. 387-417.

Holechek JL, Geli HME, Sawalhah MN, Valdez R. A global assessment: can renewable energy replace fossil fuels by 2050?. Sustainability. 2022;14(8):4792.

Fajobi MO, Lasode OA, Adeleke AA, Ikubanni PP, Balogun AO, Paramasivam P. Prediction of biogas yield from codigestion of lignocellulosic biomass using adaptive neuro-fuzzy inference system (ANFIS) Model. J Eng. 2023;2023:1-16.

Dahunsi SO. Mechanical pretreatment of lignocelluloses for enhanced biogas production: Methane yield prediction from biomass structural components. Bioresour Technol. 2019;280:18-26.

Dandikas V, Heuwinkel H, Lichti F, Drewes JE, Koch K. Correlation between biogas yield and chemical composition of grassland plant species. Energy Fuels. 2015;29(11):7221-9.

Hansen BD, Tamouk J, Tidmarsh CA, Johansen R, Moeslund TB, Jensen DG. Prediction of the methane production in biogas plants using a combined gompertz and machine learning model. In: Gervasi O, Murgante B, Misra S, Garau C, Blečić I, Taniar D, et al., editors. Computational Science and Its Applications–ICCSA 2020; 2020 Jul 1-4; Cagliari, Italy. Cham: Springer 2020. p. 734-45.

Appala VNSG, Pandhare NN, Bajpai S. Mathematical models for optimization of anaerobic digestion and biogas production. In: Nandabalan YK, Garg VK, Labhsetwar NK, Singh A, editors. Zero Waste Biorefinery. Singapore: Springer; 2022. p. 575-91.

Olatunji KO, Madyira DM, Ahmed NA, Adeleke O, Ogunkunle O. Modeling the biogas and methane yield from anaerobic digestion of Arachis hypogea shells with combined pretreatment techniques using machine learning approaches. Waste Biomass Valor. 2023;14(4):1123-41.

Ghosh P, Shah G, Sahota S, Singh L, Vijay VK. Chapter 7 - Biogas production from waste: technical overview, progress, and challenges. In: Singh L, Yousuf A, Mahapatra DM, editors. Bioreactors. Cambridge: Elsevier; 2020. p. 89-104.

Moya D, Aldás C, Jaramillo D, Játiva E, Kaparaju P. Waste-To-Energy technologies: an opportunity of energy recovery from Municipal Solid Waste, using Quito-Ecuador as case study. Energy Procedia. 2017;134:327-36.

Rasapoor M, Young B, Brar R, Sarmah A, Zhuang WQ, Baroutian S. Recognizing the challenges of anaerobic digestion: critical steps toward improving biogas generation. Fuel. 2020;261:116497.

Honest A, Saria J. Performance of experimental bio-digestion for pathological and biodegradable waste management at Mwananyamala Regional Referral Hospital Tanzania. J Environ Prot. 2020;11(10):838-47.

Qin W. Aspects of pretreated hospital waste biodegradation in landfills [dissertation]. Essen: University of Duisburg-Essen; 2004.

Zacharof AI, Butler AP. Stochastic modelling of landfill leachate and biogas production incorporating waste heterogeneity. Model formulation and uncertainty analysis. Waste Manag. 2004;24(5):453-62.

Saraswat M, Garg M, Bhardwaj M, Mehrotra M, Singhal R. Impact of variables affecting biogas production from biomass. IOP Conf Ser: Mater Sci Eng. 2019; 691:012043.

Safar KM, Bux MR, Aslam UM. Waste to energy: power generation potential of putrescible wastes by anaerobic digestion process at Hyderabad, Pakistan. J Mater Cycles Waste Manag. 2018;20:1239-47.

Yusuf MOL, Ify NL. The effect of waste paper on the kinetics of biogas yield from the co-digestion of cow dung and water hyacinth. Biomass Bioenergy. 2011;35(3):1345-51.

Gidarakos E, Havas G, Ntzamilis P. Municipal solid waste composition determination supporting the integrated solid waste management system in the island of Crete. Waste Manag. 2006;26(6):668-79.

Lawal IM, Ndagi A, Mohammed A, Saleh YY, Shuaibu A, Hassan I, et al. Proximate analysis of the waste-to-energy potential of municipal solid waste for sustainable renewable energy generation. Ain Shams Eng J. 2024;15(1):102357.

Safar KM, Bux MR, Aslam UM, Shankar BA, Goel RK. The feasibility of putrescible components of municipal solid waste for biomethane production at Hyderabad, Pakistan. Waste Manag Res. 2018;36(2):169-82.

Nwoke OA, Okonkwo WI, Echiegu EA, Okechukwu CH, Ugwuishiwu BO. Determination of the calorific value of municipal solid waste in Enugu, Nigeria and its potential for electricity generation. Agric Eng Int: CIGR J. 2020;22(2):86-97.

Haider MR, Zeshan, Yousaf S, Malik RN, Visvanathan C. Effect of the mixing ratio of food waste and rice husk co-digestion and substrate to inoculum ratio on biogas production. Bioresour Technol. 2015;190:451-7.

Çelik İ, Demirer GN. Biogas production from pistachio (Pistacia vera L.) processing waste. Biocatal Agric Biotechnol. 2015;4(4):767-72.

Feng L, Li Y, Chen C, Liu X, Xiao X, Ma X, et al. Biochemical methane potential (BMP) of vinegar residue and the influence of feed to inoculum ratios on biogas production. BioRes; 2013;8(2):2487-98.

Ferdeș M, Dincă MN, Moiceanu G, Zăbavă BȘ, Paraschiv G. Microorganisms and enzymes used in the biological pretreatment of the substrate to enhance biogas production: a review. Sustainability. 2020;12(17):7205.

Obileke K, Onyeaka H, Nwokolo N. Materials for the design and construction of household biogas digesters for biogas production: a review. Int J Energy Res. 2021;45(3):3761-79.

Obileke K, Mamphweli S, Meyer EL, Makaka G, Nwokolo N. Design and fabrication of a plastic biogas digester for the production of biogas from cow dung. J Eng. 2020;2020:1-11.

Xu F, Li Y, Ge X, Yang L, Li Y. Anaerobic digestion of food waste–challenges and opportunities. Bioresour Technol. 2018;247:1047-58.

Arabi M, Sbaa M, Vanclooster M, Darmous A. Impact of the municipal solid waste typology on leachate flow under semi-arid climate–a case study. J Ecol Eng. 2020;21(6):94-101.

Gotmare M, Dhoble RM, Pittule AP. Biomethanation of dairy wastewater through UASB at mesophilic temperature range. Int J Adv Eng Sci Technol. 2011;8(1):1-9.