Enhancing of the rapid evaluation of sugarcane energy content for energy cane varieties selection purposes in breeding program using Near-Infrared spectroscopy (NIRS)

Main Article Content

Abstract

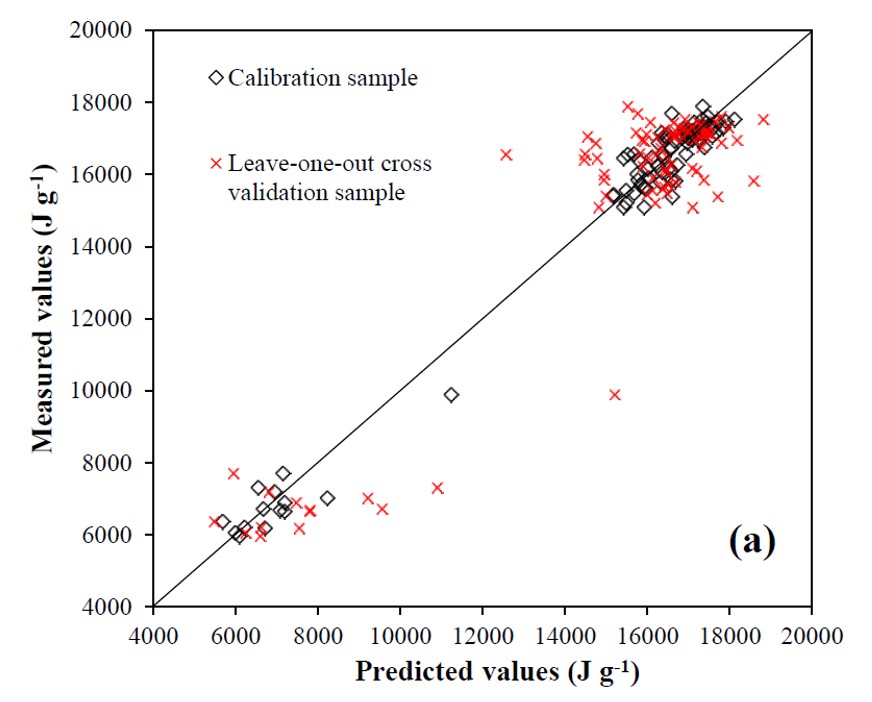

The integration of Near-Infrared spectroscopy (NIRs) as a predictive tool for rapidly assessing the gross calorific value (GCV) of dried shredded sugarcane addresses a significant bottleneck in sugarcane breeding programs. A total of 110 samples were collected, and a lab-type Fourier Transform near infrared (FT-NIR) spectrometer operating across a wavenumber range of 12,800 to 3,600 cm-1 was utilized for spectral acquisition. This study explored various variable selection algorithms with partial least squares (PLS) regression for model development. Variable selection methods included variable importance in projection (VIP), successive projections algorithm (SPA), genetic method (GA), and correlation (r). The r-PLS algorithm along with standard normal variate and first derivative (SNV + D1) pre-treatment yielded a highly effective model exhibiting a coefficient of determination in prediction (R2p) of 0.88 and the root mean square error of prediction (RMSEP) of 278.0 J/g. This study showed that the NIRs could provide a reliable method for rapid, fairly accurate, and precise GCV estimation. However, future research should investigate the use of additional modeling algorithms, such as non-linear regression, to improve model accuracy and utilize sample data with an evenly spread range of GCV values to validate the model performance with greater confidence.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

Bocci E, Di Carlo A, Marcelo D. Power plant perspectives for sugarcane mills. Energy. 2009;34(5):689-98.

Carvalho-Netto OV, Bressiani JA, Soriano HL, Fiori CS, Santos JM, Barbosa GV, et al. The potential of the energy cane as the main biomass crop for the cellulosic industry. Chem Biol Technol Agric.2014;1:1-8.

Roach BT. Origin and improvement of the genetic base of sugarcane. Proceeding of Australian Society of Sugar Cane Technologists; 1989 May 2-5; Tweed Heads, Australia. p. 34-47.

Nakawajana N, Posom J, Paeoui J. Prediction of higher heating value, lower heating value and ash content of rice husk using FT-NIR spectroscopy. Eng J. 2018;22(5):45-56.

