Influence of laminar and turbulent flow on signal response of gas sensors in electronic nose chamber for detecting rancid odor in brown rice (cv. Khao Dawk Mali 105)

Main Article Content

Abstract

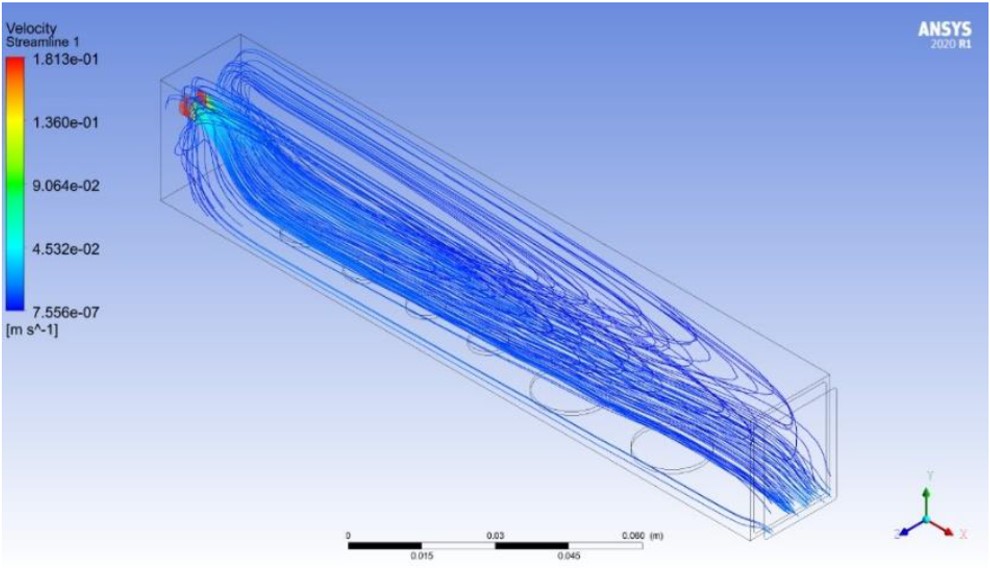

The aim of this research was to investigate the influence of flow pattern of the gas carrier inside the electronic nose chamber on the response rate of the signal from an array of gas sensors. The gas sensors in the electronic nose chamber were tested with laminar flow and turbulent flow. The principles of Reynolds number and the Navier-Stokes equation were employed to calculate and model the airflow in Computational Fluid Dynamics (CFD) simulations. The simulated airflow was compared to the actual airflow using smoke as a visual indicator to indicate the type of flow. Variables and conditions derived from the flow patterns were used in an actual experiment of electronic nose to detect specific odor compounds in brown rice (cv. KDML105). The six sensors were installed in an electronic nose chamber. The signals from the experiment were then used to determine the most effective sensor response between laminar and turbulent flow. Significantly different results were observed between the two flow patterns with a p-value < 0.05 for five out of six sensors. Additionally, the analysis of the rate of signal change indicated that the laminar flow pattern had higher values compared to the turbulent flow pattern.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

Deshmukh S, Bandyopadhyay R, Bhattacharyya N, Pandey RA, Jana A. Application of electronic nose for industrial odors and gaseous emissions measurement and monitoring--an overview. Talanta. 2015;144:329-40.

Gliszczyńska-Świgło A, Chmielewski J. Electronic nose as a tool for monitoring the authenticity of food. A review. Food Anal Methods. 2017;10(6):1800-16.

Baietto M, Wilson AD. Electronic-Nose applications for fruit identification, ripeness and quality grading. Sensors (Basel). 2015;15(1):899-931.

Karakaya D, Ulucan O, Turkan M. Electronic nose and its applications: a survey. Int J Autom Comput. 2020;17(2):179-209.

Eusebio L, Capelli L, Sironi S. Electronic nose testing procedure for the definition of minimum performance requirements for environmental odor monitoring. Sensors. 2016;16(9):1548.

Westenbrink E, Arasaradnam RP, O'Connell N, Bailey C, Nwokolo C, Bardhan KD, et al. Development and application of a new electronic nose instrument for the detection of colorectal cancer. Biosens Bioelectron. 2015;67:733-8.

