Bio-Based Composite from Sunflower Stalks for Building Wall Panels

DOI:

https://doi.org/10.69650/rast.2025.260769Keywords:

Agricultural Waste Recycling , Green Composite, Natural Latex, Sunflower ResidueAbstract

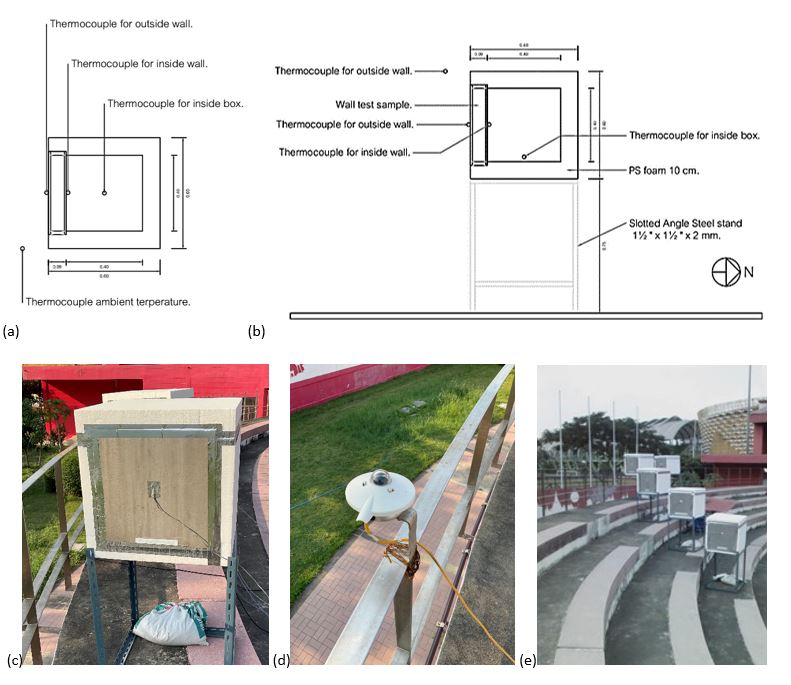

Burning sunflower stalks after harvesting could pose a significant environmental risk due to particulate matter 2.5 pollution. The use of low-cost recycled materials in building products is on trend. The objective of this study was to investigate a bio-composite made from sunflower stalks and sunflower bark using various ratios of natural latex as a binder and to compare the effects of hot ovens and hot compression. Three bio-composite-to-binder ratios of 1:4, 1:5, and 1:6 were compared. The physical, mechanical, thermal, and acoustic properties of the bio-composite were determined. The test box was used to evaluate the thermal performance of bio-composites. The bio-composites had a density similar to flat-pressed particleboards. The moisture content varied from 6.01 to 14.20%, with only the 1:5 and 1:6 sunflower stalk bio-composites by hot compression having a moisture content higher than 13%. Thickness swelling ranged from 5.63% to 12.03%. All composites had a fire resistance that passed the UL94HB standard, classified as at least flame retardant. As natural latex increases, the water absorption of sunflower stalks decreases while at the same time increasing fire resistance. The thermal conductivity coefficient ranged between 0.117 and 0.161 W/mK. The hot-compressed 1:6 sunflower bark bio-composite exhibited a room temperature profile that was similar to that of the MDF board. The hot compression method revealed better results in density, water absorption, flexural strength, and flexural modulus than the hot oven method.

References

İnce, A., Uğurluay, S., Güzel, E. and Özcan, M.T., Bending and shearing characteristics of sunflower stalk residue. Biosystems Engineering. 92 (2005) 175-181, doi: https://doi.org/10.1016/j.biosystemseng.2005.07.003.

Karaman, S., Sahin,S., Gunal, H., Ibrahim, O. and Ersahin, S., Use of sunflower stalk and pumice in gypsum composites to improve thermal properties. Journal of Applied Sciences 6 (2006) 1322-1326, doi: http://dx.doi.org/10.3923/jas.2006.1322.1326.

