Optimization of Far Infrared Radiation Power for Roasting Coffee

Keywords:

Far Infrared, Radiation, Coffee Bean, Color, RoastingAbstract

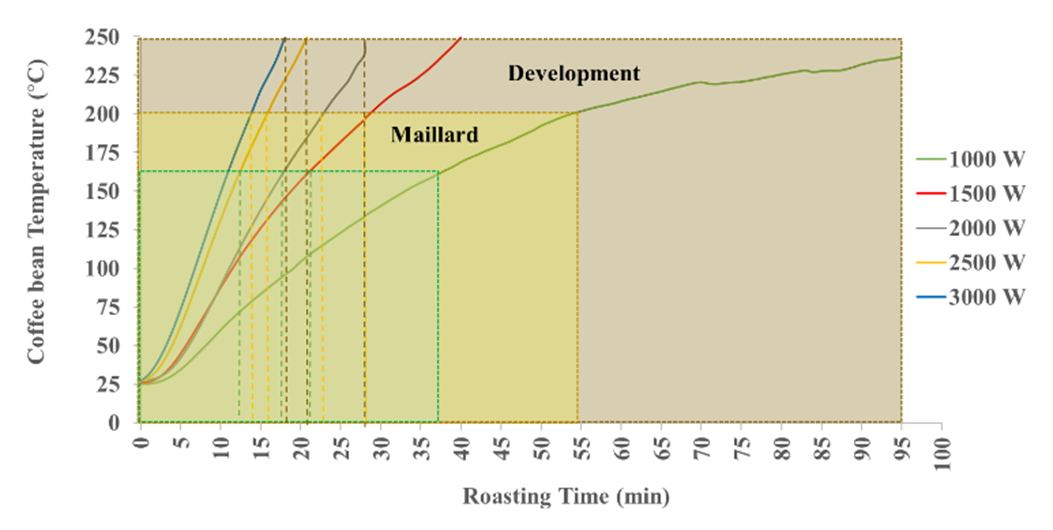

Investigating the possibility of using a Far Infrared heater to radiate heat sources for roasting coffee, this study measured the roasting temperature, roasting time, and color variation of a 1-kilogram coffee bean in a horizontal roaster coffee machine using different power heaters (1000, 1500, 2000, 2500, and 3000 W FIR). Comparing the results with consumer-acceptable roasted coffee colors (37.05 to 4.69 L*, 2.29 to 4.15 a*, and 2.70 to 6.29 b*)[1], it was observed that the coffee temperature roasted above 250°C with a moisture content of 9% (dry basis-db.). The findings demonstrated that as the FIR power increased, the coffee bean's temperature increased while the roasting time decreased. Moreover, the color attributes (CIE L*, a*, and b* values) decreased significantly with higher roasting temperatures and shorter times. The specific energy requirement varied at different FIR powers, with the minimum being 3750 J/g at 2500 W and the maximum at 6075 J/g at 1000 W, which could be attributed to the increased FIR power and sample surface temperature. This decrease in specific energy requirement was associated with reduced drying time. The respective roasting times for the FIR power heaters were as follows: 81 minutes for 1000 W, 40 minutes for 1500 W, 28 minutes for 2000 W, 20 minutes for 2500 W, and 18 minutes for 3000 W. These results indicate the potential of using Far Infrared heaters for efficient coffee roasting, offering control over temperature and roasting time to achieve desired color attributes and flavor profiles.

References

Mendes, L. C., de Menezes, H. C., Aparecida, M., & da Silva, A.P. (2001). Optimization of the roasting of robusta coffee (C. canephora cotillon) using acceptability tests and RSM. Food Quality and Preference, 12(2), 153-162.

Wang, N. (2012). Physicochemical Changes of Coffee Beans During Roasting (Doctoral dis-sertation). Ontario, CA: The University of Guelph.

Marija, J. R., Natalija, D. R., Cvetković, B., & Slavica ,G. (2012).Changes of physical proper-ties of coffee beans during roasting. Acta Periodica Technologica, 43,21-31.

Yang, J., Bingol G., Pan, Z., Brandl M. T., McHugh, T. H., & Yang, H. W. (2010). Infrared heating for dry-roasting and pasteurization of almonds. Journal of Food Engineering, 101(3), 273-280.

Tsai, C. F., & Jioe, I. P. J. (2021). The Analysis of Chlorogenic Acid and Caffeine Content and Its Correlation with Coffee Bean Color under Different Roasting Degrees and Sources of Coffee (Coffea arabica Typica). Processes, 9(11), 2040.

Pawar, S.B., & Pratape, V. M. (2017). Fundamentals of Infrared Heating and Its Application in Drying of Food Materials: A Review. Journal of Food Process Engineering, 40(1),12308.

Cullen, P. J., Tiwari, B. K., & Valdramidis, V. (2011). Novel Thermal and Non-Thermal Tech-nologies for Fluid Foods. Oxford, UK: Elsevier’s Science and Technology.

Huang, D., Yang, P., Tang, X., Luo, L., & Sunden, B. (2021). Application of infrared radia-tion in the drying of food products. Trends in Food Science & Technology, 110, 765-777.

Wu, B., Ma, H., Qu, W., Wang, B., Zhang, X., Wang, P., Wang, J., Atungulu, G.G., Pan, Z. (2014). Catalytic Infrared and Hot Air Dehydration of Carrot Slices. Journal of Food Process Engineering, 37(2), 111-121.

Manzocco, L., Calligaris, S., Mastrocola, D., Nicoli, M. C., & Lerici, C. R. (2000). Review of non-enzymatic browning and antioxidant capacity in processed foods. Trends in Food Science & Technology, 11(9-10), 340-346.

Bagheri, H., Kashaninejad, M., Ziaiifar, A. M., & Aalami, M. (2016). Novel hybridized infrared-hot air method for roasting of peanut kernels. Innovative Food Science & Emerging Technologies, 37, 106-114.

Azeredo, A.M.C.D. (2011). Coffee Roasting: Color and Aroma-Active Sulfur Compounds. (Doctoral dissertation), Florida, USA: University of Florida.

Syafriandi, F.F., Lubis, A., Maulina, H., & Nazura, P. (2021). Testing coffee roasting machine with electric heater as an energy source. IOP Conference Series: Earth and Environmental Science,

Gothenburg, Sweden.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 School of Renewable Energy and Smart Grid Technology (SGtech)

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

All copyrights of the above manuscript, including rights to publish in any media, are transferred to the SGtech.

The authors retain the following rights;

1. All proprietary rights other than copyright.

2. Re-use of all or part of the above manuscript in their work.

3. Reproduction of the above manuscript for author’s personal use or for company/institution use provided that

(a) prior permission of SGtech is obtained,

(b) the source and SGtech copyright notice are indicated, and

(c) the copies are not offered for sale.