Comparative study on material models for BS 080M46 medium carbon steel

Main Article Content

Abstract

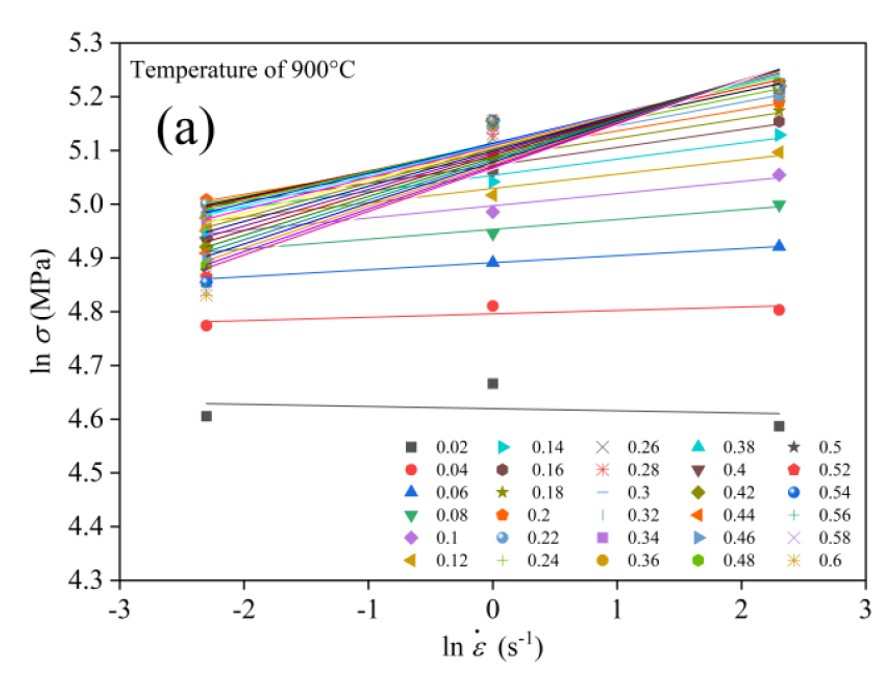

This work focused on studying the flow behavior of BS 080M46 medium carbon steel through hot compression tests, covering a deformation temperature of 900, 1000, 1100, and 1200°C and strain rates varying from 0.1 to 10 s-1. The purpose of this work was to effectively predict the flow behavior of the material at elevated temperatures using two different constitutive models: the Arrhenius-based and the Hansel-Spittel model. The application of the regression method involved fitting the experimental stress-strain data to obtain the material constants for these models. A comparison was made between the experimental and predicted flow stresses based on the two constitutive models, demonstrating a strong correlation with the experimental data. The developed Arrhenius-based constitutive model exhibited greater accuracy and reliability in its predictability compared to the Hansel-Spittel constitutive model, with AARE of 7.5231%, an RMS of 7.3565 MPa, and an R value of 0.98450. To further validate the predictive capability of the two constitutive models, they were incorporated into finite element software to conduct simulations of the hot compression tests. Comparing the actual load-displacement curves with those obtained curves obtained through finite element simulations revealed a comparable consistency between the predicted and actual load-displacement curves.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

Jantepa N, Suranuntchai S. Investigation of hot deformation behavior of SNCM8 alloy steel. World J Mech. 2021;11(3):17-33.

Altan T, Ngaile G, Shen G. Cold and hot forging: fundamentals and applications. Materials Park: ASM International; 2004.

Siripath N, Suranuntchai S, Sucharitpwatskul S. Cylindrical billet size optimization for hot closed-die forging of the upper ball joint. Key Eng Mater. 2023;946:9-14.

Patnamsetty M, Saastamoinen A, Somani MC, Peura P. Constitutive modelling of hot deformation behaviour of a CoCrFeMnNi high-entropy alloy. Sci Technol Adv Mater. 2020;21(1):43-55.

Prasad YVRK, Rao KP, Sasidhar S. Hot Working guide: a compendium of processing maps. 2nd ed. Materials Park: ASM International; 2015.

Liang Q, Liu X, Li P, Ding P, Zhang X. Development and application of high-temperature constitutive model of HNi55-7-4-2 Alloy. Metals. 2020;10(9):1250.