Taştan M, Gökozan H. Real-Time monitoring of indoor air quality with internet of things-based e-nose. Appl Sci. 2019;9(16):3435.

Suchorab Z, Frac M, Guz L, Oszust K, Lagod G, Gryta A, et al. A method for early detection and identification of fungal contamination of building materials using e-nose. PLoS One. 2019;14(4):e0215179.

Gobbi E, Falasconi M, Zambotti G, Sberveglieri V, Pulvirenti A, Sberveglieri G. Rapid diagnosis of Enterobacteriaceae in vegetable soups by a metal oxide sensor based electronic nose. Sens Actuators B Chem. 2015;207:1104-13.

Loutfi A, Coradeschi S, Mani GK, Shankar P, Rayappan JBB. Electronic noses for food quality: a review. J Food Eng. 2015;144:103-11.

Liang Z, Tian F, Zhang C, Sun H, Liu X, Yang SX. A correlated information removing based interference suppression technique in electronic nose for detection of bacteria. Anal Chim Acta. 2017;986:145-52.

Pearce TC, Schiffman SS, Nagle HT, Gardner JW. Handbook of machine olfaction: electronic nose technology. Weinheim: Wiley; 2003.

Neamsorn N, Changrue V, Kantakaew P, Promngam P. Electronic nose for classification of rancid odor in brown rice cv. Khao Dawk Mali 105. Agricultural Sci J. 2019;50(3):356-9. (In Thai)

Zou X, Wang C, Luo M, Ren Q, Liu Y, Zhang S, et al. Design of electronic nose detection system for apple quality grading based on computational fluid dynamics simulation and k-nearest neighbor support vector machine. Sensors. 2022;22(8):2997.

Loksupapaiboon K, Suvanjumrat C. Validation of wall functions for two-equation turbulence model of OpenFOAM. Eng J Res Dev. 2020;31(2):105-17. (In Thai)

Launder BE, Spalding DB. The numerical computation of turbulent flows. Comput Methods Appl Mech Eng. 1974;3(2):269-89.

Goody BA, Milton MJ. High-accuracy gas flow dilutor using mass flow controllers with binary weighted flows. Meas Sci Technol. 2002;13(7):1138.

Zeng Y, Fang J. Numerical simulation and experimental study on gas mixing in a gas chamber for sensor evaluation. Meas: Sens. 2021;18:100338.

Wang X, Qian C, Zhao Z, Li J, Jiao M. A novel gas recognition algorithm for gas sensor array combining Savitzky–Golay smooth and image conversion route. Chemosensors. 2023;11(2):96.

Brahim K, Mourad B, Afif EC, Ali B. Control of smoke flow in a tunnel. J Appl Fluid Mech. 2013;6(1):49-60.

Blixt Y, Borch E. Using an electronic nose for determining the spoilage of vacuum-packaged beef. Int J Food Microbiol. 1999;46(2):123-34.

Kumar K, Rajput NS, Shvetsov AV, Saif A, Sahal R, Alsamhi SH. ID2S4FH: A novel framework of intelligent decision support system for fire hazards. Fire. 2023;6(7):248.

Di Francesco F, Falcitelli M, Marano L, Pioggia G. A radially symmetric measurement chamber for electronic noses. Sens Actuators B: Chem. 2005;105(2):295-303.

Kumar K, Rajput NS. Analysis space transformation based electronic nose for efficient detection and monitoring of volatile organic compounds, gases/odors in smart homes. Eur Chem Bull. 2023;12(Special Issue 7):513-28.

Harmouzi M, Amari A, Masmoudi L. Conception and simulation of an electronic nose prototype for olfactory acquisition. Adv Sci Technol Eng Syst J. 2023;8(1):101-7.

Chen Y, Xia W, Chen D, Zhang T, Song T, Zhao W, et al. A qualitative and quantitative analysis strategy for continuous turbulent gas mixture monitoring. Chemosensors. 2022;10(12):499.

Borowik P, Grzywacz T, Tarakowski R, Tkaczyk M, Slusarski S, Dyshko V, et al. Development of a low-cost electronic nose with an open sensor chamber: application to detection of ciboria batschiana. Sensors. 2023;23(2):627.