Recovery of valuable metals from NMC-811 li-ion battery waste with froth flotation and hydrometallurgical extraction

Main Article Content

Abstract

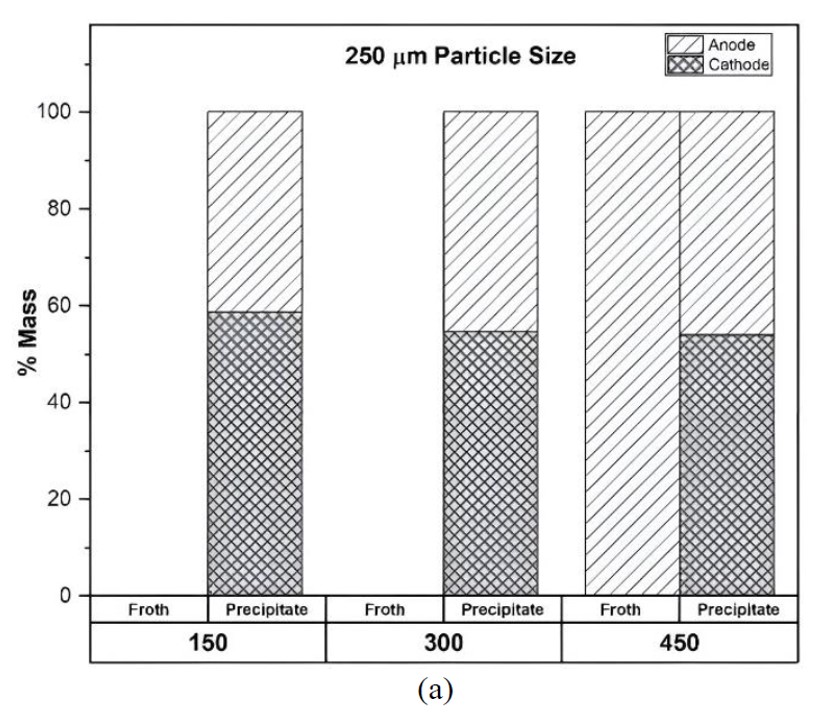

In this research, the primary objective is to study the recycling process of spent lithium-ion batteries (LIBs) for the recovery of valuable metals - specifically, nickel, manganese, and cobalt. This is accomplished through a comprehensive hydrometallurgical process that integrates froth flotation, acid leaching, and solvent extraction. The optimization of the flotation phase is a pivotal aspect of this study, with a focus on parameters like particle size and collector concentration. This optimization leads to a remarkable separation efficiency, evident in the recovery of 99.3% of the anode mass in the froth and 78.2% of the cathode mass in the precipitate. Notably, nickel emerges as the standout performer, with an extraordinary extraction efficiency of 99.97%. Nickel precipitates as an ammonium nickel sulfate crystals after solvent extraction due to supersaturation. These findings underscore the considerable potential of froth flotation and hydrometallurgical techniques as a sustainable, low-energy solution for recycling valuable metals sourced from spent LIBs.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

Vieceli N, Casasola R, Lombardo G, Ebin B, Petranikova M. Hydrometallurgical recycling of EV lithium-ion batteries: effects of incineration on the leaching efficiency of metals using sulfuric acid. Waste Manag. 2021;125:192-203.

Benjamasutin P, Promphan R. Recycling of lithium-ion batteries. Determination of optimal parameters for the application of hydrogen peroxide as reducing agent in the leaching process [thesis]. Gothenburg: Chalmers University of Technology; 2020.

International Energy Agency (IEA). The role of critical world energy outlook special report minerals in clean energy transitions. USA: International Energy Agency; 2022.

Melin HE. State of the art in reuse and recycling of lithium-ion batteries-a research review. London: Circular Energy Storage; 2019.

Assunção J. Hydrometallurgical processing of Li-ion batteries from electric vehicles [thesis]. Lisbon: University of Lisbon; 2019.

Samarukha I. Recycling strategies for end-of-life li-ion batteries from heavy electric vehicles [thesis]. Sweden: KTH Industrial Engineering and Management; 2020.

Ye Z, Qiu L, Yang W, Wu Z, Liu Y, Wang G, et al. Nickel-rich layered cathode materials for lithium-ion batteries. Chem Eur J. 2021;27(13):4249-69.

Folayan TO, Lipson AL, Durham JL, Pinegar H, Liu D, Pan L. Direct recycling of blended cathode materials by froth flotation process. Energy Technol. 2021;9(10):1-26.

