Separating Methane and Carbon Dioxide from Household Biogas

Keywords:

Biogas Separation, Biogas for Household, Methane, Carbon DioxideAbstract

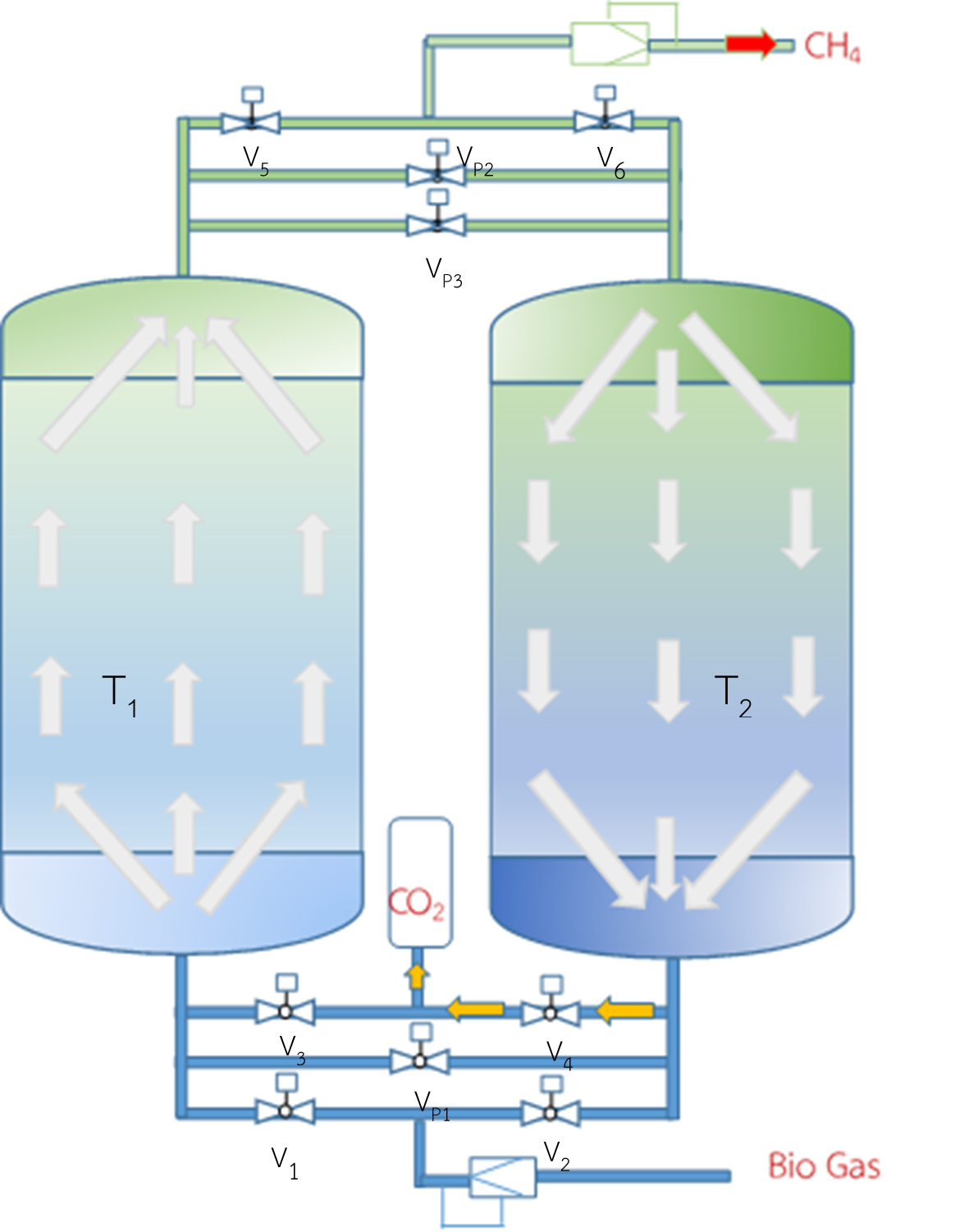

The purpose of this study is to separate carbon dioxide from biogas at different pressures to obtain higher methane concentration for household use by mean of anaerobic fermentation of swine manure to produce biogas in four tanks of 200 liter fermentation tanks and to store in two tanks of 200 liter gas storage tanks. From the study, it was found that behavior of carbon dioxide capture affected in a direct variation. In other words, as gas pressure increased, percentage of carbon dioxide capture would increase also. In the portion of gas flow rate, it affected behavior of carbon dioxide capture in an inverse variation, that is, when gas flow rate decreased, the carbon dioxide capture percentage increased. From the results of the experiment, pressure swing adsorption (PSA) capture techniques were selected to capture carbon dioxide which was captured by molecular sieving carbon with 99.23%maximum CO2 capability before passing through methane separation unit. As for methane separation to increase concentration from the experiment, methane gas was originally contained approximately 65-68 % biogas; after the gas separation process, concentration rose to 98.26 % or about 33.85 % increase from the original concentration. Therefore, if upgrade methane is compressed in a storage container, it can be used in a variety of functions, such as fuel for cars, households cooking and etc.

References

Danbred Genes for Global Pig Production. Retrieved May 20, 2021, from https://www.danbred.com

Wałowski, G. Borek, K., Romaniuk, W., Wardal, W.J., & Borusiewicz, A. (2019). Modern systems of obtaining energy-biogas. In Monograph; Wacław, R., Ed. Warsaw, Poland: Publishing House of the University of Agribusiness.

Paprota, E. (2011) Treatment of biogas as a way of its wider use. AUTOBUSY – Technika Eksploatacja Systemy Transportowe, 10, 329–333.