Sellars CM, McTegart WJ. On the mechanism of hot deformation. Acta Metallurgica. 1966;14(9):1136-8.

Kumar N, Kumar S, Nath SK. Determination of Zener-Hollomon parameter of a low alloy medium carbon steel under hot compression physical simulation. Proceedings of the 4th International Conference on Thermo-mechanical Simulation and Processing of Steels (SimPro 16); 2016 Feb 10-12; Ranchi, India. p. 346-52.

Li HZ, Zhang XM, Chen MG, Liu Y, Gao H. Hot deformation behavior of 2519 Al alloy during isothermal compression. Mater Sci Forum. 2007;546-549:749-54.

Xiao ZB, Wang Q, Huang YC, Hu J, Li M. Hot deformation characteristics and processing parameter optimization of Al–6.32Zn–2.10Mg alloy using constitutive equation and processing map. Metals. 2021;11(2):360.

Dandekar TR, Khatirkar RK, Gupta A, Bibhanshu N, Bahdauria A, Suwas S. Strain rate sensitivity behaviour of Fe–21Cr-1.5Ni–5Mn alloy and its constitutive modelling. Mater Chem Phys. 2021;271:124948.

Yin F, Hua L, Mao H, Han X. Constitutive modeling for flow behavior of GCr15 steel under hot compression experiments. Mater Des. 2013;43:393-401.

Hansel A, Spittel T. Kraft- und Arbeitsbedarf bildsamer Formgeburgsverfahren. Leipzig: VEB DeutscherVerlag fur Grundstoffindustrie; 1978. (In German)

Chen X, Wang N, Ma X, Zhou H. Hot deformation behaviour and Hansel-Spittel constitutive model of Cr5 alloy for heavy backup roll. Int J Comput Mater Sci Surf Eng. 2018;7(3/4):205-17.

Chen X, Du Y, Du K, Lian T, Liu B, Li Z, et al. Identification of the constitutive model parameters by inverse optimization method and characterization of hot deformation behavior for ultra-supercritical rotor steel. Materials. 2021;14(8):1958.

Cyganek Z, Tkocz M. The effect of AZ31 alloy flow stress descriotion on the accuracy of forward extrusion fe simulation results. Arch Metall Mater. 2012;57(1):199-204.

Chadha K, Shahriari D, Jahazi M. An approach to develop hansel–spittel constitutive equation during ingot breakdown operation of low alloy steels. In: Muruganant M, Chirazi A, Raj B, editors. Frontiers in Materials Processing. Applications, Research and Technology. Singapore: Springer; 2018. p. 239-46.

Chen X, Lian T, Zhang B, Du Y, Du K, Liu B, et al. The parameters identification of high-temperature constitutive model based on inverse optimization method and 3D processing map of Cr8 alloy steel. Materials. 2021;14(9):2216.

Sanrutsadakorn A, Uthaisangsuk V, Suranuntchai S, Thossatheppitak B. Constitutive modeling of flow behaviour of AISI 4340 steel under hot working conditions. Appl Mech Mater. 2013;249-250:863-9.

Sanrutsadakorn A, Uthaisangsuk V, Suranuntchai S, Thossatheppitak B. Investigation of hot deformation characteristics of AISI 4340 steel using processing map. Adv Mater Res. 2013;683:301-6.

Thossatheppitak B, Uthaisangsuk V, Mungsuntisuk P, Suranuntchai S, Manonukul A. Flow behaviour of Nickel Aluminium Bronze under hot deformation. Mater Sci Eng A. 2014;604:183-90.

Aungsusiripong A, Suranuntchai S, Uthaisangsuk V. Constitutive modeling of flow stress of MAB alloy. Adv Mater Res. 2015;1101:442-5.

Banerjee S, Robi PS, Srinivasan A, Kumar LP. High temperature deformation behavior of Al–Cu–Mg alloys micro-alloyed with Sn. Mater Sci Eng A. 2010;527(10-11):2498-503.

Wang M, Li Y, Wang W, Zhou J, Chiba A. Quantitative analysis of work hardening and dynamic softening behavior of low carbon alloy steel based on the flow stress. Mater Des. 2013;45:384-92.

Chen X, Zhang B, Du Y, Liu M, Bai R, Si Y, et al. Constitutive model parameter identification based on optimization method and formability analysis for Ti6Al4V alloy. Materials. 2022;15(5):1748.