Kocaman, I., Sisman, C.B. and Gezer, E., Investigation the using possibilities of some mineral-bound organic composites as thermal insulation material in rural buildings. Scientific Research and Essays. 6 (2011) 1673-1680, doi: https://doi.org/10.5897/SRE11.283

Sun, S., Mathias, J.D., Toussaint, E. and Grédiac, M., Hydromechanical characterization of sunflower stems. Industrial Crops and Products. 46 (2013) 50-59, doi: https://doi.org/10.1016/j.indcrop.2013.01.009.

Wen, J., Wang, Q., Jin, Q. and Pan Z., Study on the structure, composition and performance of natural polymer. Functional Materials Letters. 3 (2010) 207-212, doi: https://doi.org/10.1142/S1793604710001263.

Binici, H., Aksogan, O., Dincer, A., Luga, E., Eken, M. and Isikaltun, O., The possibility of vermiculite, sunflower stalk and wheat stalk using for thermal insulation material production. Thermal Science and Engineering Progress 18 (2020) 100567, doi: https://doi.org/10.1016/j.tsep.2020.100567.

da Rosa, L. C., Santor C. G., Lovato, A., da Rosa C. S. and Güths, S., Use of rice husk and sunflower stalk as a substitute for glass wool in thermal insulation of solar collector. Journal of Cleaner Production. 104 (2015) 90-97, doi: https://doi.org/10.1016/j.jclepro.2015.04.127.

Mati-Baouche, N., De Baynast, H., Lebert, A., Sun S., Lopez-Mingo C. J. S., Leclaire, P. and Michaud, P., Mechanical, thermal and acoustical characterizations of an insulating bio-based composite made from sunflower stalks particles and chitosan. Industrial Crops and Products. 58 (2014) 244-250, doi: https://doi.org/10.1016/j.indcrop.2014.04.022.

Gopinathan, H., Jose, J., Peter, A., Mohan, C. C., Harishma, P. C., Narayanankutty, S. K. and Bhat, S. G., Amikacin sulfate loaded natural rubber latex films: Characterization and antibacterial performances. Results in Engineering. 23 (2024) 102795, doi: https://doi.org/10.1016/j.rineng.2024.102795.

Hejna, A., Wiśniewska, P., Kowalkowska-Zedler, D., Korol, J., Kosmela, P., Marć, M., Ezzati, P., Szostak, M. and Saeb, M. R., Waste printer ink as modifier for natural rubber/carbon black composites: No haste, use waste. Sustainable Materials and Technologies. 38 (2023) e00765, doi: https://doi.org/10.1016/j.susmat.2023.e00765.

Sakulkhaemaruethai, C., Jakarbutr, W. and Chailad, W., Accelerated Vulcanisation of Natural Rubber Latex Sheets Using Microwave Energy: Mechanical and Thermal Performance Improvements. Results in Engineering. 26 (2025) 105197, doi: https://doi.org/10.1016/j.rineng.2025.105197.

Brouard, Y., Belayachi, N., Hoxha, D., Ranganathan, N. and Méo, S., Mechanical and hygrothermal behavior of clay–Sunflower (Helianthus annuus) and rape straw (Brassica napus) plaster bio-composites for building insulation. Construction and Building Materials. 161 (2018) 196-207, doi: https://doi.org/10.1016/j.conbuildmat.2017.11.140.

TIS. 876-2547, Thai Industrial Standard for Flat Pressed Particleboards, (2004), ISBN 974-687-210-9.

TIS 178-2549, Thai Industrial Standards for Veneer Plywood, (2007), ISBN 978-974-292-355-6.

ASTM D1037-12, Standard test methods for evaluating properties of wood-base fiber and particle panel materials, ASTM International. (2020).

UL94 HB-TEST, Test for flammability of plastic materials for parts in devices and appliances, (2001), ISBN 0-7629-0082-2,1-52. Yzimgs. Online at: http://file.yzimgs.com/174750/20078119548234314385.pdf.

