Desirability analysis of Commercial-off-the-shelf (COTS) alternative foaming agents for foamed concrete production

Main Article Content

Abstract

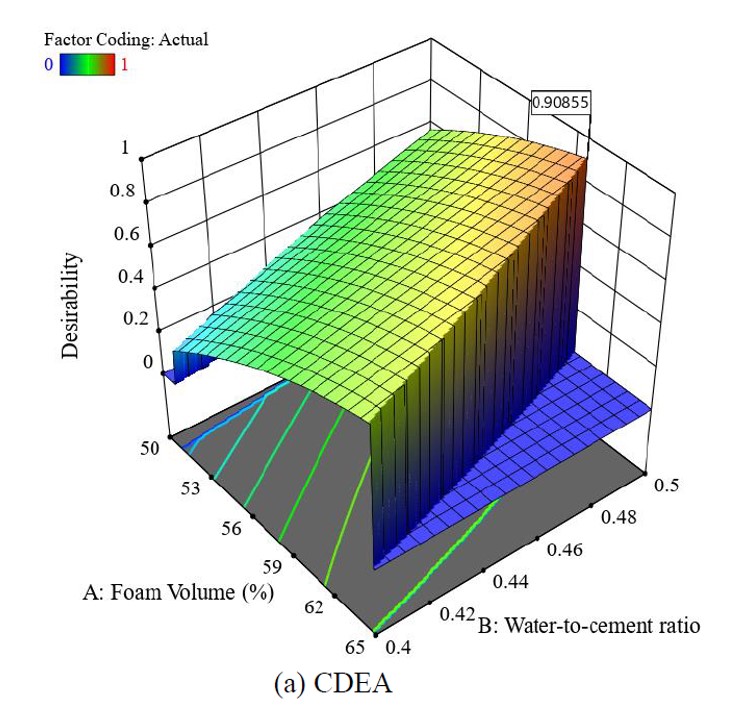

Foamed concrete (FC) offers potential for various lightweight construction applications, making the need for industry-standard foaming agents crucial in achieving its desired properties. However, the limited availability of quality foaming agents hampers FC’s widespread use in many economies. To address this, the potential of commercial-off-the-shelf (COTS) products capable of foaming has been explored in this paper. Three widely available COTS alternatives – Coconut Diethanolamide (CDEA), liquid detergent, and dishwashing liquid – were examined for FC production. Response Surface Methodology (RSM) and desirability analysis were employed to differentiate the effects of these COTS alternatives on various FC properties. Moreover, adjusting additional factors like foam volume, water-to-cement ratio, and maximum aggregate size – known influencers of FC properties – during the experiments revealed distinct impacts of each COTS alternative foaming agent on FC properties. Results revealed that FCs exhibiting highest compressive strengths are those made using CDEA, then followed by liquid detergent, and dishwashing liquid. In terms of absorption, FC samples made using CDEA exhibited the lowest values, followed by liquid detergent, then dishwashing liquid. In terms of unit cost, FC samples made using CDEA is the most economical, followed dishwashing liquid, then liquid detergent. However, regardless of the type of COTS alternative foaming the impact of FC density and CO2 emission equivalence values is similar. Furthermore, desirability analysis identified that CDEA yields the most desirable FC with optimal values for factors such as foam volume of about 60.073%, water-cement ratio of about 0.50, and maximum aggregate size of 1.611mm. Liquid detergent and dishwashing liquid also yields combinations of input factors which can produce FC conforming to corresponding ASTM standards for foamed concrete but with lower desirability. In conclusion, the investigation demonstrated the potential effectiveness of locally available COTS alternative foaming agents in FC production, contributing to their practical utilization and promoting more sustainable construction materials.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

Worrell E, Price L, Martin N, Hendriks C, Meida LO. Carbon dioxide emissions from the global cement industry. Annu Rev Energy Environ. 2001;26:303-29.

Ma S, Henry M, Opon J. Exploring the experimental design and statistical modeling of cementitious composite systems using various sampling methods. J Adv Concr Technol. 2021;19(5):501-18.

Awolusi TF, Oke OL, Akinkurolere OO, Sojobi AO. Application of response surface methodology: predicting and optimizing the properties of concrete containing steel fibre extracted from waste tires with limestone powder as filler. Case Stud Constr Mater. 2019;10:e00212.

Calis G, Yildizel SA, Erzin S, Tayeh BA. Evaluation and optimisation of foam concrete containing ground calcium carbonate and glass fibre (experimental and modelling study). Case Stud Constr Mater. 2021;15:e00625.

Fu Y, Wang X, Wang L, Li Y. Foam concrete: a state-of-the-art and state-of-the-practice review. Adv Mater Sci Eng. 2020;2020:1-25.

Zhao WS, Chen WZ, Tan XJ, Huang S. Study on foamed concrete used as seismic isolation material for tunnels. Mater Res Innov. 2013;17(7):465-72.

Selija K, Gandhi ISR. Comprehensive investigation into the effect of the newly developed natural foaming agents and water to solids ration on foam behavior. J Build Eng. 2022;58:105042.

Ramamurthy K, Kunhanandan Nambiar EK, Indu Siva Ranjani G. A classification of studies on properties of foam concrete. Cem Concr Compos. 2009;31(6):388-96.

Mugahed Amran YH, Farzadnia N, Abang Ali AA. Properties and applications of foamed concrete; a review. Constr Build Mater. 2015;101:990-1005.

Newman J, Owens P. Properties of lightweight concrete. In: Newman J, Choo BS, editors. Advanced Concrete Technology. Oxford: Butterworth-Heinemann; 2003. p. 3-29.