Sirisomboon P, Funke A, Posom J. Improvement of proximate data and calorific value assessment of bamboo through near infrared wood chips acquisition. Renew Energy. 2020;147:1921-31.

Posom J, Shrestha A, Saechua W, Sirisomboon P. Rapid non-destructive evaluation of moisture content and higher heating value of Leucaena leucocephala pellets using near infrared spectroscopy. Energy. 2016;107:464-72.

Posom J, Phuphaphud A, Saengprachatanarug K, Maraphum K, Saijan S, Pongkan K, et al. Real-time measuring energy characteristics of cane bagasse using NIR spectroscopy. Sens Bio-Sens Res. 2022;38:100519.

Phuphaphud A, Saengprachatanarug K, Posom J, Taira E, Panduangnate L. Prediction and classification of energy content in growing cane stalks for breeding programmes using visible and shortwave near infrared. Sugar Tech. 2022;24(5):1497-509.

Baillères H, Davrieux F, Ham-Pichavant F. Near infrared analysis as a tool for rapid screening of some major wood characteristics in a eucalyptus breeding program. Ann For Sci. 2002;59:479-90.

Yeh TF, Yamada T, Capanema E, Chang HM, Chiang V, Kadla JF. Rapid screening of wood chemical component variations using transmittance near-infrared spectroscopy. J Agric Food Chem. 2005;53(9):3328-32.

Chea C, Saengprachatanarug K, Posom J, Wongphati M, Taira E. Sugarcane canopy detection using high spatial resolution UAS images and digital surface model. Eng Appl Sci Res. 2019;46(4):312-7.

Jessup RS. Precise measurement of heat of combustion with a bomb calorimeter. Washington: National Bureau of standard; 1960.

Williams P, Antoniszyn J, Manley M. Near infrared technology: getting the best out of light. Stellenbosc: African Sun Media; 2019.

Taira E, Ueno M, Furukawa N, Tasaki A, Komaki Y, Nagai JI, et al. Networking system employing near infrared spectroscopy for sugarcane payment in Japan. J Near Infrared Spectrosc. 2013;21(6):477-83.

Maraphum K, Ounkeaw A, Kasemsiri P, Hiziroglu S, Posom J. Wavelengths selection based on genetic algorithm (Ga) and successive projections algorithms (spa) combine with pls regression for determination the soluble solids content in nam-dokmai mangoes based on near infrared spectroscopy. Eng Appl Sci Res. 2022;49(1):119-26.

Sammut C, Webb GI, editors. Leave-One-Out Cross-Validation. Encyclopedia of Machine Learning. Boston: Springer; 2010. p. 600-1.

Sirisomboon P, Posom J. On-line measurement of activation energy of ground bamboo using near infrared spectroscopy. Renew Energy. 2019;133:480-8.

Posom J, Sirisomboon P. Evaluation of lower heating value and elemental composition of bamboo using near infrared spectroscopy. Energy. 2017;121:147-58.

Zornoza R, Guerrero C, Mataix-Solera J, Scow KM, Arcenegui V, Mataix-Beneyto J. Near infrared spectroscopy for determination of various physical, chemical and biochemical properties in Mediterranean soils. Soil Biol Biochem. 2008;40(7):1923-30.

Workman J, Weyer L. Practical guide to interpretive near-infrared spectroscopy. Boca Raton: CRC Press; 2007.

Wang J, Wang J, Chen Z, Han D. Development of multi-cultivar models for predicting the soluble solid. Postharvest Biol Technol. 2017;129:143-51.

Filho GR, de Assunção RMN, Vieira JG, da S Meireles C, Cerqueira DA, da Silva Barud H, et al. Characterization of methylcellulose produced from sugar cane bagasse cellulose: crystallinity and thermal properties. Polym Degrad Stab. 2007;92(2):205-10.

Lin Z, Li S, Huang J. Natural cellulose substance based energy materials. Chem Asian J. 2021;16(5):378-96.

Hu L, Xu S, Zhao Z, Yang Y, Peng Z, Yang M, et al. Ynamides as racemization-free coupling reagents for amide and peptide synthesis. J Am Chem Soc. 2016;138(40):13135-8.