ASTM D790-17, Standard test methods for flexural properties of unreinforced and reinforced plastics and electrical insulating materials, ASTM International. (2017).

ISO 22007-2, Plastics -determination of thermal conductivity and thermal diffusivity — Part 2: Transient plane heat source (hot disc) method. iTeh Standards. (2015), Online at: https://cdn.standards.iteh.ai/samples/61190/6edb07c2735b47f783d858a32d57034f/ISO-22007-2-2015.pdf.

ISO 10534-2, Acoustics -determination of sound absorption coefficient and impedance in impedance tubes – Part 2: Transfer-function method. iTeh Standards. (1998) Online at: https://cdn.standards.iteh.ai/samples/22851/2b999ad0cc6c40cd84063eb81ab70944/ISO-10534-2-1998.pdf.

Li, H., Zhong, K., Yu, J., Kang, Y. and Zhai, J. Z., Solar energy absorption effect of buildings in hot summer and cold winter climate zone, China. Solar Energy. 198 (2020) 519-528, doi: https://doi.org/10.1016/j.solener.2020.01.047.

Usubharatana, P. and Phungrassami, H., Life cycle assessment of bio-based thermal insulation materials formed by different methods. Environmental Engineering and Management Journal. 18 (2019) 1471-1486, doi: http://dx.doi.org/10.30638/eemj.2019.138.

Khedari, J., Charoenvai, S. and Hirunlabh, J., New insulating particleboards from durian peel and coconut coir. Building and environment. 38 (2003) 435-441, doi: https://doi.org/10.1016/S0360-1323(02)00030-6.

Jaktorn, C. and Jiajitsawat S., Production of thermal insulator from water hyacinth fiber and natural rubber latex. NU. International Journal of Science. 11 (2014) 31-41.

Chikhi, M., Agoudjil, B., Boudenne, A. and Gherabli, A., Experimental investigation of new biocomposite with low cost for thermal insulation. Energy and buildings. 66 (2013) 267-273, doi: https://doi.org/10.1016/j.enbuild.2013.07.019.

Benfratello, S., Capitano, C., Peri, G., Rizzo, G., Scaccianoce, G. and Sorrentino G., Thermal and structural properties of a hemp–lime biocomposite. Construction and building materials. 48 (2013) 745-754, doi: https://doi.org/10.1016/j.conbuildmat.2013.07.096.

Eschenhagen, A., Raj, M., Rodrigo, N., Zamora, A., Labonne, L., Evon, P. and Welemane H., Investigation of miscanthus and sunflower stalk fiber-reinforced composites for insulation applications. Advances in Civil Engineering. 2019 (2019) 1-7, doi: https://doi.org/10.1155/2019/9328087.

ISO 11654. Acoustics: sound absorbers for use in buildings: rating of sound absorption. iTeh Standards. (1997). Online at: https://cdn.standards.iteh.ai/samples/19583/f05ae41625eb4cb0b95611feccf6fda6/ISO-11654-1997.pdf.

Sadeghi, G., Pisello, A. L., Nazari, S., Jowzi, M. and Shama F., Empirical data-driven multi-layer perceptron and radial basis function techniques in predicting the performance of nanofluid-based modified tubular solar collector. Journal of Cleaner Production. 295 (2021) 1-14, doi: https://doi.org/10.1016/j.jclepro.2021.126409.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 School of Renewable Energy and Smart Grid Technology (SGtech)

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

All copyrights of the above manuscript, including rights to publish in any media, are transferred to the SGtech.

The authors retain the following rights;

1. All proprietary rights other than copyright.

2. Re-use of all or part of the above manuscript in their work.

3. Reproduction of the above manuscript for author’s personal use or for company/institution use provided that

(a) prior permission of SGtech is obtained,

(b) the source and SGtech copyright notice are indicated, and

(c) the copies are not offered for sale.