Amran M, Fediuk R, Vatin N, Lee YH, Murali G, Ozbakkaloglu T, et al. Fibre-reinforced foamed concretes: a review. Materials. 2020;13(19):4323.

Lim SK, Tan CS, Li B, Ling TC, Hossain MU, Poon CS. Utilizing high volumes quarry wastes in the production of lightweight foamed concrete. Constr Build Mater. 2017;151:441-8.

Waheed A, Arshid MU, Mehboob S, Ahmad A, Sultan T. Preparation of low-cost foam concrete using detergent. Technical Journal (UET Taxila). 2019;24(4):1-7.

McGee K. How to make concrete foam [Internet]. 2021 [cited 2021 Dec 10]. Available from: https://www.hunker.com/12000912/how-to-make-concrete-foam.

Ranjani IS, Ramamurthy K. Relative assessment of density and stability of foam produced with four synthetic surfactants. Mater Struct. 2010;43(10):1317-1325.

Sinkhonde D, Onchiri RO, Oyawa WO, Mwero JN. Response surface methodology-based optimization of cost and compressive strength of rubberized concrete incorporating burnt clay brick powder. Heliyon. 2021;7(12):e08565.

ASTM. ASTM C595-08a: Standard specification for blended hydraulic cements. West Conshohocken: ASTM International; 2010.

ASTM. ASTM C1602/C1602M-22: Standard specification for mixing water used in the production of hydraulic cement concrete. West Conshohocken: ASTM International; 2022.

ASTM. ASTM C33/C33M-18: Standard specification for concrete aggregates. West Conshohocken: ASTM International; 2023.

ASTM. ASTM C128-22: Standard test method for relative density (specific gravity) and absorption of fine aggregates. West Conshohocken: ASTM International; 2023.

Hashim M, Tantray M. Comparative study on the performance of protein and synthetic-based foaming agents used in foamed concrete. Case Stud Constr Mater. 2021;14:e00524.

Amran M, Lee YH, Vatin N, Fediuk R, Poi-Ngian S, Lee YY, et al. Design efficiency, characteristics, and utilization of reinforced foamed concrete: a review. Crystals. 2020;10(10):948.

Li Z, Yuan H, Gao F, Zhang H, Ge Z, Wang K, et al. A feasibility study of low cement content foamed concrete using high volume of waste lime mud and fly ash for road embankment. Materials (Basel). 2021;15(1):86.

Safawi MI, Taib SNL, Hua LP, Rashidi A. Investigating an optimum mixing method to produce foam concrete fulfilling the workability, density, shrinkage, strength and total volume. In: Mohammed BS, Shafiq N, Rahman M. Kutty S, Mohamad H, Balogun AL, editors. ICCOEE2020. Lecture Notes in Civil Engineering, vol 132. Singapore: Springer; 2021. p. 524-33.

American Concrete Institute. ACI PRC-211.1-22: Selecting proportions for normal-density and high-density concrete – guide. Farmington Hills: ACI; 2022.

Raheem AA, Soyingbe AA, Emenike AJ. Effect of curing methods on density and compressive strength of concrete. Int J Appl Sci Technol. 2013;3(4):55-64.

Chen X, Wu S, Zhou J. Compressive strength of concrete cores with different lengths. J Mater Civ Eng. 2014;26(7):04014027.

University of Wisconsin-Madison. Curiosities: What’s the difference between dishwasher detergent, laundry detergent and dish soap? why aren’t they interchangeable?. Madison: University of Wisconsin-Madison; 2010.

Jain JA, Seth A, DeCristofaro N. Environmental impact and durability of carbonated calcium silicate concrete. Proc Inst Civ Eng: Constr Mater. 2019;172(4):179-91.

Seddik Meddah M. Recycled aggregates in concrete production: engineering properties and environmental impact. MATEC Web Conf. 2017;101:05021.

Schowanek D, Borsboom-Patel T, Bouvy A, Colling J, de Ferrer JA, Eggers D, et al. New and updated life cycle inventories for surfactants used in European detergents: summary of the ERASM surfactant life cycle and ecofootprinting project. Int J Life Cycle Assess. 2018;23:867-86.

de Lapuente Díaz de Otazu RL, Akizu-Gardoki O, de Ulibarri B, Iturrondobeitia M, Minguez R, Lizundia E. Ecodesign coupled with life cycle assessment to reduce the environmental impacts of an industrial enzymatic cleaner. Sustain Prod Consum. 2022;29:718-29.

ASTM. ASTM C642-21: Standard test method for density, absorption, and voids in hardened concrete. West Conshohocken: ASTM International; 2022.

ASTM. ASTM C109/C109M-20: Standard test method for compressive strength of hydraulic cement mortars (using 2-in or [50-mm] cube specimens). West Conshohocken: ASTM International; 2020.

ASTM. ASTM C869/C869M-11: Standard specification for foaming agents used in making preformed foam for Cellular Concrete. West Conshohocken: ASTM International; 2016.

Aaslyng D, Gormsen E, Malmos H. Mechanistic studies of proteases and lipases for the detergent industry. J Chem Technol Biotechnol. 1991;50(3):321-30.

Zhang SP, Zong L. Evaluation of relationship between water absorption and durability of concrete materials. Adv Mater Sci Eng. 2014;2014:1-8.

Gökçe HS, Hatungimana D, Ramyar K. Effect of fly ash and silica fume on hardened properties of foam concrete. Constr Build Mater. 2019;194:1-11.