Zhan R, Oldenburg Z, Pan L. Recovery of active cathode materials from lithium-ion batteries using froth flotation. Sustain Mater Technolo. 2018;17:1-9.

Hu Q, Xu L. An overview on lithium-ion batteries recycling processes. J Phys Conf Ser. 2021;1885:032031.

Verdugo L, Zhang L, Saito K, Bruckard W, Menacho J, Hoadley A. Flotation behavior of the most common electrode materials in Lithium-ion batteries. Sep Purif Technol. 2022;301:121885.

Vanderbruggen A. Lithium-ion batteries recycling with froth flotation – a study on characterization and liberation strategies [thesis]. Helsinki: Aalto University; 2022.

Wang S, Tian Y, Zhang X, Yang B, Wang F, Xu B, et al. A review of processes and technologies for the recycling of spent lithium-ion batteries. IOP Conf Ser Mater Sci Eng. 2020;782:022025.

Xuan W, Otsuki A, Chagnes A. Investigation of the leaching mechanism of NMC 811 (LiNi0.8Mn0.1Co0.1O2) by hydrochloric acid for recycling lithium ion battery cathodes. RSC Adv. 2019;9(66):38612-8.

Chen WS, Ho HH. Recovery of valuable metals from lithium-ion batteries NMC cathode waste materials by hydrometallurgical methods. Metals. 2018;8(5):1-16.

Bai Y, Muralidharan N, Sun YK, Passerini S, Whittingham MS, Belharouak I. Energy and environmental aspects in recycling lithium-ion batteries: concept of battery identity global passport. Mater Today. 2020;41:304-15.

Neumann J, Petranikova M, Meeus M, Gamarra JD, Younesi R, Winter M, et al. Recycling of lithium-ion batteries—current state of the art, circular economy, and next generation recycling. Adv Energy Mater. 2022;12(17):1-26.

Alipanah M, Saha AK, Vahidi E, Jin H. Value recovery from spent lithium-ion batteries: a review on technologies, environmental impacts, economics, and supply chain. Clean Technol Recycl. 2021;1(2):152-84.

Ji Y, Kpodzro EE, Jafvert CT, Zhao F. Direct recycling technologies of cathode in spent lithium-ion batteries. Clean Technol Recycl. 2021;1:124-51.

Wills BA, Finch JA. Chapter 12 - Froth flotation. In: Wills BA, Finch JA, editors. Wills’ Mineral Processing Technology. 8th ed. Amsterdam: Elsevier; 2016. p. 265-380.

Zhang G, Du Z, He Y, Wang H, Xie W, Zhang T. A sustainable process for the recovery of anode and cathode materials derived from spent lithium-ion batteries. Sustainability 2019;11(8):2363.

Zawisza B, Sitko R. Determination of lithium in mineral water samples by x-ray fluorescence spectrometry. Appl Spectrosc. 2011;65(10):1218-21.

Nguyen AV, Evans GM. Attachment interaction between air bubbles and particles in froth flotation. Exp Therm Fluid Sci. 2004;28(5):381-5.

Popova AN. Crystallographic analysis of graphite by x-ray diffraction. Coke Chem. 2017;60(9):361-5.

Li ZQ, Lu CJ, Xia ZP, Zhou Y, Luo Z. X-ray diffraction patterns of graphite and turbostratic carbon. Carbon. 2007;45(8):1686-95.

Yu J, He Y, Ge Z, Li H, Xie W, Wang S. A promising physical method for recovery of LiCoO2 and graphite from spent lithium-ion batteries: grinding flotation. Sep Purif Technol. 2018;190:45-52.

Or T, Gourley SWD, Kaliyappan K, Yu A, Chen Z. Recycling of mixed cathode lithium-ion batteries for electric vehicles: current status and future outlook. Carbon Energy. 2020;2(1):6-43.

Tang YC, Wang JZ, Shen YH. Separation of valuable metals in the recycling of lithium batteries via solvent extraction. Minerals. 2023;13(2):1-12.

Alvial-Hein G, Mahandra H, Ghahreman A. Separation and recovery of cobalt and nickel from end of life products via solvent extraction technique: A review. J Clean Prod. 2021;297:1-26.

Sist C, Demopoulos GP. Nickel hydroxide precipitation from aqueous sulfate media. JOM. 2003;55:42-6.