Aleksandrow, S., & Staniszewska, M. (2013). The importance of renewable energy sources in the global economy and their impact on the labor market. Acta Innov. 6, 41–45.

Ahn, H., Lee, C-H., Seo, B., Yang, J., & Baek, K. (1999, October). Backfill cycle of a layered bed H2 PSA process. Adsorption, 5(4), 419-433.

Romaniuk, W., Głaszczka, A., & Biskupska, K. (2012). Analysis of biogas installation solutions for family and farm farms. In Engineering in Agriculture; Monographs No. 9; ITP Publishing House: Warsaw, Poland.

Kowalski, Ł., & Smerkowska, B. (2012) A Polish case study for biogas to biomethane upgrading. Internal combustion engines, 51(1), 15–24.

Demirbas, M.F., Balat, M., & Balat, H. (2011). Biowastes-to-biofuels. Energy Conversion and Management, 52(4), 1815-1828.

Marszałek, M., Banach, M., & Kowalski, Z. (2011). Manure utilization by methane and aerobic fermentation—Biogas and compost production. Technology Journal, 10, 143–158.

Petersson, A., Wellinger, A., Murphy, J.P., Baxter, D., & Eds, (2013) Biogas Cleaning in the Biogas Hand Book, Sawston, UK: Woodhead Publishing Limited.

Cavenati, S., Grande, C.A., Lopes, F.V.S., & Rodrigues, A.E (2009). Adsorption of Small Molecules on Alkali-Earth Modified Titanosilicates. Microporous and Mesoporous Materials, 121(1-3), 114-120.

Pettersson, A., & Wellinger, A (2009). Biogas Upgrading Technologies – Developments and Innovation. Retrieved April 2, 2011, from http://www.iea-biogas.net/

Dietzel, P.D.C., Besikiotis, B., & Blom, R (2009). Application of Metal-Organic Frameworks with Coordinatively Unsaturated Metal Sites in Storage and Separation of Methane and Carbon Dioxide. Journal of Material Chemestry, 19, 7362-7370.

Abatzoglou, N., & Boivin, S. (2009). A review of biogas purification processes. Biofuels Bioprod. Bioref, 3, 42–71.

Air Liquide (2011). Biogas Recovery System. Retrieved April 2, 2011, from http://www.dta.airliquide.com /en/our-offer/decentralized-energies/biogas.html

Bonnissel, M.P., Luo, L., & Tondeur, D (2001). Rapid Thermal Swing Adsorption. Industrial & Engineering Chemistry Research, 40(10), 2322-2334.

Technical Information. Molecular Sieving Carbon SHIRASAGI “MSC 3K-172”. Retrieved December 11, 2020, from: https:// www.polysource.co.th

Dolan, W.B., & Mitariten, M.J (2003). CO2 Rejection from Natural Gas. United States Patent US 2003/0047071, 2003.

Cavenati, S., Grande, C.A., & Rodrigues, A.E (2005). Upgrade of Methane from Landfill Gas by Pressure Swing Adsorption. Energy & Fuels, 19(6), 2545-2555.

Cavenati, S., Grande, C.A., & Rodrigues, A.E (2006). Removal of Carbon Dioxide from Natural Gas by Vacuum Pressure Swing Adsorption. Energy & Fuels, 20(6), 2648-2659.

Kumanowski, K.S., Szewczyk, K.W., Zamojska, A.M., & Kumanowska, E.J. (2008 November) The Method of Utilizing Liquid Manure by Methane Fermentation and the Installation for Utilizing Liquid Manure by Methane Fermentation. Poland Patent Application P.386459, 6 November 2008.

Cebula, J. (2009). Biogaz purification by sorption techniques. Architect Civil Engineering Environment. 2, 95–103.

Da Silva, F. A. Cyclic Adsorption Processes: Application to Propane/Propylene Separation. Ph.D. Dissertation, University of Porto, Portugal, 1999.

Cavenati, S., Grande, C.A., & Rodrigues, A.E (2008). Metal Organic Framework Adsorbent for Biogas Upgrading. Industrial & Engineering Chemistry Research. 47(16), 6333-6335.

Basmadjian, D. (1997). The Little Adsorption Book: A Practical Guide for Engineers and Scientists; CRC Press.

Piskowska-Wasiak, J. (2014). Treatment of biogas to the parameters of high-methane gas. Nafta-Gaz, 70, 94–105.

Boutin, A., Coudert, F-X., Springuel-Huet, M-A., Neimark, A.V., Ferey, G., & Fuchs, A.H (2010). The Behavior of Flexible MIL-53 (Al) upon CH4 and CO2 Adsorption. The Journal of Physical Chemistry C., 114(50), 22237-22244.

Pomykała, R., & Łyko, P. (2013). Biogas from waste as biofuel for transport—Barriers and prospects. Chemik, 5, 454–45

Skerman, A.G. (2016) Practical Options for Cleaning Biogas Prior to on-Farm Use at Piggeries; A Thesis Submitted in School of Chemical Engineering, Engineering Work; The University of Queensland: Brisbane, Australia.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 School of Renewable Energy and Smart Grid Technology (SGtech)

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

All copyrights of the above manuscript, including rights to publish in any media, are transferred to the SGtech.

The authors retain the following rights;

1. All proprietary rights other than copyright.

2. Re-use of all or part of the above manuscript in their work.

3. Reproduction of the above manuscript for author’s personal use or for company/institution use provided that

(a) prior permission of SGtech is obtained,

(b) the source and SGtech copyright notice are indicated, and

(c) the copies are not offered for sale.